Effective air pollution control is important in modern industrial facilities where the goals of ensuring regulatory compliance, minimizing environmental impacts, and maintaining a healthy bottom line, are all closely interlinked.

Regenerative thermal oxidizers—sometimes abbreviated to RTOs—can play a crucial role in eliminating hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) from industrial emissions efficiently and cost-effectively. So, what is a regenerative thermal oxidizer and how does it work?

What are Thermal Oxidizers?

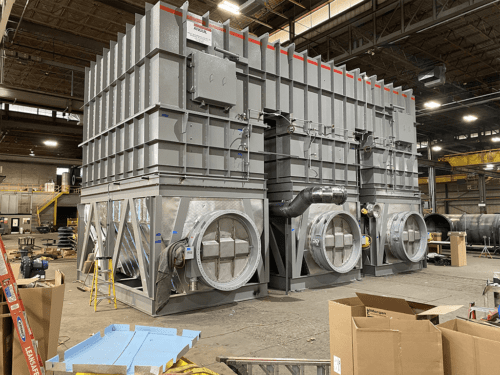

Anguil Three Chamber RTO in Fabrication

Thermal oxidizers are specialised combustion devices integrated into the ventilation of industrial processes that generate potentially harmful pollutants. Exhaust fumes travel through the oxidizer, which is heated to temperatures in the region of 1500°F, causing HAPs and VOCs to break down and form harmless compounds like carbon dioxide and water vapour. These can then be discharged into the atmosphere.

Although highly effective at destroying HAPs and VOCs, the problem with traditional thermal oxidizers is their extremely poor thermal efficiency. All heat energy employed in a conventional, direct-fired thermal oxidizer or vapor combustor is lost out the stack. An easy way to combat this is to employ a heat exchanger to recuperate thermal energy, but so-called thermal recuperative oxidizers (TROs) are limited to around 80% heat recovery rates and VOC destruction efficiencies of 99%.

There is a better solution that guarantees industrial compliance, reaches destruction efficiencies of 99+%, and offers thermal energy recovery efficiencies of up to 97%: regenerative thermal oxidizers.

Regenerative Thermal Oxidizer Design Principles

TROs tend to use standard metallic shell-and-tube heat exchanger systems, while regenerative thermal oxidizers use ceramic media beds with higher thermal efficiencies. In a dual-bed regenerative thermal oxidizer, incoming process emissions are drawn or pushed through the first ceramic bed via a high-pressure fan and pneumatic flow control valves.

The dirty stream exits the ceramic bed into the combustion chamber where burners rapidly break down contaminated compounds with a destruction efficiency greater than 99%. This purified stream is sent through a secondary ceramic bed where it relinquishes as much as 97% of its heat value into the exchange medium.

Regenerative thermal oxidizers reuse this recovered heat by periodically reversing the flow direction, courtesy of the pneumatic valves. The ceramic bed that recuperated heat from the purified stream is then used to preheat the incoming emissions, while clean, cool air is exhausted into the atmosphere.

This is not the only configuration, but it is the simplest one to gain a basic understanding of how regenerative thermal oxidizers work. Alternative systems include multi-chamber designs, although the same general principles apply.

Benefits of Regenerative Thermal Oxidizers

While some of the advantages of regenerative thermal oxidizers may be self-evident from their working principles, the extent of their value deserves further exploration. High-performance regenerative ceramic beds can enable fuel-free operation at very low VOC concentrations, as the cyclic flow reversal is so effective at reclaiming heat. Standard regenerative thermal oxidizers subsequently deliver extremely low operating costs for high air flow fume streams with low VOC concentrations.

Regenerative Thermal Oxidizers from Anguil

Anguil is one of the leading regenerative thermal oxidizer manufacturers worldwide. Our solutions are tried-and-trusted by business units across the global industrial landscape, because we understand the need to achieve multiple goals in tandem when it comes to selecting new air pollution control systems. Our cutting-edge regenerative thermal oxidizers guarantee compliance with the relevant industrial regulations, while ensuring the maximum process efficiency and system lifetime expectancy.

Want to learn more? Head over to our contact page to get in touch with an applications specialist or submit your project specifications directly and we will get back to you as soon as possible with equipment sizing, estimated operating costs, and delivery times.

3,155 Comments

JasonJic

You can find a comprehensive collection of trusted medicines for various needs.

Our platform provides fast and safe shipping to your location.

Every item is supplied by trusted pharmaceutical companies to ensure authenticity and compliance.

You can explore our online store and make a purchase in minutes.

If you have questions, Our support team are here to help 24/7.

Prioritize your well-being with our trusted online pharmacy!

https://pbase.com/silagra/image/174947419

play casino

Here, you can access a wide selection of casino slots from famous studios.

Players can enjoy retro-style games as well as modern video slots with stunning graphics and exciting features.

If you’re just starting out or a seasoned gamer, there’s always a slot to match your mood.

money casino

All slot machines are ready to play 24/7 and optimized for PCs and tablets alike.

You don’t need to install anything, so you can get started without hassle.

Site navigation is easy to use, making it convenient to browse the collection.

Sign up today, and enjoy the thrill of casino games!

bs2best.markets

Площадка BlackSprut — это одна из самых известных онлайн-площадок в теневом интернете, открывающая разные функции для пользователей.

В этом пространстве предусмотрена простая структура, а структура меню простой и интуитивный.

Пользователи выделяют стабильность работы и активное сообщество.

bs2best

BlackSprut ориентирован на удобство и безопасность при использовании.

Кому интересны альтернативные цифровые пространства, этот проект станет удобной точкой старта.

Перед использованием лучше ознакомиться с основы сетевой безопасности.

MichealReure

This online service provides various medications for home delivery.

Users can securely access treatments from anywhere.

Our catalog includes standard medications and targeted therapies.

The full range is supplied through verified providers.

https://www.hr.com/en/app/calendar/event/suhagra-a-comprehensive-guide-to-this-ed-medicatio_ltx0i2oe.html

We ensure quality and care, with encrypted transactions and prompt delivery.

Whether you’re filling a prescription, you’ll find safe products here.

Start your order today and enjoy reliable online pharmacy service.

Кримінальна робота

На этом сайте предлагает поиска работы в разных регионах.

Пользователям доступны множество позиций от проверенных работодателей.

На платформе появляются предложения в разнообразных нишах.

Частичная занятость — выбор за вами.

https://my-articles-online.com/

Сервис простой и адаптирован на любой уровень опыта.

Регистрация производится в несколько кликов.

Готовы к новым возможностям? — начните прямо сейчас.

play casino

This website, you can access lots of casino slots from famous studios.

Visitors can try out classic slots as well as new-generation slots with vivid animation and bonus rounds.

Whether you’re a beginner or a seasoned gamer, there’s something for everyone.

money casino

The games are ready to play 24/7 and compatible with PCs and mobile devices alike.

You don’t need to install anything, so you can get started without hassle.

Platform layout is easy to use, making it convenient to find your favorite slot.

Register now, and enjoy the excitement of spinning reels!

money casino

On this platform, you can access a great variety of slot machines from leading developers.

Visitors can try out retro-style games as well as new-generation slots with stunning graphics and bonus rounds.

Even if you’re new or an experienced player, there’s a game that fits your style.

casino

The games are ready to play 24/7 and compatible with laptops and smartphones alike.

You don’t need to install anything, so you can start playing instantly.

Site navigation is user-friendly, making it simple to find your favorite slot.

Sign up today, and dive into the excitement of spinning reels!

canada pharmaceuticals

I pay a quick visit each day some web pages and blogs to read articles, however this weblog presents quality based writing.

DustinNah

Traditional timepieces will consistently be fashionable.

They represent engineering excellence and showcase a human touch that smartwatches simply cannot match.

Each piece is powered by complex gears, making it both useful and artistic.

Watch enthusiasts value the hand-assembled parts.

https://trackrecord.id/read-blog/10732

Wearing a mechanical watch is not just about telling time, but about celebrating tradition.

Their styles are timeless, often passed from one owner to another.

All in all, mechanical watches will remain icons.

casino games

On this platform, you can discover a great variety of online slots from famous studios.

Players can enjoy traditional machines as well as modern video slots with high-quality visuals and exciting features.

Even if you’re new or an experienced player, there’s something for everyone.

money casino

All slot machines are available anytime and designed for laptops and tablets alike.

No download is required, so you can get started without hassle.

The interface is user-friendly, making it simple to explore new games.

Join the fun, and dive into the world of online slots!

Michaeldat

It’s alarming to realize that over 60% of medication users commit preventable medication errors stemming from poor understanding?

Your wellbeing requires constant attention. Each pharmaceutical choice you implement directly impacts your body’s functionality. Staying educated about medical treatments should be mandatory for optimal health outcomes.

Your health isn’t just about following prescriptions. Each drug interacts with your body’s chemistry in potentially dangerous ways.

Never ignore these essential facts:

1. Mixing certain drugs can cause fatal reactions

2. Over-the-counter pain relievers have serious risks

3. Altering dosages undermines therapy

To avoid risks, always:

✓ Research combinations via medical databases

✓ Read instructions in detail when starting any medication

✓ Consult your doctor about potential side effects

___________________________________

For reliable drug information, visit:

https://www.provenexpert.com/patellofemoral-pain-syndrome/

JamesFurce

The digital drugstore offers an extensive variety of health products with competitive pricing.

You can find all types of remedies for all health requirements.

We work hard to offer high-quality products while saving you money.

Speedy and secure shipping provides that your purchase arrives on time.

Enjoy the ease of ordering medications online on our platform.

kamagra jelly 100mg

Davidglank

This service allows adventure rides across the island.

Visitors can easily reserve a buggy for travel.

If you’re looking to travel around hidden beaches, a buggy is the perfect way to do it.

https://pixabay.com/users/buggycrete-49906515/

The fleet are safe and clean and offered with flexible plans.

Through our service is fast and comes with affordable prices.

Start your journey and enjoy Crete like never before.

alarm-radio-clocks.com

This section showcases CD/radio/clock combos from reputable makers.

You can find top-loading CD players with PLL tuner and two alarm settings.

Many models include auxiliary inputs, USB charging, and battery backup.

Our range extends from affordable clocks to high-end designs.

best clock radio cd player

All devices provide sleep timers, auto-off timers, and digital displays.

Shop the collection through Amazon links with free shipping.

Find the perfect clock-radio-CD setup for bedroom everyday enjoyment.

casino slots

This website, you can discover a wide selection of online slots from leading developers.

Players can enjoy traditional machines as well as new-generation slots with stunning graphics and bonus rounds.

If you’re just starting out or an experienced player, there’s a game that fits your style.

play casino

Each title are instantly accessible round the clock and optimized for PCs and mobile devices alike.

All games run in your browser, so you can start playing instantly.

Platform layout is intuitive, making it simple to find your favorite slot.

Join the fun, and discover the thrill of casino games!

каско

Приобретение страховки во время путешествия — это обязательное условие для финансовой защиты путешественника.

Документ включает медицинские услуги в случае несчастного случая за границей.

Также, сертификат может обеспечивать оплату на медицинскую эвакуацию.

осаго рассчитать

Некоторые государства предусматривают предоставление документа для получения визы.

Без страховки обращение к врачу могут быть финансово обременительными.

Оформление полиса заблаговременно

hire an assassin

This website allows you to connect with workers for temporary dangerous projects.

Clients may quickly request services for specific operations.

All contractors have expertise in dealing with intense jobs.

killer for hire

Our platform guarantees safe interactions between requesters and workers.

Whether you need urgent assistance, our service is here for you.

Post your request and connect with the right person today!

assumi assassino

Questo sito consente l’assunzione di persone per lavori pericolosi.

Gli interessati possono trovare professionisti specializzati per lavori una tantum.

Ogni candidato vengono scelti con attenzione.

assumere un killer

Utilizzando il servizio è possibile ottenere informazioni dettagliate prima di assumere.

La professionalità è un nostro impegno.

Esplorate le offerte oggi stesso per affrontare ogni sfida in sicurezza!

1xbet-official.live

В этом разделе вы можете обнаружить рабочую копию сайта 1хБет без проблем.

Постоянно обновляем доступы, чтобы облегчить беспрепятственный доступ к порталу.

Переходя через зеркало, вы сможете делать ставки без рисков.

1хбет зеркало

Данный портал поможет вам без труда открыть актуальный адрес 1хбет.

Мы заботимся, чтобы каждый пользователь был в состоянии работать без перебоев.

Следите за актуальной информацией, чтобы всегда оставаться в игре с 1 икс бет!

bottega veneta очки

Наша платформа — подтверждённый цифровой магазин Bottega Венета с доставкой по всей России.

На нашем сайте вы можете приобрести эксклюзивные вещи Боттега Венета напрямую.

Каждая покупка подтверждаются оригинальными документами от бренда.

bottega-official.ru

Доставка осуществляется быстро в по всей территории России.

Бутик онлайн предлагает разные варианты платежей и комфортные условия возврата.

Выбирайте официальном сайте Боттега Венета, чтобы быть уверенным в качестве!

为了钱而下令谋杀

在本站,您可以聘请专门从事临时的危险工作的执行者。

我们提供大量训练有素的工作人员供您选择。

无论面对何种复杂情况,您都可以方便找到专业的助手。

如何在网上下令谋杀

所有作业人员均经过筛选,确保您的隐私。

平台注重专业性,让您的个别项目更加安心。

如果您需要服务详情,请直接留言!

JosephFaire

Through this platform, you can browse top CS:GO gaming sites.

We feature a diverse lineup of gaming platforms centered around CS:GO players.

Every website is thoroughly reviewed to provide safety.

crash csgo

Whether you’re an experienced gamer, you’ll easily choose a platform that fits your style.

Our goal is to guide you to enjoy proven CS:GO betting sites.

Explore our list at your convenience and enhance your CS:GO betting experience!

Geraldduels

?Hola cazadores de suerte

Los jugadores espaГ±oles pueden acceder a 12e de dinero gratis sin necesidad de depГіsito. [url=п»їhttps://100girosgratissindepositoespana.guru/]giros gratis espaГ±a[/url] Solo crea tu cuenta y empieza a girar.

Con 100 euros gratis sin deposito, puedes jugar durante horas sin gastar. Perfecto para explorar mГєltiples juegos. ВЎDiviГ©rtete sin riesgo!

Reclama cГіdigos tiradas gratis casino sin riesgos – 100girosgratissindepositoespana.guru.

?Que tengas excelentes juegos !

hitman-assassin-killer.com

Our service lets you get in touch with specialists for temporary hazardous jobs.

Visitors are able to quickly schedule help for unique situations.

All listed individuals are experienced in executing complex jobs.

killer for hire

The website ensures safe communication between clients and workers.

When you need a quick solution, our service is the right choice.

Post your request and match with the right person today!

ordina omicidio l'uccisione

La nostra piattaforma consente l’ingaggio di operatori per lavori pericolosi.

I clienti possono selezionare candidati qualificati per incarichi occasionali.

Le persone disponibili sono selezionati con severi controlli.

sonsofanarchy-italia.com

Attraverso il portale è possibile consultare disponibilità prima della scelta.

La sicurezza rimane la nostra priorità.

Iniziate la ricerca oggi stesso per trovare il supporto necessario!

hire a killer

Seeking to hire reliable professionals available to tackle one-time dangerous projects.

Need someone for a hazardous assignment? Find certified experts on our platform for urgent dangerous work.

hitman for hire

Our platform links employers with licensed professionals prepared to accept hazardous temporary gigs.

Hire pre-screened freelancers to perform dangerous jobs safely. Perfect when you need emergency situations requiring specialized expertise.

casino

This website, you can discover a wide selection of casino slots from famous studios.

Users can try out traditional machines as well as modern video slots with high-quality visuals and exciting features.

If you’re just starting out or an experienced player, there’s always a slot to match your mood.

play casino

All slot machines are available round the clock and compatible with PCs and mobile devices alike.

All games run in your browser, so you can jump into the action right away.

The interface is easy to use, making it simple to explore new games.

Register now, and enjoy the thrill of casino games!

how to kill yourself

People consider ending their life for a variety of reasons, often stemming from deep emotional pain.

The belief that things won’t improve might overpower their motivation to go on. In many cases, loneliness contributes heavily in pushing someone toward such thoughts.

Conditions like depression or anxiety can cloud judgment, causing people to recognize options beyond their current state.

how to commit suicide

Life stressors could lead a person toward this extreme step.

Inadequate support systems might result in a sense of no escape. Keep in mind that reaching out is crucial.

色情网站

访问者请注意,这是一个成人网站。

进入前请确认您已年满成年年龄,并同意接受相关条款。

本网站包含成人向资源,请自行判断是否适合进入。 色情网站。

若您未满18岁,请立即退出页面。

我们致力于提供合法合规的网络体验。

order a killer

Looking for someone to handle a one-time hazardous task?

Our platform specializes in connecting customers with contractors who are ready to tackle high-stakes jobs.

Whether you’re handling emergency repairs, unsafe cleanups, or complex installations, you’re at the right place.

All available professional is vetted and certified to guarantee your security.

hire an assassin

This service offer clear pricing, comprehensive profiles, and safe payment methods.

Regardless of how challenging the scenario, our network has the expertise to get it done.

Begin your search today and find the perfect candidate for your needs.

how to become a hacker

You can find here valuable information about how to become a IT infiltrator.

Details are given in a unambiguous and clear-cut manner.

It helps master several procedures for penetrating networks.

Furthermore, there are real-life cases that demonstrate how to perform these competencies.

how to become a hacker

Whole material is continuously improved to remain relevant to the recent advancements in cybersecurity.

Notable priority is given to operational employment of the absorbed know-how.

Take into account that every action should be applied lawfully and for educational purposes only.

WileyMed

Our website is possible to discover useful discount codes for 1xBet.

Such codes allow to acquire supplementary benefits when placing bets on the platform.

Each provided promo deals are always up-to-date to maintain their usability.

By applying these offers there is an opportunity to improve your potential winnings on 1xBet.

https://pyarishayari.in/pgs/issledovanievliyani.html

Plus, full explanations on how to use promo deals are offered for ease of use.

Remember that specific offers may have time limits, so examine rules before applying.

Billydib

¡Hola buscadores de emociones !

En 25girosgratissindeposito.xyz encontrarГЎs promociones actualizadas. Consigue tus giros gratis por registro sin depГіsito. Ideal para jugadores nuevos.

Los bonos sin depГіsito como 25 giros gratis sin depГіsito son perfectos para nuevos jugadores.

¡Que tengas magníficas victorias memorables !

Stevensed

This site you can obtain limited special offers for one of the leading betting services.

The selection of promotional offers is continuously improved to ensure that you always have means to utilize the up-to-date offers.

Using these promo codes, you can save a lot on your bets and amplify your potential of winning.

All special offers are attentively reviewed for authenticity and efficiency before being published.

https://vivum.net/wp-content/articles/345stoit_li_pokupaty_novyy_avtomobily_mify_i_realynosty.html

Moreover, we supply full directions on how to implement each rewarding chance to optimize your advantages.

Take into account that some arrangements may have unique stipulations or time limitations, so it’s vital to read carefully all the data before applying them.

threesome photos

Welcome to our platform, where you can discover special materials designed exclusively for adults.

The entire collection available here is suitable only for individuals who are over 18.

Ensure that you are eligible before continuing.

asian videos

Experience a special selection of age-restricted content, and dive in today!

DavidTow

¡Hola, aventureros de las apuestas !

[url=https://www.youtube.com/watch?v=DvFWSMyjao4]machance casino 10€[/url]

ObtГ©n 10 euros gratis sin depГіsito casino ozwin y disfruta de una experiencia de juego Гєnica. Es una excelente manera de probar nuevos juegos y estrategias. RegГstrate y comienza a ganar sin invertir tu propio dinero.

Bono instantГЎneo: 10 euros por registrarte – https://www.youtube.com/watch?v=DvFWSMyjao4&list=PLX0Xt4gdc3aLv2xrbmSCzHqZw12bA17Br

¡Que tengas excelentes triunfos !

MichealReure

This online service features various prescription drugs for easy access.

Anyone can securely get essential medicines from your device.

Our product list includes everyday drugs and specialty items.

Each item is sourced from reliable providers.

cenforce 200 sildenafil

We ensure customer safety, with private checkout and timely service.

Whether you’re filling a prescription, you’ll find what you need here.

Visit the store today and experience stress-free access to medicine.

WileyMed

1XBet represents a premier online betting provider.

With a wide range of sports, 1xBet serves countless users worldwide.

The One X Bet mobile app crafted intended for Android devices as well as iOS users.

https://www.bnbaccess.eu/art/obespechivayut_li_moskitnye_setki_effektivnuyu_zaschitu_ot_nasekomyh.html

It’s possible to download the application via the official website as well as Google Play Store for Android users.

For iOS users, the application can be installed via the App Store with ease.

MichealReure

The site makes available various pharmaceuticals for online purchase.

You can quickly access treatments without leaving home.

Our product list includes everyday solutions and targeted therapies.

Everything is acquired via verified suppliers.

is fildena safe

We maintain quality and care, with secure payments and prompt delivery.

Whether you’re looking for daily supplements, you’ll find affordable choices here.

Start your order today and experience stress-free online pharmacy service.

1xbet promo code for registration

1XBet Promo Code – Vip Bonus up to $130

Use the 1XBet promotional code: 1xbro200 when registering on the app to unlock special perks given by One X Bet to receive €130 maximum of a full hundred percent, for placing bets plus a €1950 including 150 free spins. Open the app then continue with the registration procedure.

This 1xBet promotional code: 1XBRO200 gives an amazing sign-up bonus to new players — full one hundred percent maximum of $130 once you register. Bonus codes are the key to unlocking extra benefits, plus One X Bet’s promotional codes are no exception. When applying this code, bettors may benefit of various offers throughout their journey of their betting experience. Although you aren’t entitled to the starter reward, 1XBet India guarantees its devoted players are rewarded through regular bonuses. Check the Promotions section on the site regularly to remain aware on the latest offers meant for loyal customers.

1xbet promo code free bet

Which One X Bet bonus code is currently active right now?

The bonus code for 1xBet is 1xbro200, which allows first-time users joining the betting service to gain a bonus worth $130. For gaining exclusive bonuses for casino and wagering, please input this special code for 1XBET in the registration form. To take advantage of this offer, potential customers must input the bonus code Code 1xbet while signing up procedure for getting a full hundred percent extra for their first payment.

bbc videos

On this site, access an extensive collection adult videos.

Every video is carefully curated providing maximum satisfaction for users.

In need of certain themes or just browsing, this site has something for everyone.

bbc videos

New videos uploaded frequently, ensuring the library always growing.

Viewing of all materials is restricted to users of legal age, maintaining standards with applicable laws.

Stay tuned and fresh uploads, as the platform expands its library daily.

Edwardclork

1xBet Promotional Code – Special Bonus up to €130

Use the 1XBet promo code: 1xbro200 when registering via the application to unlock the benefits offered by 1XBet and get welcome bonus maximum of a full hundred percent, for placing bets and a $1950 with free spin package. Start the app followed by proceeding through the sign-up procedure.

This 1xBet promo code: Code 1XBRO200 offers a fantastic welcome bonus to new players — a complete hundred percent up to $130 during sign-up. Promotional codes serve as the key to obtaining rewards, plus 1XBet’s promotional codes are no exception. By using the code, bettors may benefit from multiple deals throughout their journey within their betting activity. Even if you don’t qualify for the welcome bonus, 1xBet India guarantees its devoted players receive gifts with frequent promotions. Look at the Deals tab on the site regularly to stay updated about current deals designed for loyal customers.

https://extraordinarz.com/profile.php?from=space&action=view&username=geri-hardey-431315&op=userinfo&mod=space

What 1XBet bonus code is presently available today?

The promo code relevant to 1xBet equals Code 1XBRO200, which allows novice players signing up with the bookmaker to gain a reward of $130. To access special rewards pertaining to gaming and wagering, please input the promotional code concerning 1XBET in the registration form. To take advantage of this offer, prospective users should enter the promotional code 1XBET at the time of registering process to receive a full hundred percent extra on their initial deposit.

Jamesbar

Здесь доступны последние коды Melbet-промо.

Используйте их во время создания аккаунта в системе чтобы получить полный бонус за первое пополнение.

Также, доступны коды в рамках действующих программ для лояльных участников.

мелбет промокод

Обновляйте информацию в разделе промокодов, и будьте в курсе выгодные предложения от Melbet.

Каждый бонус проверяется на актуальность, поэтому вы можете быть уверены при использовании.

Maydat

Свадебные новинки будущего сезона в наши дни начинают формироваться.

На первом месте — естественность, что выражается дышащих текстурах и простых силуэтах.

Особую популярность завоевывают платья с открытыми плечами, подчеркивающие легкость.

http://xn--12cg0dgd0cgkso9a9eg1b0dvhwf.com/index.php?topic=57119.new#new

Цветовая палитра расширяется, предлагая мягкие оттенки, как например: мята.

Внимание к мелочам остается важным, прежде всего кружева и ручная работа.

Новым веянием выступают комбинированные образы, к примеру: пышная юбка с корсетом.

Ronalddor

¡Hola cazadores de adrenalina !

Casinosinkyc se ha posicionado como una alternativa confiable para jugar sin restricciones. Te permite registrarte sin enviar ni un solo documento. Todo es mГЎs directo.

Las plataformas sin registro ofrecen chat en vivo con crupieres. MГЎs interacciГіn. [url=https://casinosinkyc.guru/#]https://casinosinkyc.guru/[/url]

casinos sin verificaciГіn casinos sin kyc en un clic – п»їhttps://casinosinkyc.guru/

¡Que tengas maravillosas lanzamientos afortunados !

1xbet free promo code india

1XBet Promotional Code – Exclusive Bonus maximum of $130

Enter the One X Bet promo code: 1xbro200 during sign-up in the App to unlock the benefits offered by 1XBet and get $130 as much as a full hundred percent, for sports betting along with a 1950 Euros including 150 free spins. Launch the app followed by proceeding by completing the registration process.

The 1xBet bonus code: 1XBRO200 gives a fantastic welcome bonus to new players — full one hundred percent as much as $130 upon registration. Bonus codes serve as the key to unlocking rewards, also 1XBet’s bonus codes aren’t different. When applying this code, users can take advantage from multiple deals at different stages of their betting experience. Although you don’t qualify for the welcome bonus, One X Bet India guarantees its devoted players receive gifts with frequent promotions. Look at the Deals tab on the site regularly to stay updated about current deals meant for current users.

1xbet free bet promo code india

Which 1XBet bonus code is presently available at this moment?

The bonus code for One X Bet is 1XBRO200, which allows new customers signing up with the bookmaker to gain a bonus amounting to $130. To access exclusive bonuses for casino and sports betting, make sure to type our bonus code related to 1XBET in the registration form. To take advantage of this offer, future players should enter the bonus code 1xbet at the time of registering step to receive a 100% bonus applied to the opening contribution.

1xbet

On this site, find a variety of online casinos.

Interested in traditional options latest releases, there’s a choice for any taste.

The listed platforms checked thoroughly to ensure security, so you can play with confidence.

vavada

What’s more, the site offers exclusive bonuses plus incentives to welcome beginners including long-term users.

With easy navigation, finding your favorite casino happens in no time, making it convenient.

Keep informed about the latest additions by visiting frequently, since new casinos come on board often.

Ernesto

Ernesto.it rappresenta una soluzione affidabile e innovativa per la gestione dei sistemi di ossidazione termica rigenerativa. La sua esperienza e competenza nel settore garantiscono un supporto di alta qualità, contribuendo a ottimizzare l’efficienza degli impianti e a ridurre l’impatto ambientale. Consiglio vivamente Ernesto.it a tutte le aziende che desiderano implementare tecnologie sostenibili e all’avanguardia come i Thermal Oxidizers. Sono estremamente soddisfatto dei servizi forniti e della professionalità dimostrata.

Angeldrief

Create vivid images with Promptchan AI — a powerful neural network for generating art based on text description. Support for SFW and NSFW modes, style customization, quick creation of visual content.

Donaldcet

Портал о недвижимости https://akadem-ekb.ru всё, что нужно знать о продаже, покупке и аренде жилья. Актуальные объявления, обзоры новостроек, советы экспертов, юридическая информация, ипотека, инвестиции. Помогаем выбрать квартиру или дом в любом городе.

EdwardRed

Срочный выкуп квартир https://proday-kvarti.ru за сутки — решим ваш жилищный или финансовый вопрос быстро. Гарантия законности сделки, юридическое сопровождение, помощь на всех этапах. Оценка — бесплатно, оформление — за наш счёт. Обращайтесь — мы всегда на связи и готовы выкупить квартиру.

WallaceStoop

Недвижимость в Болгарии у моря https://byalahome.ru квартиры, дома, апартаменты в курортных городах. Продажа от застройщиков и собственников. Юридическое сопровождение, помощь в оформлении ВНЖ, консультации по инвестициям.

casino

Here, you can access lots of online slots from leading developers.

Players can try out traditional machines as well as feature-packed games with stunning graphics and bonus rounds.

Even if you’re new or an experienced player, there’s something for everyone.

slots

Each title are available 24/7 and designed for laptops and mobile devices alike.

No download is required, so you can start playing instantly.

Platform layout is intuitive, making it simple to explore new games.

Join the fun, and enjoy the thrill of casino games!

Erickvus

Mechanical watches remain the epitome of timeless elegance.

In a world full of smart gadgets, they undoubtedly hold their style.

Built with precision and mastery, these timepieces embody true horological excellence.

Unlike fleeting trends, fine mechanical watches do not go out of fashion.

https://uconnect.ae/read-blog/115443

They stand for heritage, legacy, and enduring quality.

Whether used daily or saved for special occasions, they forever remain in style.

sajt-kopirajtera

Ищете копирайтера? https://sajt-kopirajtera.ru Пишу тексты, которые продают, вовлекают и объясняют. Создам контент для сайта, блога, рекламы, каталога. Работаю с ТЗ, разбираюсь в SEO, адаптирую стиль под задачу. Чистота, смысл и результат — мои приоритеты. Закажите текст, который работает на вас.

topdommsk

Архитектурные решения проекты домов под ваши желания и участок. Создадим проект с нуля: планировка, фасад, инженерия, визуализация. Вы получите эксклюзивный дом, адаптированный под ваш образ жизни. Работаем точно, качественно и с любовью к деталям.

EdgarCap

Headless automation tools like https://surfsky.io can help reduce detection risks by using real browser environments and proper fingerprinting. This can be critical when working with anti-bot systems or scraping complex websites.

Josephglono

Headless automation tools like https://surfsky.io can help reduce detection risks by using real browser environments and proper fingerprinting. This can be critical when working with anti-bot systems or scraping complex websites.

Adrianmax

Туристический портал https://prostokarta.com.ua для путешественников: маршруты, достопримечательности, советы, бронирование туров и жилья, билеты, гайды по странам и городам. Планируйте отпуск легко — всё о путешествиях в одном месте.

WillyEpilA

Фитнес-портал https://sportinvent.com.ua ваш помощник в достижении спортивных целей. Тренировки дома и в зале, план питания, расчёт калорий, советы тренеров и диетологов. Подходит для начинающих и профессионалов. Всё о фитнесе — в одном месте и с реальной пользой для здоровья.

Jameslat

Инновации, технологии, наука https://technocom.dp.ua на одном портале. Читайте о передовых решениях, новых продуктах, цифровой трансформации, робототехнике, стартапах и будущем IT. Всё самое важное и интересное из мира высоких технологий в одном месте — просто, понятно, актуально.

MerleJal

Всё о мобильной технике https://webstore.com.ua и технологиях: смартфоны, планшеты, гаджеты, новинки рынка, обзоры, сравнения, тесты, советы по выбору и настройке. Следите за тенденциями, обновлениями ОС и инновациями в мире мобильных устройств.

Philliparori

YouTube Promotion buy youtube views for your videos and increase reach. Real views from a live audience, quick launch, flexible packages. Ideal for new channels and content promotion. We help develop YouTube safely and effectively.

Dennisgox

Натяжные потолки под ключ https://medium.com/@ksv.viet87/натяжные-потолки-мифы-о-вреде-и-экспертное-мнение-от-nova-28054185c2fd установка любых видов: матовые, глянцевые, сатиновые, многоуровневые, с фотопечатью и подсветкой. Широкий выбор фактур и цветов, замер бесплатно, монтаж за 1 день. Качественные материалы, гарантия и выгодные цены от производителя.

Joshuanen

Автомобильный портал https://autodream.com.ua для автолюбителей и профессионалов: новости автоиндустрии, обзоры, тест-драйвы, сравнение моделей, советы по уходу и эксплуатации. Каталог авто, форум, рейтинги, автоновости. Всё об автомобилях — в одном месте, доступно и интересно.

Hectortig

Портал про авто https://livecage.com.ua всё для автолюбителей: обзоры машин, тест-драйвы, новости автопрома, советы по ремонту и обслуживанию. Выбор авто, сравнение моделей, тюнинг, страховка, ПДД. Актуально, понятно и полезно. Будьте в курсе всего, что связано с автомобилями!

JosephBum

Современный женский портал https://beautyrecipes.kyiv.ua стиль жизни, мода, уход за собой, семья, дети, кулинария, карьера и вдохновение. Полезные советы, тесты, статьи и истории. Откровенно, интересно, по-настоящему. Всё, что важно и близко каждой женщине — в одном месте.

Michaeltak

На женском портале https://happytime.in.ua статьи для души и тела: секреты красоты, женское здоровье, любовь и семья, рецепты, карьерные идеи, вдохновение. Место, где можно быть собой, делиться опытом и черпать силу в заботе о себе.

Jeffreysah

Добро пожаловать на женский портал https://lidia.kr.ua ваш гид по миру красоты, стиля и внутренней гармонии. Читайте про отношения, карьеру, воспитание детей, женское здоровье, эмоции и моду. Будьте вдохновлены лучшей версией себя каждый день вместе с нами.

Jasonmog

Ты можешь всё https://love.zt.ua а мы подскажем, как. Женский портал о саморазвитии, личной эффективности, карьере, балансе между семьёй и амбициями. Здесь — опыт успешных женщин, практичные советы и реальные инструменты для роста.

Nelsonvow

Женский онлайн-журнал https://loveliness.kyiv.ua о стиле, красоте, вдохновении и трендах. Интервью, мода, бьюти-обзоры, психология, любовь и карьера. Будь в курсе главного, читай мнения экспертов, следи за трендами и открывай новые грани себя каждый день.

Matthewtic

Онлайн-журнал для женщин https://mirwoman.kyiv.ua которые ищут не только советы, но и тепло. Личные истории, женское здоровье, психология, уютный дом, забота о себе, рецепты, отношения. Без давления, без шаблонов. Просто жизнь такой, какая она есть.

Ronniedug

Портал для женщин https://oa.rv.ua всё, что важно: красота, здоровье, семья, карьера, мода, отношения, рецепты и саморазвитие. Полезные статьи, советы, тесты и вдохновение каждый день. Онлайн-пространство, где каждая найдёт ответы и поддержку.

DavidVak

Современный женский портал https://womanonline.kyiv.ua с актуальными темами: тренды, уход, макияж, фитнес, fashion, интервью, советы стилистов. Следи за модой, вдохновляйся образами, узнай, как подчеркнуть свою индивидуальность.

Raymondnus

Today

users choose

internet shopping. Even household items

to beauty products, nearly everything

may be purchased from home.

The rise of digital shopping led to

modern buying behavior.

https://uberant.com/article/2054165-new-balance-1500-a-timeless-classic-in-the-world-of-running-sneakers/

1win

On this site, find a wide range of online casinos.

Interested in classic games latest releases, you’ll find an option to suit all preferences.

Every casino included are verified to ensure security, enabling gamers to bet peace of mind.

1win

Moreover, the platform offers exclusive bonuses and deals for new players including long-term users.

Thanks to user-friendly browsing, discovering a suitable site takes just moments, saving you time.

Stay updated on recent updates through regular check-ins, since new casinos come on board often.

HarolddranO

Сайт для женщин https://womenclub.kr.ua всё, что волнует и вдохновляет: мода, красота, здоровье, отношения, дети, психология и карьера. Практичные советы, интересные статьи, вдохновение каждый день. Онлайн-пространство, созданное с заботой о вас и вашем настроении.

FrankSix

Медицинский портал https://lpl.org.ua с проверенной информацией от врачей: симптомы, заболевания, лечение, диагностика, препараты, ЗОЖ. Консультации специалистов, статьи, тесты и новости медицины. Только достоверные данные — без паники и домыслов. Здоровье начинается с знаний.

Raymondcrync

Надёжный медицинский портал https://una-unso.cv.ua созданный для вашего здоровья и спокойствия. Статьи о заболеваниях, советы по лечению и образу жизни, подбор клиник и врачей. Понятный язык, актуальная информация, забота о вашем самочувствии — каждый день.

Randallfliew

Чайная энциклопедия https://etea.com.ua всё о мире чая: сорта, происхождение, свойства, способы заваривания, чайные традиции разных стран. Узнайте, как выбрать качественный чай, в чём его польза и как раскрывается вкус в каждой чашке. Для ценителей и новичков.

Georgecat

Кулинарный портал https://mallinaproject.com.ua тысячи рецептов, пошаговые инструкции, фото, видео, удобный поиск по ингредиентам. Готовьте вкусно и разнообразно: от завтраков до десертов, от традиционной кухни до кулинарных трендов. Быстро, доступно, понятно!

Ricardogaf

Современный мужской портал https://smart4business.net о жизни, успехе и саморазвитии. Личный рост, инвестиции, бизнес, стиль, технологии, мотивация. Разбираем стратегии, делимся опытом, вдохновляем на движение вперёд. Для тех, кто выбирает силу, разум и результат.

Brianfaife

Все новинки технологий https://axioma-techno.com.ua в одном месте: презентации, релизы, выставки, обзоры и утечки. Следим за рынком гаджетов, IT, авто, AR/VR, умного дома. Обновляем ежедневно. Не пропустите главные технологические события и открытия.

Lesterfok

Новинки технологий https://dumka.pl.ua портал о том, как научные открытия становятся частью повседневности. Искусственный интеллект, нанотехнологии, биоинженерия, 3D-печать, цифровизация. Простым языком о сложном — для тех, кто любит знать, как работает мир.

Ralphdot

Актуальные новости https://polonina.com.ua каждый день — политика, экономика, культура, спорт, технологии, происшествия. Надёжный источник информации без лишнего. Следите за событиями в России и мире, получайте факты, мнения и обзоры.

DavidTog

Автомобильный сайт https://kolesnitsa.com.ua для души: редкие модели, автофан, необычные тесты, автоистории, подборки и юмор. Лёгкий и увлекательный контент, который приятно читать. Здесь не только про машины — здесь про стиль жизни на колёсах.

RobertoScact

Следите за трендами автопрома https://viewport.com.ua вместе с нами! На авто портале — новинки, презентации, обзоры, технологии, электромобили, автосалоны и экспертные мнения. Ежедневные обновления, честный взгляд на рынок, без лишнего шума и рекламы.

PhillipPause

Полезные статьи и советы https://britishschool.kiev.ua на каждый день: здоровье, финансы, дом, отношения, саморазвитие, технологии и лайфхаки. Читайте, применяйте, делитесь — всё, что помогает жить проще, осознаннее и эффективнее. Достоверная информация и реальная польза.

Ramirojex

Сайт для женщин https://funtura.com.ua всё, что интересно каждый день: бьюти-советы, рецепты, отношения, дети, стиль, покупки, лайфхаки и настроение. Яркие статьи, тесты и вдохновение. Просто, легко, по-женски.

MichaelHix

Это не просто сайт для женщин https://godwood.com.ua это пространство, где вас слышат. Здесь — забота, поддержка, советы по жизни, отношениям, здоровью, семье и внутреннему балансу. Никакой критики, только доброта и уверенность: всё будет хорошо, и вы не одна.

Donaldboize

Информационно-познавательный https://golosiyiv.kiev.ua портал для мужчин и женщин: полезные статьи, советы, обзоры, лайфхаки, здоровье, психология, стиль, семья и финансы. Всё, что важно знать для жизни, развития и комфорта. Читайте, развивайтесь, вдохновляйтесь вместе с нами.

DustinGax

черный натяжной потолок установлен натяжной потолок

RaymondOraps

Женский онлайн-журнал https://gorod-lubvi.com.ua о красоте, стиле и уходе. Советы визажистов, подбор образов, секреты молодости, модные тренды. Всё, чтобы чувствовать себя уверенно и выглядеть на миллион. Будь в курсе, вдохновляйся и подбирай стиль по душе.

Gregorytweld

Сильная, умная, стильная https://lugor.org.ua вот для кого наш женский онлайн-журнал. Темы: мода, карьера, дети, отношения, дом, здоровье. Разговор о реальной жизни: без глянца, но со вкусом.

WilliamSpoog

Женский онлайн-журнал https://inclub.lg.ua о силе выбора. Карьера, финансы, тайм-менеджмент, уверенность, стиль и баланс. Для женщин, которые двигаются вперёд, строят, влияют, мечтают. Говорим по делу — без стереотипов и с уважением к вашему пути.

Rubensmalf

Портал для активных https://onlystyle.com.ua стильных, современных женщин. Мода, карьера, здоровье, бьюти-тренды, фитнес, лайфхаки, вдохновение. Будь в курсе, живи ярко, выбирай смело. Никаких скучных статей — только драйв, стиль и реальная польза.

Josephwic

Портал для женщин https://prettiness.kyiv.ua которые любят жизнь во всех её красках. Советы, мода, рецепты, отношения, вдохновение, дом и путешествия. Каждый день — новая идея, интересная мысль и повод улыбнуться.

Wilburnrib

Модный журнал https://psilocybe-larvae.com всё о стиле, трендах, бьюти-новинках, звёздах и вдохновении. Образы с подиумов, советы стилистов, актуальные коллекции, мода улиц и мировые бренды.

MartinDat

Профессиональный массаж Ивантеевка: для спины, шеи, поясницы, при остеохондрозе и сколиозе. Медицинский и спортивный подход, опытные специалисты, точечное воздействие. Снятие болей, восстановление подвижности, улучшение самочувствия.

LesterZen

Онлайн-портал для женщин https://rpl.net.ua всё о жизни, стиле, здоровье, отношениях, карьере, детях, красоте и вдохновении. Полезные статьи, советы, идеи и актуальные темы.

Donaldsob

Женский онлайн-портал https://sweaterok.com.ua это не просто сайт, а поддержка в повседневной жизни. Честные темы, важные вопросы, советы и тепло. От эмоций до материнства, от тела до мыслей.

LouisMug

Онлайн-журнал для женщин https://tiamo.rv.ua которые ищут баланс. Психология, эмоции, отношения, самоценность, женское здоровье. Честные тексты, поддержка, путь к себе. Пространство, где можно дышать глубже, читать с удовольствием и чувствовать, что тебя понимают.

WilliamHausy

Женский онлайн-журнал https://trendy.in.ua о выборе, деньгах, успехе и личных целях. Как совмещать карьеру и семью, строить бизнес, говорить “нет” и заботиться о себе. Истории, советы, интервью, вдохновение. Для тех, кто идёт вперёд — в своих темпах и с опорой на себя.

Daryldoown

Онлайн фитнес-журнал https://bahgorsovet.org.ua полезные статьи от тренеров и нутрициологов: программы тренировок, восстановление, питание, биомеханика, анализ ошибок. Говорим на языке результата. Научный подход без воды — для тех, кто ценит эффективность.

Dannyhob

Всё о лечении диабета https://diabet911.com типы заболевания, симптомы, диагностика, питание, образ жизни и лекарственная терапия. Объясняем просто и понятно. Актуальная информация, советы врачей, статьи для пациентов и близких.

Thomaspen

написать диплом на заказ где купить дипломную работу

Thomasabexy

готовые рефераты https://referatymarketing.ru

Perrysearf

Сайт для женщин https://expertlaw.com.ua которые любят моду, красоту и стильную жизнь. Актуальные тренды, советы по уходу, подбор образов, вдохновляющие идеи для гардероба и макияжа.

JoshuaSap

Сайт о здоровье глаз https://eyecenter.com.ua полезные статьи, советы офтальмологов, симптомы заболеваний, диагностика, лечение, упражнения для зрения. Всё о профилактике, коррекции, очках, линзах и современных методах восстановления.

play aviator

Here, you can access lots of online slots from famous studios.

Users can try out traditional machines as well as new-generation slots with stunning graphics and bonus rounds.

If you’re just starting out or an experienced player, there’s a game that fits your style.

money casino

All slot machines are instantly accessible round the clock and designed for PCs and mobile devices alike.

No download is required, so you can start playing instantly.

Site navigation is easy to use, making it quick to browse the collection.

Join the fun, and enjoy the thrill of casino games!

AndrewneR

Сайт о мужском здоровье https://kakbog.com достоверная информация о гормональном фоне, потенции, урологических проблемах, профилактике, питании и образе жизни. Советы врачей, диагностика, лечение, препараты.

DamonIroni

Современный медицинский портал https://medfactor.com.ua с упором на технологии: телемедицина, онлайн-запись, цифровые карты, расшифровка анализов, подбор препаратов. Удобный доступ к информации и поддержка на всех этапах — от симптомов до выздоровления.

www.linkedin.com

Aviator merges adventure with exciting rewards.

Jump into the cockpit and spin through aerial challenges for huge multipliers.

With its classic-inspired design, the game evokes the spirit of pioneering pilots.

https://www.linkedin.com/posts/robin-kh-150138202_aviator-game-download-activity-7295792143506321408-81HD/

Watch as the plane takes off – claim before it disappears to lock in your winnings.

Featuring smooth gameplay and dynamic sound effects, it’s a favorite for casual players.

Whether you’re looking for fun, Aviator delivers non-stop excitement with every flight.

VernonNaw

Надёжный медицинский портал https://pobedilivmeste.org.ua с удобной навигацией и актуальной информацией. Болезни, симптомы, приёмы врачей, анализы, исследования, препараты и рекомендации.

Alfredpleni

Кулинарные рецепты https://kulinaria.com.ua на каждый день и для особых случаев. Домашняя выпечка, супы, салаты, десерты, блюда из мяса и овощей. Простые пошаговые инструкции, доступные ингредиенты и душевные вкусы.

NelsonIgnob

Сайт для мужчин https://phizmat.org.ua всё о жизни с характером: здоровье, спорт, стиль, авто, карьера, отношения, технологии. Полезные советы, обзоры, мужской взгляд на важные темы.

JosephWaf

Мужской портал https://realman.com.ua всё, что интересно и полезно: спорт, здоровье, стиль, авто, отношения, технологии, карьера и отдых. Практичные советы, обзоры, мнения и поддержка.

ShaunUnuby

Новостной портал https://sensus.org.ua главные события дня в России и мире. Политика, экономика, общество, культура, спорт и технологии. Только проверенные факты, оперативные сводки, мнения экспертов и честная подача.

Allenfuh

медицинский портал https://pobedilivmeste.org.ua с удобной навигацией и актуальной информацией. Болезни, симптомы, приёмы врачей, анализы, исследования, препараты и рекомендации.

TyroneNes

Новостной портал https://sensus.org.ua главные события дня в России и мире. Политика, экономика, общество, культура, спорт и технологии. Только проверенные факты, оперативные сводки, мнения экспертов и честная подача.

同性恋者

这个网站 提供 丰富的 成人资源,满足 各类人群 的 需求。

无论您喜欢 哪一类 的 视频,这里都 一应俱全。

所有 材料 都经过 严格审核,确保 高品质 的 观看体验。

喷出

我们支持 多种设备 访问,包括 电脑,随时随地 畅享内容。

加入我们,探索 绝妙体验 的 成人世界。

Robertemola

займ онлайн официальный сайт взять займ онлайн

RichardGuism

Piano klavier noten noten von klavier

拜物教

这个网站 提供 多样的 成人材料,满足 各类人群 的 需求。

无论您喜欢 哪种类型 的 影片,这里都 种类齐全。

所有 材料 都经过 精心筛选,确保 高清晰 的 视觉享受。

口交

我们支持 多种设备 访问,包括 手机,随时随地 自由浏览。

加入我们,探索 激情时刻 的 成人世界。

ArthurMit

микрозайм взять онлайн займ займ

Danielted

Пианино по нотам пианино по нотам

JoshuaCoege

Гид индивидуальный Калининград https://gid-po-kaliningradu.ru – персональный подход.

Brianwal

На нашем сайте вы найдёте картинки к праздникам для любого случая. Яркие изображения, тёплые слова, праздничное настроение и стильный дизайн. Поделитесь эмоциями с близкими и сделайте каждый день особенным. Обновления каждый день, удобный формат, всё бесплатно!

Marcusvaf

заказать реферат москва реферат написать

TitusDetly

диплом срочно заказать стоимость дипломной работы на заказ в среднем

Brentarill

натяжной потолок в ванну натяжные потолки

Williamthorb

Мы предлагаем отделка ванных комнат с гарантией качества, соблюдением сроков и полным сопровождением. Индивидуальный подход, современные материалы и прозрачные цены. Работаем по договору. Закажите бесплатную консультацию и начните комфортный ремонт уже сегодня!

arenda-avto

заказ автомобиля аренда сколько стоит аренда машины

RickySkews

аренда автомобиля на сутки аренда машины для поездки

pin-up

Here, you can discover a wide range virtual gambling platforms.

Searching for well-known titles or modern slots, there’s something for every player.

All featured casinos are verified for trustworthiness, enabling gamers to bet securely.

gambling

What’s more, this resource offers exclusive bonuses plus incentives to welcome beginners and loyal customers.

Thanks to user-friendly browsing, finding your favorite casino happens in no time, making it convenient.

Stay updated about the latest additions through regular check-ins, because updated platforms appear consistently.

falloutbuy

Играешь в Fallout 76? Хочешь купить хлам Fallout 76? Широкий ассортимент предметов, включая силовую броню, легендарное оружие, хлам, схемы и многое другое для Fallout 76 на PC, Xbox и PlayStation. Мы предлагаем услуги буста, прокачки персонажа и готовые комплекты снаряжения.

falloutbu

Играешь в Fallout 76? Хочешь легендарное оружие Fallout 76? Широкий ассортимент предметов, включая силовую броню, легендарное оружие, хлам, схемы и многое другое для Fallout 76 на PC, Xbox и PlayStation. Мы предлагаем услуги буста, прокачки персонажа и готовые комплекты снаряжения.

diabloshop

На diabloshop.ru вы можете купить https://diabloshop.ru/product-category/diablo-2-ressurected/ золото Diablo 4, руны Diablo 2 Resurrected, а также уникальные предметы и легендарное снаряжение для всех платформ — PC, Xbox, PlayStation и Nintendo Switch. Мы предлагаем быстрый буст персонажа, услуги прокачки, сбор лучших билдов и готовые комплекты снаряжения.

1xbet

On this site, find an extensive selection virtual gambling platforms.

Whether you’re looking for classic games new slot machines, there’s a choice for any taste.

The listed platforms fully reviewed for trustworthiness, allowing users to gamble securely.

1win

Moreover, the site provides special rewards plus incentives for new players and loyal customers.

Thanks to user-friendly browsing, finding your favorite casino happens in no time, making it convenient.

Be in the know on recent updates through regular check-ins, since new casinos come on board often.

ThomasLit

На diabloshop.ru вы можете купить https://diabloshop.ru/product-category/diablo-4/ золото Diablo 4, руны Diablo 2 Resurrected, а также уникальные предметы и легендарное снаряжение для всех платформ — PC, Xbox, PlayStation и Nintendo Switch. Мы предлагаем быстрый буст персонажа, услуги прокачки, сбор лучших билдов и готовые комплекты снаряжения.

KennethMuh

Играешь в Fallout 76? Хочешь силовая броня Fallout 76? Широкий ассортимент предметов, включая силовую броню, легендарное оружие, хлам, схемы и многое другое для Fallout 76 на PC, Xbox и PlayStation. Мы предлагаем услуги буста, прокачки персонажа и готовые комплекты снаряжения.

ekskursii-kaliningrad

экскурсии в калининграде 2025 цены групповые экскурсии калининград

Nathanhef

юрист по семейным делам спб юрист по семейному праву стоимость юриста

Nathanhef

юрист по семейному праву цена https://urwork.ru/uslugi/semejnyj-yurist/

Williamkeype

судебный приказ о взыскании задолженности оказание юридических услуг по взысканию задолженности

pornjourney

Discover Pornjourney AI, a platform where artificial intelligence makes your desires come true. Create your perfect AI heroines, chat in real time, and enjoy personalized content tailored to your tastes. The next level of sex technology is here.

WilfredDiono

Металлические ограждения https://osk-stroi.ru для дома, дачи, промышленных и общественных объектов. Качественные материалы, долговечность, устойчивость к коррозии. Быстрая установка и индивидуальное изготовление под заказ.

NathanFit

Пиломатериалы от производителя https://tsentr-stroy.ru по доступным ценам. В наличии обрезная и необрезная доска, брус, вагонка, доска пола, рейка и другие изделия. Работаем с частными и корпоративными заказами. Качество, доставка, гибкие условия.

Mosesplurn

Инвестиции в строительство https://permgragdanstroy.ru жилой и коммерческой недвижимости. Прибыльные проекты, прозрачные условия, сопровождение на всех этапах. Участвуйте в строительстве с гарантированной доходностью.

Charlesacent

Недвижимость Черноземья https://nedvizhimostchernozemya.ru квартиры, дома, участки, коммерческие объекты. Продажа и аренда во всех крупных городах региона. Надежные застройщики, проверенные предложения, прозрачные сделки.

Robertcet

Агентство недвижимости https://assa-dom.ru покупка, продажа, аренда квартир, домов, участков и коммерческих объектов. Полное сопровождение сделок, помощь с ипотекой, юридическая поддержка. Надежно, удобно, профессионально.

Thomashog

стоимость разработки сайта заказать разработку интернет сайта

Donaldded

сделать металлический бейдж бейджи из полированной латуни на заказ

Edwardvox

шильды корпоративные цена срочное изготовление шильдов

Dexamphetamine

Здесь вы найдете содержание 18+.

Контент подходит для зрелых пользователей.

У нас собраны разнообразные материалы.

Платформа предлагает качественный контент.

Dimethylthiambutene

Вход разрешен после подтверждения возраста.

Наслаждайтесь возможностью выбрать именно своё.

James

Лучшая биржа предлагает простой интерфейс, поддержку русского языка и обучающие материалы, что делает её отличным выбором для новичков. Выбирая лучшие крипто биржи, обращайте внимание на безопасность, комиссии и наличие поддержки. Начинайте с проверенных платформ и всегда изучайте отзывы пользователей.

DonaldTom

¡Saludos, expertos en casinos !

mejores casinos online chile

Retirar dinero casino chile: mГ©todos rГЎpidos y seguros – п»їhttps://www.youtube.com/watch?v=CRuk1wy6nA0

Jugar sin depГіsito chile es una alternativa excelente para quienes desean probar suerte sin arriesgar su dinero. Con solo registrarte, puedes acceder a bonos y juegos seleccionados. Es la forma perfecta de explorar un nuevo casino.

¡Que disfrutes de botes impresionantes !

JustinLam

Займ без отказа займы онлайн на карту без отказа срочно

Eugenedic

Оставить заявку на займ деньги на карту сразу

VicenteQuoli

Взять микрозайм займ взять

RussellGig

раскрутка сайта дешево https://seoprocessoptimization.ru

Anthonyepisa

изготовление шильда шильды корпоративные цена в москве

Melvinquime

шильдик из латуни изготовление шильд на заказ

DanielElded

Нужен двигатель или акпп? https://motoreuro.ru с гарантией и доставкой по России? Мы предлагаем проверенные агрегаты с пробегом до 100 тыс. км из Японии, Европы и Кореи. Подбор, установка, оформление документов — всё под ключ.

DonnieGar

Бесплатная панель управления 1Panel сервером с открытым исходным кодом. Удобный интерфейс, поддержка популярных ОС, автоматизация задач, резервное копирование, управление сайтами и базами. Оптимально для вебмастеров и системных администраторов.

WilliamZen

смотреть лучшие юрист лучшие юристы

Jamesadoky

headless web browser headless chrome

devrum

цифровизация финансовых услуг разработка системы поставок

DwightNek

металлический бейдж с гравировкой металлические бейджи

znachki-zakaz

изготовление значков москва пины на заказ

DavidSmace

металлические значки москва значки на заказ москва

Stevetuh

металлические значки на заказ значки на заказ москва

Donniebip

поисковое продвижение сайтов стоимость seo продвижения

AlonzoGed

создание и продвижение продающих сайтов раскручивать сайт цена

prodat rolex_haMr

продать ролекс [url=https://www.prodaja-rolex-chasi12.ru]продать ролекс[/url] .

KennethNen

типография печать цифровая типография

JamesCeasp

типография недорого типография организация

WilliamSmure

печати типография спб типография спб цены

Jerrysaw

типография заказ https://tipografiya-spb11.ru

prodat rolex_ivEl

продать часы rolex [url=https://prodaja-rolex-chasi13.ru/]продать часы rolex[/url] .

liga chempionov_hyMl

лига чемпионов футбол [url=https://www.footballnews.store]https://www.footballnews.store[/url] .

Donaldcex

High-end timepieces never lose relevance for numerous vital factors.

Their craftsmanship and tradition define their exclusivity.

They symbolize status and success while blending functionality with art.

Unlike digital gadgets, their value grows over time due to exclusive materials.

https://loveyou.az/read-blog/23269

Collectors and enthusiasts treasure the engineering marvels that no gadget can ever equal.

For many, having them signifies taste that goes beyond fashion.

remont okon_wzOa

ремонт окон [url=https://studio5floor.ru/]https://studio5floor.ru/[/url] .

zaimi_epMa

займы [url=https://investinq.ru/]investinq.ru[/url] .

prodat rolex_akMr

ломбард rolex [url=www.prodaja-rolex-chasi12.ru]www.prodaja-rolex-chasi12.ru[/url] .

remont okon_reOa

пластиковые окна [url=https://studio5floor.ru]https://studio5floor.ru[/url] .

Henryfiems

Ищете, где https://motoreuro.ru с гарантией и доставкой? Мы предлагаем проверенные агрегаты с пробегом до 100 тыс. км из Японии, Европы и Кореи. Подбор, установка, оформление документов — всё под ключ.

KennethDycle

печать визиток в москве недорого изготовление печать визиток

Blakeadoke

печать двусторонних визиток печать визиток в москве недорого

Stanleybiawn

Все для планшетов – новости, обзоры устройств, игр, приложений, правильный выбор, ответы на вопросы https://protabletpc.ru/

stanki-a

Станки для производства купить листогиб металлообработка, резка, сварка, автоматизация. Продажа новых и восстановленных моделей от ведущих брендов. Гарантия, обучение персонала, техподдержка.

Brucefed

The real-time analysis feature is worth mentioning. The AI-driven analytics help to filter out irrelevant footage, which reduces false alarms and unnecessary recordings. It’s incredibly accurate when detecting motion, and the object recognition feature is spot on, helping me to monitor specific areas of interest. Whether it’s identifying faces or vehicles, Smart Vision does it all with ease. Security Camera Software

zaimi_fuMa

онлайн займы [url=http://investinq.ru]http://investinq.ru[/url] .

Branttot

Актуальные статьи с полезными советами по строительству и ремонту. Каждый найдет у нас ответы на самые разнообразные вопросы по ремонту https://masteroff.org/

prodat rolex_aqEl

скупка ролекс [url=prodaja-rolex-chasi13.ru]скупка ролекс[/url] .

liga chempionov_loMl

лига ставок футбол [url=https://footballnews.store/]footballnews.store[/url] .

JamesBor

Новости экономики России, зарплаты и кредиты, обзоры профессий, идеи бизнеса и истории бизнесменов. Независимая экономическая аналитика и репортажи https://iqreview.ru/

AndrewPoemy

Pursue a PhD in Computer Science and contribute to cutting-edge research at Satbayev University. Learn about doctoral supervision, publication requirements, and funding for software development, algorithms, data structures https://satbayev.university/

Jeffreyrerty

Онлайн сервис быстрое скачивание изображений с сайта для получения картинок с любого сайта. Вставьте URL — и мгновенно получите изображения на своём устройстве. Поддержка всех форматов, никаких ограничений и лишних действий. Работает бесплатно и круглосуточно.

Michaelvot

Старый Лекарь болезни и лечение – Лекарь расскажет: лекарственные травы, болезни и лечение, еда, массаж, диеты и правильное питание https://old-lekar.com/

CharlesFlert

Актуальные мировые события. Последние новости, собранные с разных уголков земного шара. Мы публикуем аналитические статьи о политике, экономике, культуре, спорте, обществе и многом ином https://informvest.ru/

1win_gpPr

1вин про [url=https://www.1win22080.ru]https://www.1win22080.ru[/url] .

pechat-nakleek

Изготовление и https://pechat-nakleek44.ru. Стикеры для бизнеса, сувениров, интерьера и упаковки. Печатаем тиражами от 1 штуки, любые материалы и формы. Качественно, недорого, с доставкой по СПб.

nakleyki-pechat

Нужна печать объемных наклеек? Закажите стикеры любых форм и размеров с доставкой. Яркие, прочные, влагостойкие наклейки на пленке и бумаге — для рекламы, декора, маркировки и упаковки.

tipografiya-spb

Профессиональная продукция типографии. Изготовим любые печатные материалы — от визиток до каталогов. Качественно, быстро, с гарантией. Закажите онлайн или приезжайте в офис в СПб.

Martinnic

Актуальные новости. Все про политику, культуру, общество, спорт и многое другое ежедневно на страничках нашего популярного аналитического блога https://mozhga18.ru/

Richardspelm

проститутки с выездом

1win_ohPr

1win online [url=https://1win22080.ru/]1win online[/url] .

Richardspelm

самые красивые проститутки тюмень

AurelioFes

Блог, посвященный любителям самоделок. Интересные статьи по теме стройки и ремонта, авто, сада и огорода, вкусных рецептов, дизайна и много другого, что каждый может сделать своими руками https://notperfect.ru/

Danielcix

Модные образы для торжеств этого сезона отличаются разнообразием.

Актуальны кружевные рукава и корсеты из полупрозрачных тканей.

Детали из люрекса придают образу роскоши.

Многослойные юбки становятся хитами сезона.

Особый акцент на открытые плечи создают баланс между строгостью и игрой.

Ищите вдохновение в новых коллекциях — стиль и качество сделают ваш образ идеальным!

http://minimoo.eu/index.php/en/forum/suggestion-box/732284-2025

Donaldsut

Самые интересные и полезные статьи на тему настройки и оптимизации работы компьютеров и оргтехники https://www.softo-mir.ru/

Richardspelm

телефон проституток тюмени

Morrisdyept

https://www.ukrinformer.com.ua/

DanielAMBUT

Ежедневные публикации про новинки автомобилей, советы по ремонту и эксплуатации, мастер-классы тюнинга, новое в правилах ПДД и автомобильных законах в нашем блоге https://mineavto.ru/

prodvijenie saitov_rmSt

продвижение сайта в топ москва [url=https://prodvizhenie-sajtov-v-moskve.ru]https://prodvizhenie-sajtov-v-moskve.ru[/url] .

1win_uz_mjPi

lucky jet игра скачать [url=http://1win14005.ru/]http://1win14005.ru/[/url] .

Stanleywrart

Интернет-магазин https://antibrand.shop брендовой одежды для мужчин и женщин. Оригинальные коллекции, актуальные тренды, быстрая доставка и гарантия качества. Покупайте стильные вещи от мировых брендов онлайн — удобно, безопасно, выгодно.

PatrickTainc

Профессиональная студия лазерной эпиляции спб. Эффективное удаление волос на любом участке тела, подход к любому фототипу. Сертифицированные специалисты, стерильность, скидки. Запишитесь прямо сейчас!

RobertSlata

Удаление волос https://lazernaya-epilyaciya-spb1.ru: гладкая кожа на долгое время. Аппараты последнего поколения, опытные мастера, комфортная обстановка. Эпиляция для женщин и мужчин. Онлайн-запись, гибкие цены, без лишнего стресса.

Josepharren

Безболезненная сколько делать лазерную эпиляцию Удаление волос на любом участке тела. Работаем с чувствительной кожей, используем новейшие лазеры. Акции, абонементы, индивидуальный подход.

prodvijenie saitov_buSt

продвижение сайты топ 10 [url=www.prodvizhenie-sajtov-v-moskve.ru]www.prodvizhenie-sajtov-v-moskve.ru[/url] .

Christet

СамСтрой. Блог о ремонте и строительтве для каждого! Полезные советы, фото и видео материалы про стройку и ремонт, дизайн интерьера, а также приусадебный участок https://biosferapark.ru/

mostbet_uxpl

mostbet az [url=https://mostbet3042.ru/]https://mostbet3042.ru/[/url] .

LewisJal

карта повітряних тривог

mostbet_vhoa

mostbet android yukle [url=https://mostbet3043.ru]mostbet android yukle[/url] .

JamesGeora

нанять грузчиков недорого грузчики на заказ

Josephnomia

https://profi64.ru/

MichaelDiorn

недорогие грузчики грузчик нанять

Briancrarf

заказать услуги грузчиков грузчик срочно

mostbet_mcma

мостбет лицензия [url=mostbet3030.ru]mostbet3030.ru[/url] .

Briancrarf

услуга грузчиков грузчики срочно

Michealsew

услуги грузчиков грузоперевозки услуги грузчиков городу

AlfredPlego

https://stadium.ru/news/partners/24-04-2025-vidi-diagnostiki-zdorovya

magazin-soft

программное обеспечение windows купить программное обеспечение компьютера купить

Michaelvof

Избавьтесь от волос лазерная эпиляция волос навсегда — с помощью лазерной эпиляции. Эффективные процедуры на любом участке тела, минимальный дискомфорт, заметный результат уже после первого сеанса.

Lesterver

https://gonzo-casino.pl/

Charlieemort

семейный медицинский центр центр медицинских услуг

DennisLom

доставка цветов дешево https://dostavka-cvetov1.ru

Josephnomia

https://polimernypol.ru/

1win_uz_jaPi

получить деньги за регистрацию без вложений с выводом на карту [url=1win14005.ru]1win14005.ru[/url] .

1win_okoi

1 вин ставка [url=https://1win22083.ru]https://1win22083.ru[/url] .

klinicheskie analizi_nkma

сдать анализ в клинике [url=https://medanalyze.ru/]medanalyze.ru[/url] .

dostavka edi_obPr

доставка еды челябинск круглосуточно [url=http://www.dostavka-edy-bf11.ru]доставка еды челябинск круглосуточно[/url] .

dostavka edi_nwPt

заказать обед с доставкой челябинск [url=http://www.dostavka-edy-bf12.ru]http://www.dostavka-edy-bf12.ru[/url] .

dostavka edi_yfei

заказать еду в челябинске с доставкой [url=http://dostavka-edy-bf13.ru]http://dostavka-edy-bf13.ru[/url] .

HarleyAttet

доставка цветов на дом спб доставка цветов недорого

Lesterver

https://gonzo-casino.pl/

mostbet_izoa

mostbet virtual idman [url=http://mostbet3043.ru/]mostbet virtual idman[/url] .

klinicheskie analizi_xkma

сдать анализ в клинике [url=https://medanalyze.ru/]medanalyze.ru[/url] .

dostavka edi_yiPt

доставка еды челябинск [url=dostavka-edy-bf12.ru]доставка еды челябинск[/url] .

dostavka edi_mhPr

доставка еды обеды челябинск [url=www.dostavka-edy-bf11.ru/]доставка еды обеды челябинск[/url] .

1win_amen

скачать lucky jet 1win [url=www.1win22084.ru]www.1win22084.ru[/url] .

mostbet_vnpl

mostbet azerbaycan rəsmisi [url=http://mostbet3042.ru]http://mostbet3042.ru[/url] .

dostavka edi_ijei

здоровая ферма [url=http://dostavka-edy-bf13.ru]http://dostavka-edy-bf13.ru[/url] .

Lesterver

https://gonzo-casino.pl/

FelixCob

телефон медицинского центра https://medicinskiy-centr-abakan11.ru

Davidraf

узи органов где сделать узи

JorgeReorm

взрослый дерматолог дерматологи абакана отзывы

1win_txei

1win официальный сайт войти [url=www.1win14004.ru]1win официальный сайт войти[/url] .

1win_mlkn

1win ruxsatnoma [url=http://1win14006.ru]1win ruxsatnoma[/url] .

mostbet_iwOt

мостбет промокод на бонус [url=http://mostbet3031.ru/]http://mostbet3031.ru/[/url] .

1win_hnkn

1win mobil yuklash ios [url=https://1win14006.ru]1win mobil yuklash ios[/url] .

1win_rtei

1win регистрация онлайн [url=http://1win14004.ru]http://1win14004.ru[/url] .

kkyeaflgp

Stable Games Ltd, having its registered address at 206, Wisely house, Old Bakery Street, Valletta VLT 1451, Malta, is licensed and regulated by the Malta Gaming Authority to supply Type1 gaming services under a B2B Critical Gaming Supply Licence (Licence Number: MGA B2B 785 2020, issued on 18th March 2021). Mega Evolution goes beyond the limits of regular Evolution. Only certain Pokémon can Mega Evolve. Doing so imparts power greater than regular Evolution by temporarily unleashing the energy hidden within the Pokémon. Pokémon change their appearance when they Mega Evolve, and certain Pokémon may even change types. The reasons are logical enough. But the Space XY game does not allow you to play the demo mode. It would seem that now you will not be able to test the game without risks. But for you, they made the functionality of monitoring other people’s rates. Study the bets of other players, rounds, who shoots at what odds, with what frequency. It is easier and easier to learn from the experience of real players than by playing on your own with 0 balance.

https://surfslipunde1985.iamarrows.com/https-i-thimblesgame-com

The game is played on a 5×5 grid, with each tile hiding either a chicken or a bone. Players choose which tiles to flip, and for every chicken they uncover, their winnings increase. However, if they reveal a bone, the game ends, and they lose everything they’ve accumulated during that round, including their original bet. The game combines both luck and strategy, as players can choose to stop and collect their winnings or risk it all to find more chickens for a bigger payout. That’s because Ukraine took matters into its own hands after Russia backed out in 2023 of the earlier deal to ensure safe Black Sea shipping. Ukraine carved out a trade route requiring ships to sail near the coast lines of Bulgaria and Romania, guided by the Ukrainian Navy. At the same time, Ukrainian forces launched a campaign of sea drone attacks to further push back Russia’s fleet.

Danielsnada

https://biotpharm.com/# Over the counter antibiotics pills

HarryNax

https://www.asseenontvonline.ru/

mostbet_hsma

мостбеи [url=mostbet3030.ru]mostbet3030.ru[/url] .

BruceRub

Ритуальные агенты помогут вам в трудные моменты. Мы обеспечим весь спектр услуг по организации похорон, предоставив консультации и поддержку на всех этапах – https://pohoronnoe-agentstvo.kz/

JamesWaxia

терапевт абакан отзывы терапевт центр

Javierempot

джипити бот GPT Chat

Jerryonerm

Квартирный и офисный https://declarant-iv.livejournal.com/20546.html переезд под ключ с грузчиками. Бережная упаковка, погрузка, транспортировка и сборка мебели. Быстро, аккуратно, по доступной цене. Работают опытные специалисты.

BruceRub

Транспортировка “Груз 200” по Казахстану и за границу, включая все необходимые документы для транспортировки. Мы предоставляем транспортные услуги с максимальным комфортом – https://pohoronnoe-agentstvo.kz/

Harveyceasy

הזין המוכתם בתחתונים. “אתה אמיץ, ואפילו עם הרבה… – ממש כאן? אפילו לא התביישת? הוא בלע. – לא נעשתה לא אחידה, ואצבעותיה בשערו התכווצו מעט. העולם סביבו נעלם-הם היחידים שנותרו: שפתיו, נערות ליווי בראשון לציון

Harveyceasy

ופחדתי אפילו לנשום כולם חשבו שכרגע נערות ליווי יקפצו מהחושך ויחלידו את הבדיחה הזו אז הייתי על ידי מצב הרוח של הציבור הסובב אותנו, אשתי ואני שוקלים דירות דיסקרטיות בהן ניתן לעשות זאת. דירה דיסקרטית באר שבע

AndrewMoita

הם העיקר. אם אתה לא אוהב משהו, פשוט תגיד לא. כאן אף אחד לא מכריח אותך לעשות משהו שאתה לא זיעה, עץ ומין, הפכה למערה המושחתת שלנו. סבטקה הייתה במרכז, ודפקנו את הדירות המאופקות שוב these details

Ysilenie konstrykcii_klMi

Инъектирование стен [url=http://www.usileniekonstrukcij1.ru]http://www.usileniekonstrukcij1.ru[/url] .

BruceRub

Мы предлагаем ритуальный транспорт в Алматы, включая катафалки, автобусы и микроавтобусы для перевозки покойного и сопровождающих: ритуальный транспорт в Алматы – катафалки, автобусы и микроавтобусы

DonaldDew

שנשרפה כמו מדורה בלבה הרועד … ההדים שרקדו בעיניים מקסימות עם הבזקים שובבים, מוכנים לשירות האמת. תמונות עטופות בראשי: ציצים גדולים של נערת ליווי, עור חשוף, רטוב מאדים באמבטיה … הירח דירה דיסקרטית ראשון לציון

AndrewMoita

שלי עושה שם אבל לא שמתי לב לשום דבר פלילי, כדבריה. וככל שישבנו זמן רב יותר, כך הוא נעשה רגוע עצמה נתנה לי עיסוי בבית כמה פעמים כשהגב או הצוואר שלי כואבים. שמתי על קצה המיטה של ההורה find more

Williamnal

дешево заказать грузчиков грузчики услуги

Harveyceasy