The United States consumes an estimated 322 billion gallons of water daily. Industrial applications account for nearly half this total usage.

Industrial wastewater presents tremendous challenges to companies and the communities they operate within. The amount of water consumed, plus the significant effluent produced by industrial clients poses great challenges and costs for both the industrial client and the local municipality.

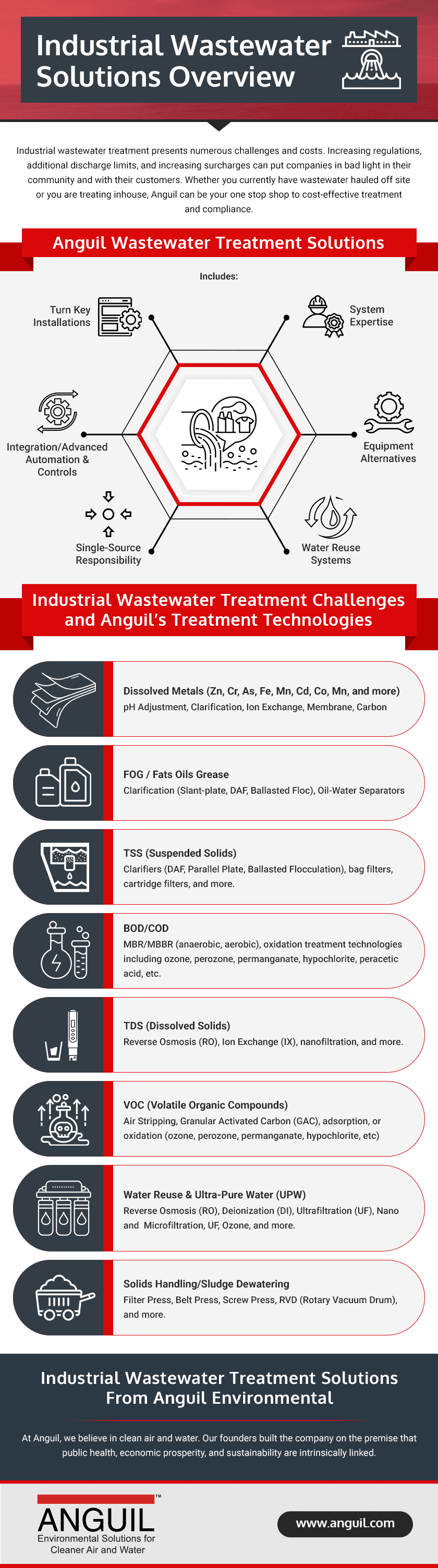

Companies must adequately manage any contaminants generated during their production processes. If a company fails to address its wastewater treatment properly, it can lead to high costs related to surcharges or fines, or it can pay high costs for hauling and disposal. For these and other reasons, efficient industrial wastewater treatment technologies are crucial for fiscal, environmental, and reputational reasons.

Read on to learn more about industrial wastewater treatment processes and the available options for your application.

Industrial Wastewater

Many industrial facilities install pretreatment plants to mitigate the environmental impact of highly contaminated wastewater. Different kinds of wastewater contamination require different strategies to facilitate the proper removal of contaminants. These treatment systems remove solids, VOCs, metals, fats, oils, grease, and other contaminants to ensure regulatory compliance. Industrial companies are also responsible for the proper disposal of solids generated by their treatment process.

Industrial Wastewater Treatment Challenges

Companies that need to pretreat wastewater before they send it to the municipality face several major issues. Infrastructure problems and regulatory pressures are two of the biggest challenges.

Aging Infrastructure and Investment Dilemmas

Aging equipment is a growing concern for many industrial clients that generate wastewater. Many treatment systems that have been running for decades often rely on cobbled-together solutions and the expertise of the employee to manually maintain functionality. This situation puts companies in a difficult position regarding future investments.

They must weigh the costs of major upgrades against implementing entirely new treatment systems. The impending retirement of experienced operators adds urgency to these decisions. A constant threat of system failure and discharging wastewater above permitted discharge limits also pushes companies toward action.

Regulatory Changes and Compliance Efforts

Publicly Owned Treatment Works (POTWs) sometimes revise their discharge limits. These changes force industrial clients to improve their system performance. Such revisions typically happen when industrial growth strains a POTW’s ability to meet residential needs.

Municipalities find it more cost-effective to tighten standards for industrial clients rather than expand their own facilities. This approach helps reduce the burden on the municipal treatment system. Industrial companies then face the challenge of finding economical ways to meet these new criteria to avoid penalties and surcharges.

Cost Reduction and Process Optimization

In recent years, companies have created initiatives to reduce costs and risks with their wastewater. Many companies that were spending money to haul and dispose of their wastewater have seen significant cost increases and are exploring in-house treatment as an option. Others are looking to upgrade their systems due to more stringent standards, cost or loss od labor, expansion, and even reuse of process water.

One challenge they face is finding a cost-effective manner to properly troubleshoot their current process and have the certainty that whatever solution or system is proposed is the best available treatment approach from a cost and risk standpoint.

Anguil is a system integrator that provides new systems, as well as upgrades to existing treatment systems. Anguil leverages our 45+ engineers and an additional 80 technical and operational personnel to help industrial organizations efficiently and effectively treat and process wastewater.

We conduct trials to optimize various treatment approaches and provide detailed cost estimates for different options. This information covers both upfront expenses and ongoing operational costs. Facilities operators can then use these insights to make informed decisions about improving their processes.

Industrial Wastewater Treatment Solutions

The primary focus of most wastewater treatment solutions is to discharge wastewater in compliance with national and local regulations. The secondary goal is to be as cost-effective as possible when treating wastewater.

Anguil’s Approach to Wastewater Treatment

Anguil is a trusted and experienced Systems Integrator. We provide comprehensive, single-source industrial wastewater treatment solutions. Our projects follow a structured 4-step process:

- We start by collaborating closely with our clients to understand their challenges, specific needs, and key decision criteria.

- The second step involves conducting wet lab trials for each potential treatment option at our facility. We tailor these experiments to meet the client’s criteria and validate potential treatment technologies. Our team then analyzes the results and prepares a detailed report. It details how each option aligns with or challenges the client’s requirements.

- The third step involves pilot testing at the client’s site (if necessary). This allows us to further validate different technologies and treatment approaches under real-world conditions. During this phase, we provide detailed comparisons of capital costs (CAPEX) and operational costs (OPEX) for each potential solution.

- The project execution phase could include fully engineered, build-to-specification, turnkey, and customized solutions. Depending on project requirements, this may involve new equipment installations, retrofits, or system upgrades.

Importance of Technology Alignment with Your Needs

Considering long-term maintenance costs is essential when designing a system. Here are a few key design principles to consider for low-maintenance systems:

- Selecting the right equipment for the specific contaminants: Matching water treatment technologies to targeted pollutants is imperative if you want cost-effective and efficient operation. If multiple treatment options are available, Anguil can provide you with the pros and cons of each so you can make the most informed decision as to what is best for your company.

- Designing for easy operation: With most systems, you can determine the amount of automation that is right for your organization. If you have limited resources, many treatment systems can have a majority of the process automated to minimize human involvement. If cost is the only driver and resources to operate are available, we can leverage a more manual approach and save some capital.

- Focus is on success: Any upgrade or new system will be focused on successful treatment. A system that keeps you compliant mitigates risk to your pocketbook and reputation.

Additional Capabilities and Client Communication

Besides system retrofits, upgrades, and the integration of automated options to reduce human involvement, Anguil can provide solutions for water reuse or (near) zero liquid discharge (nZLD and ZLD) if required.

We maintain constant and open communication with the client throughout this process. We discuss how potential solutions align with their decision criteria and address any concerns. This collaborative approach ensures a final proposal and execution plan that clearly defines scope and handoffs.

At Anguil, our industrial wastewater solution consists of:

- System Expertise

- Equipment Alternatives

- In-House Capabilities

- Single-Source Responsibility

- Integration Capabilities

Industrial Wastewater Treatment Solutions: Technologies

Industrial wastewater solutions use a variety of technologies. The following are some of the materials these systems remove and the technologies used to remove them:

- Heavy metals/dissolved metal materials can be removed through pH adjustment and clarification, ion exchange, and carbon technologies.

- Dissolved Air Flotation (DAF) and oil-water separators remove fats, oils, and grease from wastewater.

- Filter presses, belt presses, rotary vacuum drums, and rotary screw presses squeeze water from sludge to achieve dewatering.

- Cartridge filters, ballasting, parallel plate clarifiers, DAF, and bag filters remove suspended solids.

- MBBR, MBR, anaerobic, anoxic, bioreactor, and oxidation treatment eliminates soluble biochemical oxygen demand (BOD) and chemical oxygen demand (COD).

- Total dissolved solids (TDS) are the measurement of the total dissolved amount of organic and inorganic solid materials present in wastewater. Reverse osmosis, ion exchange systems, and nanofiltration facilitate the removal of TDS.

- Volatile organic compounds (VOCs) are often present in wastewater, requiring removal via air stripping, granular activated carbon (GAC) adsorption, or oxidation.

- Ultra-pure water requires the removal of minerals and other contaminants from relatively clean water. Reverse osmosis (RO), deionization (DI), ion exchange, ultrafiltration (UF), and microfiltration are a few technologies that can be leveraged to create ultra-pure process waters.

Industrial Wastewater Treatment Solutions From Anguil Environmental

At Anguil, we believe in clean air and water. Our founders built the company on the premise that public health, economic prosperity, and sustainability are intrinsically linked. Click below to explore our treatment solutions or contact one of our engineers for more information.

Comments are closed