The Challenge

Our planet is getting warmer. At what rate it is occurring or how much human activity has to do with the increasing temperatures is a heated debate. One thing we do know for sure is that Carbon Dioxide (CO2) is a contributing factor in global warming and humans are responsible for a large portion of these emissions. These days, many individuals and businesses alike are trying to reduce their environmental impact and GHG (Green House Gas) emissions. What the average person does not realize is that they have two types of footprints, a primary and secondary. The primary footprint is a measure of our direct emissions of CO2 from the burning of fossil fuels including domestic energy consumption and transportation, e.g. car and plane. The secondary footprint is a measure of indirect CO2 emissions from the whole lifecycle of products we use, those associated with their manufacturing and eventual breakdown. To put it simply: the more we buy, the more emissions will be caused on our behalf.

The Solution

Thankfully companies like Corus, a subsidiary of Tata Steel, are doing their part to reduce the world’s secondary footprint by improving the energy efficiency of their manufacturing processes. Corus is Europe’s second largest steel producer and comprises three operating divisions: Strip Products, Long Products, and Distribution and Building Systems. Corus Colors as part of the Strip Products Division is an international business manufacturing pre-finished steel for the building envelope, domestic appliances and manufactured goods markets.

This manufacturing process requires large amounts of natural gas to ensure proper application and fast curing time in the ovens, which, in turn generates a substantial amount of CO2 and NOX (Nitrous Oxides). In addition to these emissions, the solvent-based coatings release HAPs (Hazardous Air Pollutants) and VOCs (Volatile Organic Compounds) during the drying process that need to be treated by an air pollution control device such as an oxidiser. New oxidiser systems are capable of destroying over 99% of the HAPs and VOCs through the process of high temperature destruction with very little fuel consumption. However older technologies can be a source of CO2 and NOX as well as the requirement for high maintenance and large operating expenditures.

The Result

Looking for a sustainable energy solution, they turned to Spooner Industries in the United Kingdom who have worked closely with Corus on a number of projects over the past 30 years. Oven technology and safety regulations had changed dramatically since the line was first installed, but Spooner was able to successfully complete several upgrades that brought the system up to current standards and increased its flexibility.

- Each zone was retrofitted with a special low NOX burner to reduce emissions.

- Variable frequency drives or inverters on every oven fan were incorporated into the control system to make each section more efficient and reduce electrical consumption.

- The ductwork was changed to bring hot air into the system quickly, reducing maintenance issues.

- New thermocouples (temperature measurement), pressure transmitters, pressure switches and flow measurement systems were installed in the ovens to bring the equipment up to today’s technology standards, allowing for remote monitoring and fine-tuning.

- A new computer controlled system was integrated with the SCADA (System Control and Data Acquisition) program. The proper PLC (Programmable Logic Controller) allows the central Corus system to communicate with the ovens so they can be set up for different production runs, eliminating errors and decreasing setup time.

The oven alterations brought this production line from the least efficient in the Corus group to the most, meeting one of the two objectives for the company. While some of these improvements reduced the company’s environmental footprint and gas consumption, the increased throughput would further complicate their environmental responsibilities. Two existing, inefficient oxidisers for the Prime and Finish Ovens were being used to control VOC and HAP emissions at the North Wales facility. To achieve proper destruction the systems required large amounts of natural gas which affected operating expenses and contributed to CO2 and NOX emissions. Furthermore, breakdowns and maintenance problems were not only costing the company money to repair but also revenue in lost production. Because the oven and oxidiser are so vital to each other, Corus wanted a solution provider with experience and knowledge on both. In addition, they were looking for a system with low operating costs and heat recovery capabilities that could achieve 99.5% DRE (Destruction Removal Efficiency) which was well above their permit requirements.

Spooner, having recently partnered with Anguil Environmental Systems in The United States to fabricate and install their oxidiser designs on applications throughout Europe, was confident that it could be done. After consulting with the engineers at both Spooner Industries and Anguil Environmental Systems, Corus made the decision to replace their multiple air pollution control systems with one, RTO (Regenerative Thermal Oxidiser) from Spooner Anguil. It would give them the desired efficiency and single-source solution they were looking for. The system has the following features and benefits:

- The oxidiser is a 3-chamber design that processes 83,000 Nm3/hr (55,000 SCFM) of air, achieving 99%+ DRE without visible emissions and 85%+ heat recovery for energy-efficient operation.

- The RTO self-sustains at low solvent-loading conditions, meaning that once the oxidiser is at operating temperature and receiving process airflow it requires no additional fuel for emission destruction, releasing very little CO2 and NOX.

- A secondary heat exchanger sends waste heat directly back to the ovens, reducing the amount of natural gas required for product curing.

- Stainless-steel components throughout the system prevent corrosion and allow for high temperature process streams.

- A hot-gas bypass on the RTO is used during high loading situations to avoid overheating the oxidiser.

- An intelligent bake-out feature cleans the RTO of condensable organics without internal fires or safety concerns.

- The control panel has a large operator screen with a built-in maintenance manual and troubleshooting guide which makes for ease of use.

- Corus has made a significant investment for the new equipment, upgrades and implementation of this energy reduction project. It has dropped their cost, per ton of steel produced, considerably and they estimate the payback will be less than one year.

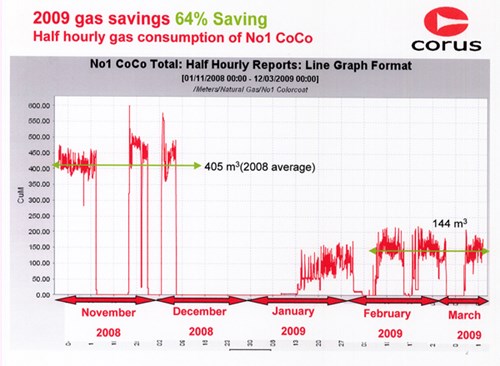

The reduction in carbon emissions and energy consumption from this facility is dramatic. Their gas usage has dropped by more than 60%, an average reduction of 522 m³/hr (or 5742 kW) per hour – saving over £1million a year. At 181 grams of CO2 produced per KWH used, Corus is preventing 1 tonne of carbon from reaching our atmosphere each hour, nearly 8,000 tonnes per year.

With innovation and continuous improvement at the heart of its business, the company is already planning for similar modifications at other Corus plants. A spokesperson from Corus commented: “We are committed to minimizing the environmental impact of our operations and our products through the adoption of sustainable practices and continuous improvement in environmental performance.”