Under new regulations from the Environmental Protection Agency (EPA), sterilization companies that utilize Ethylene Oxide (EO) have until April 2026 to ensure pollution control technologies are in place to remove up to 99.99% of the emissions coming from aeration rooms, sterilization chamber exhausts, and back vents, or shut down production.

Meeting and measuring to these strict standards will be challenging. Many sterilizers are scrambling to purchase new combustion systems and monitoring devices to meet the deadline, but two industry experts are offering alternatives.

One such sterilizer in the United States engaged Anguil Environmental Systems and Montrose Environmental to see what could be done to retrofit an existing catalytic oxidizer with peak shaver that was originally designed for 99.9% removal or less than 1ppm per the previous regulations. Anguil, a pollution control system provider, and Montrose, a monitoring and testing supplier, met with the sterilizer to evaluate the system.

Using computational fluid dynamics (CFD) modeling to simulate flow and heat transfer within the induced draft system, engineers at Anguil recommended internal modifications be made within the oxidizer structure. Constructed of stainless steel, the internal modifications included multiple mixing vanes that provided sufficient blending to provide uniform flow and temperature distribution into the catalyst. Modifications were also made to the burner configuration to ensure better mixing, uniform temperature and flow distribution within the oxidizer.

During testing, Montrose simultaneously monitored the outlet of the peak shaver (catalytic oxidizer inlet) as well as the catalytic oxidizer outlet. Montrose utilized the Thermo Fisher Scientific™ Optically Enhanced MAX-IR™ OE-FTIR Gas Analyzer gas analyzer which allowed for measuring the outlet down to sub ppb levels while also measuring the inlet, where concentrations can be in the hundreds of ppm (without having to dilute the sample).

Through this industry collaboration, the sterilizer was able to meet and prove compliance with the new regulatory standards without purchasing a new abatement device or shutting down production.

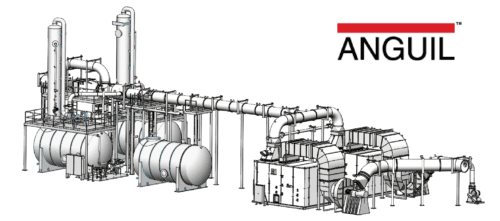

Anguil Environmental’s Proven EO Abatement Equipment

Catalytic Oxidizers are one of the most widely accepted control technologies available to control VOC emissions from the EO sterilization processes. Combining our flagship catalytic oxidizer with a peak shaver, Anguil’s EO abatement systems have helped clients achieve 99.99% destruction efficiency and limited EO concentrations to under one part-per-million by volume.

Anguil systems ensure zero leakage of EO from the oxidizer and safe operation by integrating the peak shaver, a packed tower counter-flow water scrubber, that absorbs ethylene oxide gas into the water by ensuring a high contact area between the gas and the water, preventing unsafe, high concentration conditions.

- Removal efficiencies of 99.99% to meet requirements in the US EPA NESHAP or as low as 0.5 mg/Nm³ to satisfy European regulations.

- Custom oxidation technologies to accommodate space restraints and site-specific requirements.

- The necessary experience to modify existing abatement systems to meet the new regulations.

- Local manufacturing and service capabilities throughout North and South America, Europe, and Asia for short equipment lead times and service response.

- Integrated Peak Shavers/Balancers with specialty mixers and detonation arrestors to ensure safe and effective operation.

- Natural gas, electric, propane, steam, or hydrogen heated oxidizers for carbon reduction initiatives.

- Over 25 years with EO abatement experience!

Montrose Environmental’s Proven Measurement Design

Montrose Environmental Group and Thermo Fisher Scientific have collaborated to provide an all-encompassing solution for organizations facing challenges in EO emissions monitoring, testing, and regulatory compliance. By integrating Montrose’s extensive project services expertise with Thermo Fisher’s cutting-edge Optically Enhanced MAX-IR™ OE-FTIR Gas Analyzer, clients gain access to a powerful combination that streamlines their efforts to meet stringent regulations.

The EMS-10™ Continuous Emissions Monitoring System (CEMS) is a fully automated 4-channel stack emission monitoring system which integrates the Thermo Fisher OE-FTIR analyzer. The EMS-10 system can quantify ethylene oxide down to a detection limit of under 1 ppb while maintaining short cycle times. The EMS-10 was designed to meet all the requirements found in PS-19 and operates as a continuous monitor with little-to-no user interaction.

For more information on the Montrose monitoring technology, visit this page.