Air pollution control is a critical challenge for many industrial facilities. Any manufacturing facility that produces odors, volatile organic compounds (VOCs), or other hazardous air pollutants (HAPs) must follow stringent rules regulating emissions content. Eliminating pollutants from exhaust keeps the company compliant with government regulations and prevents emissions from harming our environment. Thermal oxidizers can offer a cost-effective, energy-efficient way to perform this critical emissions cleaning process.

Similar to thermal oxidizers are catalytic oxidizers (Catox) are also effective at removing pollutants from manufacturing processes and can achieve up to 99.9% removal efficiency. Review our Catalytic Oxidizer page for more information on capabilities and applicability.

This page will explain all about thermal oxidizers: their features, function, types, applications, costs, and other considerations when selecting an ideal thermal oxidizer for your project.

What Is a Thermal Oxidizer?

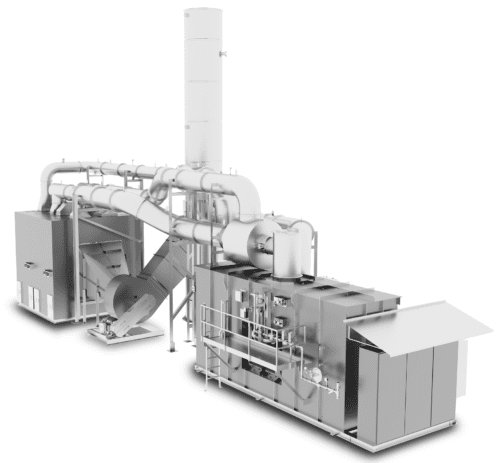

Thermal oxidizers integrate with industrial ventilation systems to process pollutants before they are released into the environment. As combustion devices, thermal oxidizers heat fumes to approximately 1500 °F (815 °C). At this temperature, hydrocarbon-based pollutants undergo oxidation, which converts them into heat, water (H2O), and Carbon Dioxide (CO2). These less harmful vapors are then cooled and emitted in lieu of the original HAPs and VOCs.

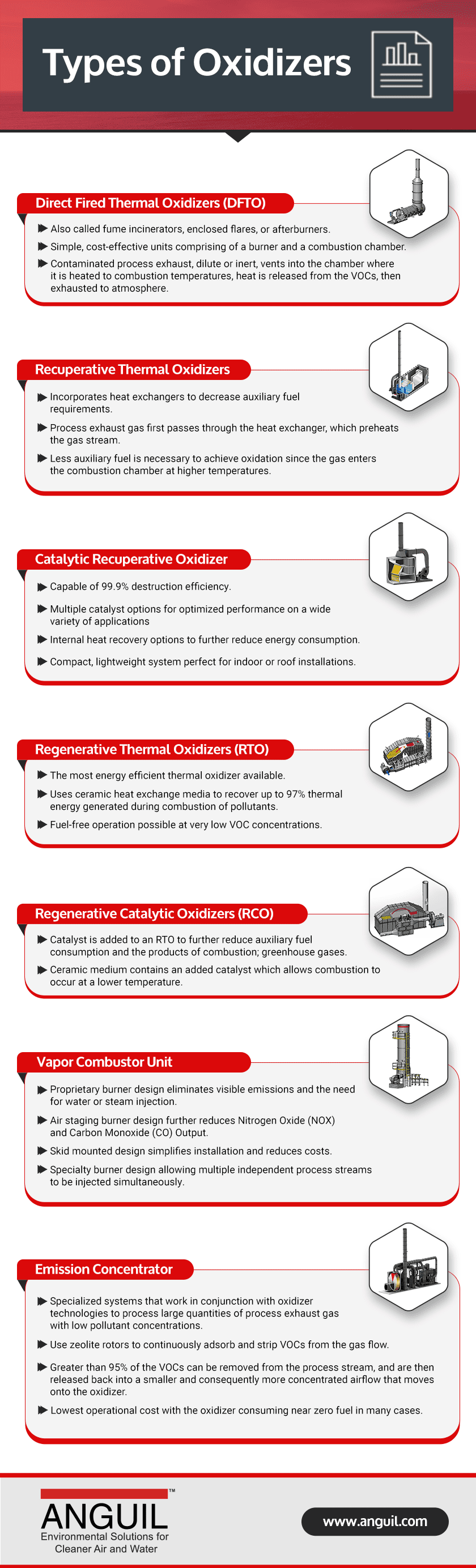

Although all thermal oxidizers perform this same essential function, different types of thermal oxidizers can be used in varying industrial settings. One way that thermal oxidizers can be differentiated is by the presence of heat exchange systems. Nonrecuperative and direct-fired thermal oxidizers are the simplest models, consisting of just a burner and a combustion chamber. In contrast, recuperative and regenerative oxidizers use some form of heat exchanger to improve thermal efficiency and reduce greenhouse gas output.

Thermal oxidizers can be coupled with an emission concentrator to reduce the amount of treated airflow by as much as 95%

How Do Thermal Oxidizers Work?

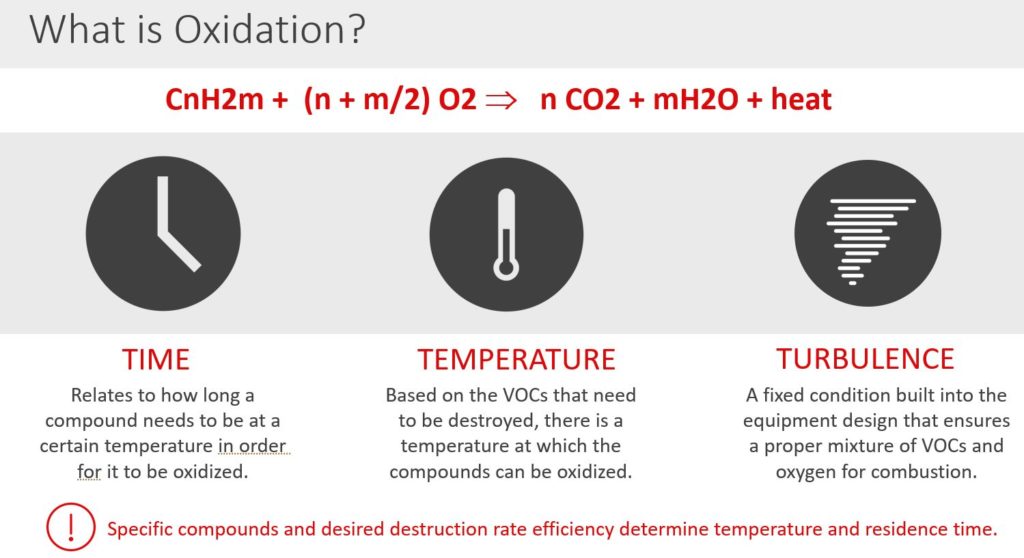

First, the stream of emissions must be directed into the oxidizer in either a forced draft or induced configuration. Ambient air may be added if the ventilated stream does not contain enough oxygen for combustion to occur.

Emissions in nonrecuperative oxidizers do not undergo preheating before combustion, whereas recuperative oxidizers utilize a heat exchanger to preheat the air. Oxidizers with heat exchangers increase fuel efficiency and decrease operating costs, but oxidizers without them incur lower capital and maintenance costs. Whether or not the air has been pre-warmed, once in the combustion chamber, the air is heated between 1400 °F to 1600 °F (760 °C to 871°C). These extreme temperatures are necessary to ensure that all VOCs and HAPs undergo combustion, breaking down completely into heat, water, and carbon dioxide vapors. For most applications, this destruction requires a dwell time of 0.5 to 1.0 seconds.

Just as the oxidizer’s design determines how air enters, it also determines how the treated air is released. If the system has a heat exchanger, the air moves through the hot pass of the heat exchanger and is cooled before being released. Otherwise, the processed stream can be exhausted directly into the atmosphere.

Sufficient time, temperature and turbulence are required to ensure proper emission oxidation.

Thermal Oxidizer Types

The type of thermal oxidizer affects how processing works. The primary subtypes of thermal oxidizers are:

- Direct Fired Thermal Oxidizers (DFTO): Also called fume incinerators, enclosed flares, or afterburners, direct-fired thermal oxidizers are simple, cost-effective units comprising a burner and a combustion chamber. Contaminated exhaust vents directly into the chamber, where it is heated and then released. Anguil’s DFTOs can achieve a destruction rate exceeding 99.9% efficiency.

- Recuperative Thermal Oxidizer: Recuperative oxidizers incorporate heat exchangers to decrease fuel requirements. Pollutant-laden air first passes through the heat exchanger, which preheats the airstream. Since this air enters the combustion chamber at higher temperatures, less fuel is necessary to achieve oxidation. Anguil’s recuperative thermal oxidizers are available in various configurations to accommodate different types of contaminants. They run efficiently with low operating costs, achieving destruction rates over 99.9%.

- Regenerative Thermal Oxidizer (RTO): Regenerative oxidizers are the most energy-efficient oxidizers available, using ceramic heat exchange media to recover up to 97% of thermal energy generated in processing. This capacity significantly reduces operating costs and fuel consumption, with the fuel-free operation being possible at very low VOC concentrations.

- Regenerative Catalytic Oxidizers (RCO): Regenerative catalytic oxidizers decrease fuel consumption even further compared to RTOs. Their overall design is the same, with a ceramic heat exchange media recapturing almost all of the heat that is produced. The difference is that the ceramic medium in an RCO contains an added catalyst, which allows combustion to occur at a comparatively lower temperature. This means that even less energy and fuel are required to sustain the necessary oxidation temperature.

- Rotary Concentrators: Emission concentrators are specialized systems that process large quantities of polluted air with low pollutant concentrations. They use zeolite rotors to continuously strip and adsorb VOCs from the airflow. Approximately 95% of the VOCs can be removed from the process stream which are then released back into a smaller and consequently more concentrated airflow that moves into the oxidizer. Not only is this process more efficient for low-concentration polluted airstream, but it is extremely cost-effective, with the oxidizer consuming nearly zero fuel in many cases.

Thermal Oxidizer Applications and Uses

Thermal oxidizers can be used in any facility that outputs VOCs and HAPs. Common processes that call for pollutant capture include painting, coating, printing, mining, chemical processing, and more.

Industries that rely on oxidizers to manage air quality include:

- Automotive Manufacturing

- Chemical Processing

- Coating & Converting

- Composites & Carbon Fiber

- Electronics & Semiconductors

- Energy & Heat Recovery

- Food & Beverage Processing

- Metal Coating

- Mining

- Natural Gas

- Painting & Spraying

- Pharmaceutical & Medical Devices

- Printing & Packaging

- Refining & Petrochemical

- Soil & Groundwater Remediation

- Renewable Energy

- Rubber Curing

Anguil has served clients from all of these sectors, so our team has the expertise necessary to deliver custom solutions for your needs.

Thermal Oxidizer System Costs and Considerations

When investing in a thermal oxidizer, it’s important to consider both the upfront capital investment as well as ongoing operating costs. Capital costs include the cost of the equipment plus shipping and installation while operating costs include recurring expenses for fuel, electricity, compressed air, and maintenance services. In general, recuperative and regenerative oxidizers have lower operating costs due to their efficient heat recovery. However, the best option depends on the type and concentration of pollutants as well as the volume and oxygen concentration of the process air.

Operating costs can be reduced with careful management strategies. These can be as simple as tracking performance metrics, performing routine maintenance, and optimizing heat recovery systems. Maintaining proper documentation is also key—it ensures that systems receive comprehensive and timely maintenance, extending their working life.

Considerations When Purchasing a Thermal Oxidizer

When investing in or upgrading a thermal oxidizer, there are many considerations to take into account:

- Type of oxidizer: First, ensure a thermal oxidizer is necessary for your application. In some cases, a catalytic oxidizer could be a better choice.

- Type of heat exchanger: For recuperative thermal oxidizers, shell and tube heat exchangers are generally more durable than plate heat exchangers, especially when handling airstreams with particulates. Regenerative thermal oxidizers utilize ceramic energy recovery media that comes in various sizes for handling a wide range of conditions. Consult an expert to determine the optimum media selection.

- Analyze upstream airflow: A primary contributor to capital costs and operating expenses of an oxidizer is airflow. Look at upstream processes to ensure you are not treating unnecessary sources.

- Presence of particulate matter: The size and quantity of particulate matter also influence tube size requirements of a recuperative system. The RTO bake-out capabilities are beneficial if the particulate buildup is expected.

- Local regulations: Low NOx burners help ensure your facility remains compliant with evolving emissions standards for nitrogen oxidizes.

- Need for secondary heat exchange: Consider whether your facility would benefit from secondary heat recovery. For example, if another process requires steam, secondary heat exchange might be a cost-effective choice in the long run.

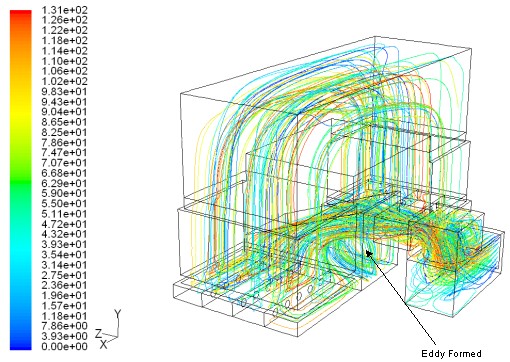

Hot spots and wear points can be avoided by performing velocity modeling during oxidizer design.

The team at Anguil can help you weigh all of these considerations as they relate to your unique application.

Thermal Oxidizers from Anguil Environmental

Anguil offers a wide range of high-performance industrial oxidizers to suit varied destruction requirements, efficiency preferences, and process parameters. Each system has a unique design, but all our solutions adhere to rigorous quality standards, offering reliable and efficient pollutant capture. Discover more by checking out our oxidizer application datasheet. Contact us today to learn which oxidizer would best benefit your application.