The Challenge

As individuals and corporations continue to push towards smaller carbon footprints, the use of Lithium-Ion Batteries (LIBs) has become increasingly prevalent. Specifically for individuals, the utilization of battery packs for all-electric automobiles and solar-powered home battery banks have continued to grow at a rapid rate. The manufacturing of these battery packs generates several air pollutants that must be treated prior to being released to atmosphere.

As individuals and corporations continue to push towards smaller carbon footprints, the use of Lithium-Ion Batteries (LIBs) has become increasingly prevalent. Specifically for individuals, the utilization of battery packs for all-electric automobiles and solar-powered home battery banks have continued to grow at a rapid rate. The manufacturing of these battery packs generates several air pollutants that must be treated prior to being released to atmosphere.

One large supplier of LIBs faced a unique set of challenges at their main production facility.

- Three identical abatement systems were required, capable of handling up to 35,000 SCFM of emission laden air each. Electrically heated air pollution control systems are typically much smaller.

- Fossil fuels (natural gas, propane, fuel oil, diesel, etc.) of any kind are not allowed in the factory.

- Process gases consist of both ambient and hot air streams, both with very low concentrations.

- All abatement systems were to be installed indoors on the third floor of the factory with very tight footprint and height constraints.

Manufacturing of complete LIBs requires several different processes and operations that produce Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) at varying temperatures. For instance, making battery electrodes uses N-Methyl Pyrrolidone (NMP) which is a solvent the manufacturer can recover and reuse without treatment in a pollution control device. However, this supplier had additional module manufacturing lines and multiple e-coat paint lines with curing ovens where solvent recovery was not an option. This further complicated the compliance solution.

The Solution

Anguil was tasked with developing a compliance solution to capture and treat 70,000 SCFM of emission laden air with the following requirements:

Anguil was tasked with developing a compliance solution to capture and treat 70,000 SCFM of emission laden air with the following requirements:

- Achieve a minimum 90% overall air pollutant reduction

- Any heating requirements must be achieved without the use of any fossil fuel

- Provide an n+1 arrangement for system redundancy during maintenance

- Minimize all utility consumption to the greatest extent possible

- Reduce overall system footprint, height, and weight to fit within facility restraints

Anguil is one of the few industrial air pollution control providers that offers a full line of thermal and catalytic oxidizer technologies that also includes emission concentrators. The diverse technology offering allowed Anguil to evaluate each option and its applicability for the demanding project objectives.

The first decision was to route all ambient process air sources to a zeolite concentrator wheel. The wheel uses a zeolite substrate to adsorb the VOCs and HAPs out of the process gases and onto the concentrator surface. A heated stream, approximately 10% the original volume, is used to desorb the pollutants from the wheel. The result is a highly concentrated stream that is one-tenth the original volume. This significantly reduces the size, capital and operating costs of the downstream oxidizers that are paired with the concentrator wheel.

Anguil engineers made the decision to utilize Regenerative Catalytic Oxidizers (RCO) with electric heating elements to treat both the hot process stream from their curing ovens and the concentrated air stream from the concentrator wheel. This technology combination is often referred to as an RCTO. Employing catalyst inside a thermal oxidizer allows emission destruction to occur at much lower temperatures; 600-800°F (315-427°C) versus 1,400-1,500 °F (760-816°C). The lower operating temperature also provides for a much more reliable and smaller (physical size and KW rating) electric heating element. The RCO uses ceramic blocks as the heat transfer media allowing for 97% Thermal Energy Recovery (TER) from combustion. The combination of lower operating temperature and 97% TER made the RCO the best choice for minimizing utility consumption and ensuring low maintenance operation.

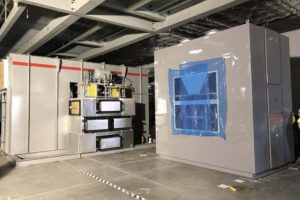

All three oxidizer systems and the concentrator wheel were to be installed inside on the 3rd floor of a building still under construction under an existing mezzanine that provided only 15’ of overhead clearance. Anguil designed all individual pieces so they could be lifted three stories using an external elevator and fit through a narrow overhead door. All three units were installed inline and connected via common inlet and outlet manifolds to reduce installation costs.

Once installation was complete, Anguil’s start-up technicians arrived onsite to complete final commissioning. Anguil’s technicians conducted operator training consisting of both “on skid” and classroom sessions. Test data has shown each of the systems is achieving greater than 90% overall emission removal and 97% TER.

The Result

- Anguil was able to listen to the customer’s needs and the unique requirements of an oxidizer system that can process up to 70,000 SCFM of VOC-laden air without the use of fossil fuels.

- The zeolite concentrator wheel was applied to the ambient temperature sources, greatly reducing the size of the downstream oxidizers and the associated utility requirements.

- Selecting an electrically heated RCO eliminates the need for a fossil fuel fired burner, a customer requirement. The use of catalyst allows the oxidizer to operate at a much lower temperature than a thermal oxidizer, minimizing the size of the electric heating element. The RCO was also designed with 97% TER, further reducing the utility requirements and the size of the heating element.

- The hot source from the cure oven was sent directly to the RCO inlet, having no negative impact on the operation and efficiency of the concentrator wheel.

- Supplying three identical systems each sized to process 35,000 SCFM allows the customer to process up to 70,000 SCFM of VOC-laden air while operating in the required n+1 arrangement.

- Each system was designed to minimize the footprint and height to the greatest extent possible, saving on valuable floor space inside the facility.

- The system efficiency and effectiveness have exceeded the design specifications.