Industrial Wastewater Solutions Overview

Most industrial facilities produce some volume of wastewater, which can range from 1 gallon per minute to millions of gallons per day. To protect the soil and groundwater from contamination, industrial wastewater treatment solutions must be efficient while meeting environmental standards. Read on to learn more about industrial wastewater treatment processes and what options are available for your application.

Industrial Wastewater

To minimize the effects of highly contaminated wastewater on the environment, many industrial facilities have to implement wastewater pretreatment plants that treat industrial wastewater to acceptable standards for discharge to a municipal wastewater treatment plant or to the surface (into lakes or rivers). These pretreatment plants remove solids, VOCs, metals, fats oils, and grease such that the final effluent is compliant with local and national laws and regulations. Industrial facilities must also properly dispose of solids that the waste treatment process generates or removes.

In the United States, total water use is estimated at around 322 billion gallons per day. Industrial applications use nearly half of that total. To ensure compliance with existing laws, facilities must adequately manage any organic and inorganic pollutants generated during production processes that might otherwise contaminate water supplies. Different kinds of wastewater contamination will need different strategies to facilitate the proper removal of contaminants.

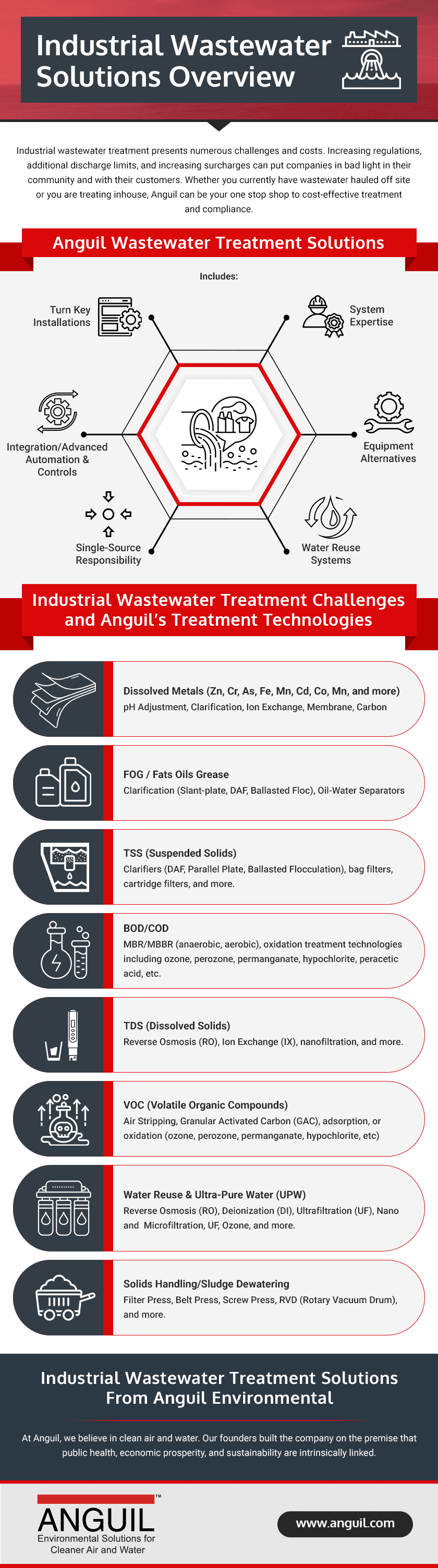

Industrial Wastewater Treatment Solutions

The primary focus of most wastewater treatment solutions is to discharge wastewater in compliance with national and local regulations. The secondary goal is to be as cost-effective as possible in the treatment of wastewater.

Anguil’s project approach has 4 distinct steps that lead to project execution. Project development entails understanding a client’s needs and respective decision criteria. Next, lab trials focused on meeting those criteria are executed in the Anguil lab. If conditions dictate, Anguil is prepared to do pilot testing at the client site. Through our lab and pilot testing, we can validate different technologies and treatment approaches to meet their needs, including capital cost (CAPEX) and operational cost (OPEX) comparison. If needed, we can provide automated options to reduce human involvement. We can even provide options for water reuse, ZLD (zero liquid discharge), or near-zero liquid discharge.

The project execution phase could include fully engineered, build-to-specification, turnkey, and customized solutions. In lieu of new equipment, execution may be retrofits or system upgrades.

At Anguil, our industrial wastewater solution capabilities include:

- System Expertise

- Equipment Alternatives

- In-House Capabilities

- Single-Source Responsibility

- Integration Capabilities

- Experience

Industrial Wastewater Treatment Solutions: Technologies

Industrial wastewater solutions use a variety of technologies. The following are some of the materials these systems remove and the technologies used to remove them:

- Dissolved metal materials can be removed through pH adjustment and clarification, ion exchange, and carbon technologies.

- Fats and oils/grease can be removed with dissolved air flotation (DAF) and oil-water-separators.

- Sludge dewatering happens when water is squeezed from sludge using filter presses, belt presses, rotary vacuum drums, and rotary screw presses.

- Suspended solids are removed by cartridge filters, ballasting, parallel plate clarifiers, DAF, flocculation, and bag filters.

- Soluble biochemical oxygen demand (BOD)/chemical oxygen demand (COD) is eliminated with MBBR, MBR, anaerobic, anoxic, bioreactor, and oxidation treatment.

- Total dissolved solids (TDS) are the measurement of the total dissolved amount of organic and inorganic solid materials present in wastewater. Reverse osmosis, ion exchange systems, and nanofiltration facilitate the removal of TDS.

- Volatile organic compounds (VOCs) are often present in wastewater, requiring removal via air stripping, granular activated carbon (GAC) adsorption, or oxidation.

- Ultra-pure water requires the removal of minerals and other contaminants from relatively clean water. Reverse osmosis (RO), deionization (DI), ion exchange, ultrafiltration (UF), and microfiltration are a few technologies that can be leveraged to create ultra-pure process waters.

Industrial Wastewater Treatment Solutions From Anguil Environmental

At Anguil, we believe in clean air and water. Our founders built the company on the premise that public health, economic prosperity, and sustainability are intrinsically linked. If you would like more information about industrial wastewater treatment, contact us today!