This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The Challenge

OXIDIZER SERVICE SERIES: PART 1

Part of properly servicing your oxidizer system is maintaining the design documentation associated with that system. When it comes to oxidizer design, National Fire Protection Association (NFPA) standards are considered good practice, and those same standards include requirements that should be used for ongoing oxidizer maintenance and system documentation.

The Solution

The following are critical design documents oxidizer users should preserve that contain information required by the NFPA to implement an overall system reliability plan. Anguil uses the same documents to build and maintain information to offer value-added service on anyone’s oxidizer system, regardless of the original manufacturer. The documents listed with an asterisk (*) are the three most important documents to have on hand and you should always have print copies inside your control panel.

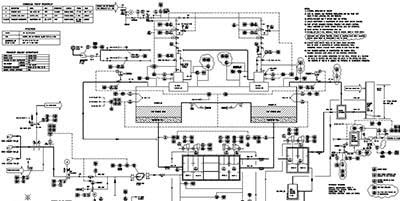

- Process and Instrumentation Diagram (P&ID):The P&ID is the command drawing that summarizes instrumentation, safety devices, operational limits, and control loops. The P&ID typically provides the oxidizer component tag numbers, as well as the number and type of process exhaust pick-ups for the system. The system utility requirements and performance parameters can be listed as well.

- Electrical Schematics:The electrical schematics provide the detailed connectivity of the entire system and is an important tool used for system troubleshooting. It is critical that the electrical schematics are not only kept readily available, but also revised to keep up with system changes.

- Sequence of Operation / List of Set Points & Alarm Conditions:The sequence of operation is a step-by-step description of how the oxidizer is designed to operate. It includes: how it starts, how it brings process exhausts on-line, how it maintains airflow and temperature control, and how it safely shuts down. Set points and alarm conditions of the system are also included in this document. It is important to note that this documentation is required per the National Fire Protection Association’s NFPA 86: “Wiring diagrams and sequence of operations for all safety controls shall be provided” (From NFPA 86: Standard for Ovens and Furnaces, 2019 Edition – Section 4.1.1.2).

- Programmable Logic Controller (PLC) Program: If your system requires a PLC, we recommend you keep a fully documented copy of your PLC program for your records. It is important to know that some oxidizer suppliers may be reluctant to release this information to system end-users because PLC programs can include proprietary control schemes. However, with a signed confidentiality agreement in place, end users should be able to obtain this code. If your oxidizer manufacturer is no longer in business, it is possible to upload the program directly from the PLC, but it may be undocumented and you may need an oxidizer service provider to re-enter the code documentation. Information on Anguil’s PLC programming capabilities can be found here.

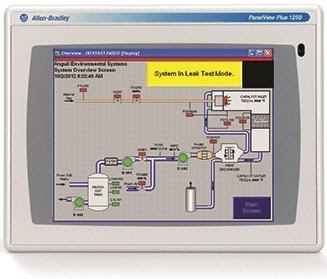

- Human Machine Interface (HMI) Program:The HMI (Operator Interface / Operator Touch Screen) is the operator’s window into the workings of the oxidizer’s PLC. The HMI program goes hand-in-hand with the PLC program to control your oxidizer system by displaying data points from the PLC along with set points and tuning parameters the operator will be allowed to adjust from the HMI. The HMI also provides system status messages and/or alarm messages based on the PLCs outputs. A failed display can leave you essentially blind when it comes to operating your oxidizer system safely. If this happens at an inopportune moment, you want to be prepared to download your HMI program to a replacement display from your spare parts inventory.

- Expected Pressure-Temperature Profile:This is one of the more obscure documents to obtain, however, it is pivotal in the development of a reliability plan for your system. Obtaining this information can be as simple as a small table on the P&ID giving the expected temperature and pressure value at various points throughout the oxidizer. It is critical to know your pressure point values in order to set up a regular inspection plan for your maintenance personnel. Ideally, you should have a table showing expected pressure and temperature data at the common process exhaust airflow amounts your production requires. If this is unknown, ask your system provider to provide data for two conditions: at full-oxidizer airflow capacity and at half-oxidizer airflow capacity. Once provided this information, you will be able to approximate the points in-between when establishing your customized inspection checklists.

- Permit Compliance Documents:Compliance documentation requirements vary greatly across local, state, and federal agencies, making it difficult to provide generalized recommendations appropriate for all operation scenarios. At a minimum, Anguil highly recommends summarizing your permit compliance documentation requirements within a single, concise document that includes minimum and operating temperatures and bypass limitations. This document will keep all parties aware of the key compliance parameters to monitor and record with respect to your oxidizer system.

- Bill of Materials / Recommended Spare Parts Lists:Finally, a complete bill of materials for your oxidizer system will allow you to obtain the parts you need to maintain system operation. Ideally, the parts listed in the Bill of Materials would be further categorized as “Critical Spare Parts,” “Recommended Spare Parts,” “Consumable Spare Parts,” “Convenience Items,” “Long Lead Time Components,” etc. This allows operators to make an informed decision on the type and quantity of spare parts to stock based on specific production and compliance requirements. Some air permits actually require that critical spare parts be kept on hand. More detailed information on these categories can be found on the Spare Parts section of our website.

ADDITIONAL INFORMATION

ADDITIONAL INFORMATION

Here are some additional highlights regarding system documentation from the current edition of NFPA 86 Standard for Ovens and Furnaces 2019 Edition:

4.1.1.1 Plans shall be drawn that show all essential details with regard to location, construction, ventilation, piping, and electrical safety equipment. A list of all combustion, control, and safety equipment giving manufacturer and type number shall be included.

4.1.1.2 Wiring diagrams and sequence of operations for all safety controls shall be included.

7.3.3 Operating instructions that include all of the following shall be provided:

(1) Schematic piping / wiring diagrams

(2) Startup procedures

(3) Shutdown procedures

(4) Emergency procedures

(5) Maintenance procedures

7.3.4 When the original equipment manufacturer no longer exists, the user shall develop inspection, testing, and maintenance procedures.

The Result

This is the first of four parts in Anguil’s Oxidizer Service Series. We encourage you to also view Part 2: Crafting Your Oxidizer Maintenance Plan as well as Part 3: Stocking Spare Parts for Your Oxidizer System and Part 4: Oxidizer System Optimization.