Mining operations face unique environmental challenges, from managing ventilation air methane (VAM) emissions to treating complex wastewater streams. Anguil Environmental delivers comprehensive air and water pollution control solutions designed to meet the rigorous demands of the mining industry.

Our engineering expertise and adaptable technologies ensure compliance, reduce emissions, and enhance operational efficiency, allowing you to focus on safe and productive mining activities.

Common Applications

Anguil’s pollution control systems are engineered to address the specific challenges of mining operations. We collaborate closely with your team to conduct site evaluations and testing, ensuring each solution is tailored to your operational needs.

Ventilation Air Methane (VAM) Abatement

Underground coal mining relies on ventilation systems to maintain safe working conditions, resulting in the release of large volumes of air containing low concentrations of methane. While methane concentrations are typically low, 0.2%CH4 to 1.5% CH4 the sheer volume of ventilation air makes VAM a significant source of greenhouse gas emissions, with a disproportionately high climate impact (29 times that of CO2 emissions).

Anguil’s VAMTOX systems (a specialized form of Regenerative Thermal Oxidizers or RTOs) are designed specifically for these high-flow, low-concentration streams. They operate using the energy of the methane with zero additional fuel required as low as 0.2% CH4 and provide reliable methane destruction of 98%+ while offering opportunities for energy recovery, and even power generation in some cases, helping mines reduce emissions, improve project economics, and meet evolving regulatory expectations while avoiding carbon taxes and gain CO2 credits for potential trading.

Carbon Management and Emission Reduction

In regions such as Australia and China, federal carbon pricing programs now require mine operators to pay for each ton of CO₂ equivalent emitted to the atmosphere, with rates escalating over time. These policies significantly impact long-life mining operations, particularly metallurgical coal mines supporting energy-intensive industrial processes.

By implementing methane reduction and emission control technologies, mine operators can reduce or avoid carbon tax liabilities while generating tradable carbon credits that help offset production costs. Additional state-level initiatives further increase incentives for mines to invest in emission reductions and support meaningful local climate outcomes.

Wastewater Treatment in Active and Abandoned Mines

Mining processes generate wastewater containing contaminants like cyanide, heavy metals, and suspended solids. Anguil’s customized treatment trains, including pH adjustment, chemical precipitation, and filtration, ensure safe discharge and water reuse.

Remote and Variable Operations

Mining sites often operate in remote locations with fluctuating emission levels. Anguil’s modular and flexible systems are designed to adapt to varying conditions, ensuring consistent performance and compliance.

This list highlights common applications, but it’s not exhaustive. Anguil frequently designs custom systems and integrates multiple treatment technologies to meet the unique pollution control demands of each facility. If your process isn’t listed above, contact us. Our team is ready to help you identify the right solution for your specific application.

-

Solutions In Action

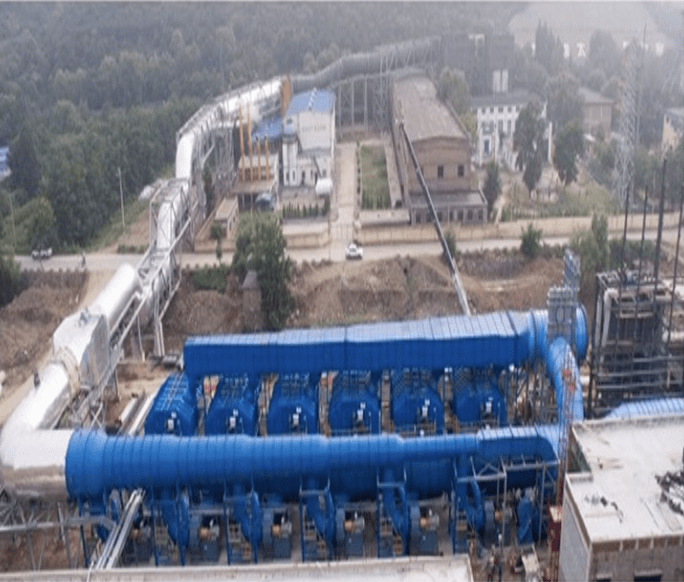

HARNESSING METHANE EMISSIONS FROM COAL MINING

Ventilation Air Methane (VAM) refers to the ventilating exhaust from coal mines with methane concentrations between 0.1 and 1.9%. Although the concentration is extremely low, the volume of VAM flow is extremely large.

Learn More

Trust Anguil with Your Pollution Control Systems

With decades of experience in the mining industry, Anguil delivers reliable and efficient pollution control solutions tailored to your specific needs. Our commitment to engineering excellence and customer-focused service ensures that your facility meets environmental regulations while maintaining optimal operational performance.

Mining Operations Pollution Control FAQs

How much additional fuel is required to operate an RTO at with a VAM stream at 0.2% Methane?

Zero

Have RTOs been used on VAM emissions, if so for how long?

Yes since 2019

What reduction of Methane will RTOs achieve?

98%+

Resources

- EPA’s Coalbed Methane Outreach Program (CMOP), to which Anguil is a certified partner, has worked cooperatively with the coal mining industry throughout the world to reduce methane emissions from mining activities.

- EPA’s Landfill Methane Outreach Program (LMOP), to which Anguil is a certified partner, is a program that works cooperatively with industry stakeholders and waste officials to reduce or avoid methane emissions.

- The Global Methane Initiative (GMI) is an international network of countries as well as public and private companies like Anguil dedicated to the recovery and use of methane as a clean energy source from biogas, coal mines and the oil/gas operations.

Solutions by Pollution Type

Anguil offers a comprehensive suite of air pollution and water pollution control technologies specifically designed for mining operations. Our solutions are engineered to address methane emissions—including ventilation air methane (VAM)—particulates, and complex wastewater streams with precision and reliability.

Air Pollution Control

Anguil’s air pollution control solutions are specifically engineered to address the emission challenges common in mining operations, where processes often produce methane and other hazardous air pollutants. Our Regenerative Thermal Oxidizers (RTOs), including specialized VAMTOX configurations for ventilation air methane (VAM) abatement, offer reliable destruction efficiency while supporting energy recovery opportunities. Designed for maximum uptime and consistent performance, these systems help mines meet stringent air quality regulations while minimizing energy consumption and operating costs.

Water Pollution Control

Anguil’s water treatment solutions are designed to manage the complex wastewater streams generated by mining operations, which often contain cyanide, heavy metals, and other contaminants. Our technologies—including pH adjustment systems, chemical precipitation units, and advanced filtration methods—are tailored to ensure compliance with stringent discharge regulations while enhancing overall process efficiency. In applications such as tailings management and mine dewatering, these systems play a critical role in maintaining environmental compliance, reducing water usage, and supporting consistent production output.