Anguil Announces Industrial Internet of Things (IIoT) Platform, Seeks Pilot Customers

Leave a CommentAnguil has announced the launch of their Industrial Internet of Things (IIoT) software platform and is now seeking participants for their pilot program. Unlike the Internet of Things (IoT), which largely centers on consumer devices, IIoT focuses on bringing connectivity and data exchange capabilities via an internet connection to industrial and manufacturing contexts.

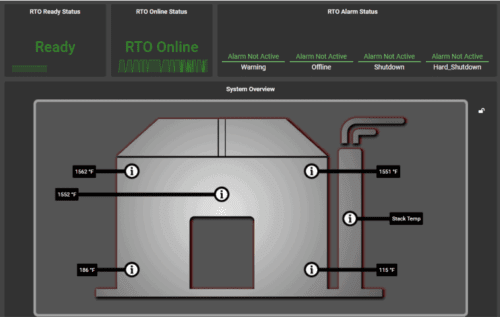

Anguil’s IIoT software platform is tailored specifically for enhancing operational transparency and reporting capabilities for environmental pollution control equipment. Anguil partnered with Siemens to leverage their Mindsphere® software, which provides exceptional data security and complex development components and tools, allowing Anguil to develop a sophisticated, flexible, and data secure IIoT solution. Anguil’s IIoT platform is designed to leverage existing equipment data to improve performance, lower maintenance costs, and prevent unplanned downtime through graphical overviews, KPI dashboards, live trending, and document repositories.

equipment. Anguil partnered with Siemens to leverage their Mindsphere® software, which provides exceptional data security and complex development components and tools, allowing Anguil to develop a sophisticated, flexible, and data secure IIoT solution. Anguil’s IIoT platform is designed to leverage existing equipment data to improve performance, lower maintenance costs, and prevent unplanned downtime through graphical overviews, KPI dashboards, live trending, and document repositories.

According to Richard Oakes, Client Manager and IIoT Business Development Manager, the timing couldn’t be better for Anguil’s IIoT solution: “IoT has disrupted and transformed widespread consumer markets. Why should the environmental pollution control industry be any different? The industry has been mature for a long time – the next logical step is advanced automation and controls. Until now, there really hasn’t been much out there for environmental managers looking to modernize their environmental equipment management strategy. Our IIoT platform is a game changer for them.”

To further test and enhance their IIoT platform, Anguil is seeking industrial facilities with existing environmental technologies to participate in a pilot program. Participants partner with Anguil to integrate the IIoT platform with their environmental equipment for a six-month period, providing feedback on the existing interface and input on desired functionality. To qualify as a pilot participant, Anguil is seeking facilities willing to provide Anguil’s IIoT team technical access to their system control panel. Besides minimal set-up costs, there is no cost to participate as a pilot customer and no long-term obligation. At the end of the pilot program, participants will be offered the option to continue IIoT services or to end the engagement with no pressure to purchase.

For more information on Anguil’s IIoT capabilities and to apply to the IIoT Pilot Program, go to https://anguil.com/engineering-services/industrial-internet-of-things-iiot.

Webinar: Empowering Environmental Technologies with the IIoT

Leave a CommentWebinar: Empowering Environmental Technologies with the Industrial Internet of Things (IIoT)

When: Wednesday December 2, 2020 / 1:00 PM – 2:00 PM CDT (2pm ET / 11AM PT)

Presented by Environmental Energy + Leader, Anguil Environmental is partnering with Siemens to discuss exciting developments in the world of technology and environmental equipment: Empowering Environmental Technologies with the IIoT.

What is the Industrial Internet of Things (IIoT)?

Anguil’s control systems already provide the safest, most efficient, and highly reliable operation while integrating smoothly into existing plant operations. Anguil is now trailblazing the technological advancement of environmental equipment with the Industrial Internet of Things (IIoT) to improve safety, reliability, and maintenance efforts.

This functionality allows personnel inside and outside the plant to communicate with your abatement system using native programming and an internet connection. Real-time data logging, event reporting, and alarm notification are just some of the benefits to IIoT. It is one of the easiest ways to expedite troubleshooting, reduce downtime, and enhance the value of routine preventive maintenance.

This functionality allows personnel inside and outside the plant to communicate with your abatement system using native programming and an internet connection. Real-time data logging, event reporting, and alarm notification are just some of the benefits to IIoT. It is one of the easiest ways to expedite troubleshooting, reduce downtime, and enhance the value of routine preventive maintenance.

What will you learn in this webinar?

- How can you be sure your environmental technologies are in compliance?

- What is the risk of not leveraging sensors and smart devices in decision making?

Manufacturing facilities are increasingly being designed with sensing devices that employ a central control system to remotely monitor and adjust equipment within the plant and beyond. The transparency provided via the IIoT (Industrial Internet of Things) allows companies to analyze and predict machine behavior to optimize production and processes remotely. However, there are costs, time considerations, and potential pitfalls in system selection and implementation. Plant managers, engineers, and production personnel must carefully consider safety, security, and usability of each remotely monitored device. Compliance adds another layer of complexity when talking about IIoT for environmental technologies.

This webinar will examine, in detail, all the benefits and potential hurdles that industrial facilities should evaluate when implementing remote monitoring on environmental technologies.