Anguil Environmental Systems received a request to quote an oxidizer and packed tower air stripper to treat a 65 gallon per minute water stream containing significant concentrations of Diesel Range Organics (DRO), Volatile Organic Compounds (VOCs) and some Total Suspended Solids (TSS). The customer’s overall project goals were to reduce facility emissions, ideally to zero, as well as minimize the maintenance activities they were conducting on their cooling tower heat exchangers due to fouling from the process water.

Application engineers at Anguil determined that a Regenerative Thermal Oxidizer (RTO) would meet the customer’s needs but were skeptical that the air stripper would function properly given the customer supplied water characteristics. Anguil Aqua was engaged to evaluate the water stream for the air stripping application. Their review of the supplied water analysis indicated that concentrations of heavier organics Diesel Range Organics (naphthalene and higher) were beyond their solubility limits. Hence, the presence of free product in this water stream would quickly cause any air stripper to foul, detrimentally impacting stripping performance and potentially creating a safety hazard. Anguil Aqua recommended that the customer evaluate oil/water separation and emulsion breaking to remove and potentially recover the free product prior to entering the air stripper.

Using water samples, an initial bench evaluation of oil/water separation was conducted. Upon receiving the samples, Anguil realized that either the supplied water analysis had been done incorrectly or that the water samples received were not characteristic of the analysis since the presence of free product was not observed. The emulsion breaking tests were performed anyway, predictably meeting with little success. In addition to the emulsion breaking tests, Anguil attempted to coagulate the water to determine if this approach would be suitable and determined that this method had merit.

Based on results from the initial separation study, Anguil recommended two courses of action. First, the customer would re-perform their analytical analysis on the water which was to be treated using suggested EPA test methods to improve confidence in the treatment design requirements. Secondly, Anguil suggested that a two stage pilot study be conducted. For Stage 1, Anguil representatives would perform treatability studies on site via jar testing. Based on the results obtained from Stage 1, Anguil engineers would perform a full scale, onsite pilot with the appropriate equipment for Stage 2.

Stage 1 Anguil representatives traveled to the site and performed jar tests directly with the process water in question. Since the process water is at a temperature of 110-120 oF, it was advantageous to work with the process directly rather than trying to use samples which have cooled during shipment to the lab possibly compromising the process characteristics. After a number of trials, they successfully determined that the water could be coagulated by raising the pH from 4 to 8.5, utilizing a poly aluminum chloride (PAC) based coagulant blend and a standard polymer. After coagulation and filtration, color, turbidity and solids content were reduced. Anguil then sent out the untreated and treated water for analysis to determine the overall effectiveness of the process. The results were promising and the customer elected to move forward with Stage 2 of the pilot study.

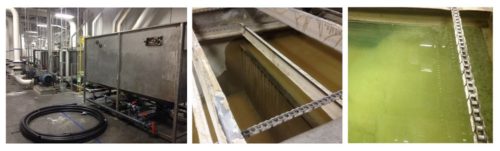

Stage 2 Based on the site constraints and treatment goals, Anguil modified its custom pilot clarification system to perform the second stage of the study. Equipment arrived onsite, unloaded and placed within the facility. A generator was rented since the facility could not easily supply the required power. Anguil then proceeded to unpack and plumb the pilot system into the existing process piping.

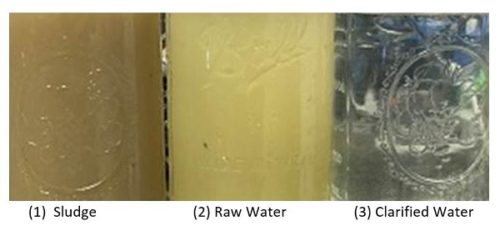

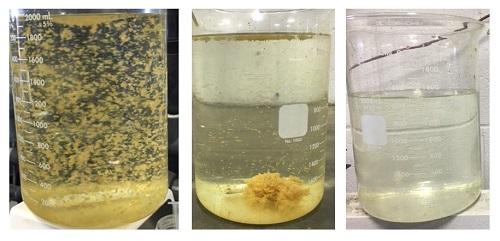

Once everything was set-up, pumps primed and running, the operator filled the tank with process water and began processing using the chemical formula determined in Stage 1: Raise pH > 8.5 using 50% caustic solution, add 300 ppm coagulant, add 1 ppm polymer. As expected, the clarifier influent demonstrated a good floc which quickly began to settle to the bottom of the clarification tank. With continued processing, clarity improvements in the clarification tank became noticeable as submerged parts of the tank became visible as the initial dirty water was displaced by the coagulated and clarified water. Water samples pulled from the clarifier effluent were obviously cleaner than the raw process water, and with continued processing acceptable clarity was achieved.

After successfully demonstrating the clarification process, treated samples were pulled and tested using the same test protocol used in Stage 1. In addition, a sludge sample was sent for benzene analysis in order to determine if the sludge would be considered hazardous. Sludge production rates were quantified by coagulating, flocculating and filtering specific volumes of process water. Filtered samples were wrung dry and air dried for several days. Wet and dried samples were weighed.