Anguil has decades of experience supplying alternative heating methods for oxidizer technologies.

While the electrically heated Catalytic Recuperative Oxidizer (CATOX) is well established and widely applied, the industry has been slower to integrate lower carbon components like electric heating elements and hydrogen-fueled burners into the Regenerative Thermal Oxidizer (RTO), Direct Fired Thermal Oxidizer (DFTO), and Thermal Recuperative Oxidizer.

Thankfully, Anguil is at the forefront of low-carbon oxidation solutions with established designs and scalable options for both thermal and catalytic oxidizers.

What Sets Anguil’s Alternative Fuel Oxidizers Apart?

The electrically heated oxidizer has several advantages over burner systems, regardless of the fuel type, including:

- Uniform heat distribution

- Faster installation with reduced wiring and no burner tuning

- Eliminate need for fossil fuels — smaller footprint

- Scalability, allowing for extra heating capacity if needed

- No fuel train requirements

For customers with hydrogen capacity, we also offer specialty burners for hydrogen, which eliminate SOX and CO2 emissions with near-zero NOX output when compared to natural gas. Anguil also has the capability of providing Liquified Petroleum Gas (LPG) and renewable natural gas systems.

-

Product Overview

Benefits of Anguil’s Alternative Fuel Oxidizers

When compared to traditional fossil fuel combustion systems, these industry leading technologies offer:

- Lower Carbon Footprint

- Faster Installation

- Enhanced Flexibility During Low-Flow Conditions

- Reduced Maintenance & High Reliability

- Comparable Capital Costs

-

Electric RTO Features

Features of Anguil’s Electrically Heated RTO

When compared to traditional natural gas fired combustion systems, this industry leading technology offers:

- Reduces greenhouse gases produced from fossil fuel heating source (NOx, CO2, SOx)

- High thermal efficiency to reduce heater sizing

- High VOC destruction efficiency

- No products of incomplete fossil fuel combustion

- Eliminates need for gas connections, fuel trains, burners and combustion air fan

- Same footprint as a gas fired RTO

- Dual heating source functionality is an option for redundancy

-

Ideal Applications

Ideal Applications

- Facilities following ESG (Environmental, Social, Governance) standards

- Facilities lacking fossil fuel access

How Does an Alternative Fuel Oxidizer Work?

Oxidation is the process by which hydrocarbons are broken down into carbon dioxide and water vapor through oxygen and heat. A general equation showing this relationship is presented in the equation below:

Cn H2m + (n + m/2) O2 → n CO2 + m H2O + Heat

The particular n and m subscripts of the equation are used to define the number of carbon atoms and hydrogen atoms. The number of oxygen atoms convert to n molecules of carbon dioxide and m molecules of water vapor and heat.

This equation highlights the oxidation reaction that is occurring in a gas fired burner that is historically used in thermal and catalytic oxidizers. The oxidation equation for burning natural gas (methane) is shown in the below equation:

CH4 + 2 O2 → CO2 + 2 H2O (+ Heat + NOx)

(CO2 and NOx removed when using electric heat source)

In addition to the formation of CO2, NOx is also produced due to the high temperature of the burner flame. Replacing a gas fired burner with an electric heater eliminates the CO2 and NOx that is generated from the heating source. CO2 will still be produced from the oxidation of the VOCs themselves in either a gas or electrically heated RTO.

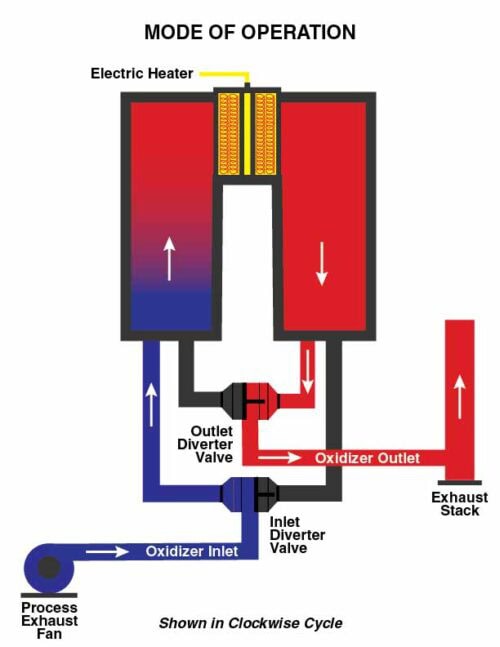

How Does an Electric RTO Work?

The VOC-laden process gas enters the oxidizer through an inlet manifold to flow control poppet valves that direct this gas into energy recovery chambers where it is preheated. The RTO is equipped with two beds of ceramic media which serve as heat sinks, scavenging much of the thermal energy from the process stream as it exits the oxidizer cooling the exhaust steam and heating the media. The process gas and contaminants are progressively heated in the ceramic media beds as they move toward the combustion chamber.

Once oxidized in the combustion chamber, the hot purified gas releases thermal energy as it passes through the media bed in the outlet flow direction. The outlet bed is heated, and the gas is cooled so that the outlet gas temperature is only slightly higher than the process inlet temperature. Poppet valves alternate the airflow direction into the media beds to maximize energy recovery within the oxidizer. The high energy recovery within these oxidizers reduces the auxiliary energy input requirement from the electric heater and saves operating cost. The Anguil oxidizer achieves high destruction efficiency and self-sustaining operation with no auxiliary energy input to the electric heater at concentrations as low as 3-4% LEL (Lower Explosive Limit).

Hydrogen-Fueled Oxidizers

For customers with hydrogen capacity, Anguil also offers specialty hydrogen fueled burners which eliminate SOx and CO2 emissions with near-zero NOx output. Many commercial burner suppliers have designed their burners to be able to operate on either natural gas or hydrogen with minimal changes.

Anguil can offer all the benefits of this lower carbon footprint fuel, with the same high-energy recovery and destruction efficiencies seen from using natural gas burners.

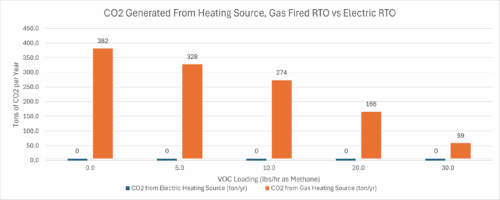

Greenhouse Gas Reduction in an Electric RTO

The benefits of an electrically heated RTO is apparent when looking at the CO2 and NOx production estimates against a traditional natural gas fired RTO. Anguil has compared our standard Model 50 Two Bed gas fired RTO against our Model 50 electrically heated RTO with the same process conditions (5,000 SCFM process flow at 70°F and 8,760 operating hours per year). The CO2 generated in tons per year from the natural gas fired burner has been charted against the VOC loading in the process (Chart #1).

This only considers the CO2 generated from the burner itself, not the CO2 produced from the oxidation of the VOCs. Using an electric heater in the RTO eliminates the CO2 produced from the heating source.

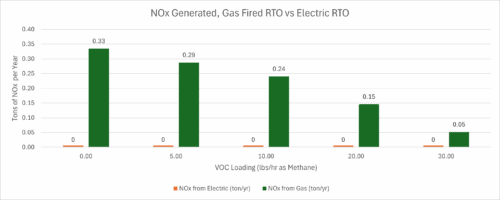

Similarly, the NOx generated in tons per year from the natural gas fired burner has been charted against the VOC loading in the process (Chart #2). This assumes that there are no nitrogen bearing VOCs present such that the only NOx produced is from the burner flame. The electrically heated RTO does not produce any NOx in comparison.

Want to determine whether an alternative fuel oxidizer is for you?

Contact Anguil Environmental for a free technology analysis. Anguil would be pleased to provide a preliminary technological analysis between a gas fired oxidizer versus an alternative fuel oxidizer. Included in that analysis will be an estimate for both capital and operating costs, as well as utility use numbers.