Crafting Your Oxidizer Maintenance Plan

Comments Off on Crafting Your Oxidizer Maintenance PlanThe Challenge

OXIDIZER SERVICE SERIES: PART 2

Having documentation and spare parts readily available is a great start to being proactive and maintaining effective system operation, but what if you could catch a potential issue before it becomes one? Whether it is still on the drawing boards or has been on site for years, your air pollution control system represents a significant investment and a long-term commitment to environmental compliance. A well-crafted maintenance plan for your oxidizer will allow you to get the most from your investment over the entire life of the system.

The Solution

Many will come to this article hoping for a one-size-fits-all checklist for maintaining an oxidizer system. As a company that offers service on any oxidizer regardless of style or original manufacturer, we at Anguil have long wanted the same. A set recipe for success would certainly make life easier. For those in need of a quick answer or a starting point from which to grow, we do not wish to disappoint. Absent of knowing anything else about the operating context of a particular oxidizer system, our best recommendation for a basic maintenance plan is as follows:

service on any oxidizer regardless of style or original manufacturer, we at Anguil have long wanted the same. A set recipe for success would certainly make life easier. For those in need of a quick answer or a starting point from which to grow, we do not wish to disappoint. Absent of knowing anything else about the operating context of a particular oxidizer system, our best recommendation for a basic maintenance plan is as follows:

- Gather all the system documentation as listed in Part 1 of our Oxidizer Service Series. Make sure this documentation is readily available to both system operators and service providers.

- Stock the recommended spare parts for your oxidizer system (more on this in Part 3 of our Oxidizer Service Series)

- Establish a monthly checklist of system inspection points and make sure your own operators are comfortable with what to look for and how to record their findings

- Maintain an operator log book or journal of system issues

- Obtain a yearly Preventive Maintenance Evaluation (PME) from an independent or third party oxidizer service provider such as Anguil

- Establish remote access capability to your system’s controls from an oxidizer service provider such as Anguil

Some may choose to take this basic recommendation for a maintenance plan, stop reading here, and run with it. We would agree that anyone complying with all of the steps as outlined above is indeed making a defensible effort at maintaining their oxidizer system; however, having an Oxidizer Service Provider like Anguil visit your site for a couple days could jump-start the implementation of such a plan.

Maintenance Plan Drivers

The following drivers make the decision to implement an oxidizer maintenance plan imperative:

Production Uptime – An informed staff and a transparent maintenance plan will allow for maximum production uptime, prevent costly shutdowns, and enable a prepared response to operational irregularities.

Compliance with Environmental Regulations – Being out of compliance can be costly and a public relations disaster. The language in many air permits requires operators to stock spare parts, keep historical service documentation, and maintain the system according to the manufacturer’s recommendations.

Compliance with Safety Regulations – Compliance codes often require that safety checks be performed on an annual basis for this class of equipment. Anguil incorporates these safety checks as a part of our 75+ point Preventative Maintenance Evaluation.

Operating Cost Reduction – A good maintenance plan will often pay for itself by ensuring that your oxidizer system is running at peak efficiency and with minimal downtime.

Maintenance Plan Building Blocks

The right maintenance plan for one company might not be the right plan for another. Anguil considers the following to be the building blocks of a comprehensive maintenance plan that can be customized to fit the needs of any operating context.

- System Documentation – Gather all your system documentation in one binder as outlined in Part 1 of our Oxidizer Service Series. Make sure this documentation is readily available to both system operators and service providers. We recommend storing

inside the control panel.

inside the control panel. - Recommended Spare Parts Package – An Oxidizer Service Provider like Anguil can identify the critical components, recommended components, and convenience items that you should stock to maintain smooth operation of your system and limit production down time.

- Annual Preventive Maintenance Evaluation (PME) – Often done by an Oxidizer Service Provider like Anguil. This is not just our advice. This is rapidly becoming part of Permit Codes and Compliance – both environmental codes and safety codes. Anguil’s standard PME program includes a 2-3 day service visit utilizing a 75+ point checklist to ensure your oxidizer is meeting air pollution control standards and is followed by a formal report for your maintenance records.

The next four options can be performed in conjunction with a PME visit or ordered separately as stand-alone services.

- Destruction Removal Efficiency (DRE) Check-Ups – An oxidizer service provider like Anguil can check the VOC destruction efficiency of your system with portable testing equipment or via laboratory analysis of air samples. This service keeps you on track with system performance and verifies compliance. It is ideal as a pre-test to help eliminate “surprises” during expensive formal compliance testing.

- Repeat Operator Training – Maintenance personnel take pride in servicing the equipment if they are familiar with the operation. Years one and two of an oxidizer’s life can present different maintenance challenges than years three through fifteen. Repeat training can keep operating personnel prepared to meet evolving service needs. Repeat Operator Training is showing up in the NFPA codes as well.

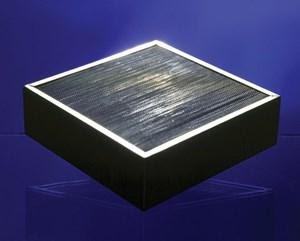

- Catalyst Services – At the heart of every Catalytic Oxidizer System is the catalyst bed. Properly maintained, the catalyst bed can provide years of high VOC Destruction at temperatures well under those required for thermal oxidation. Anguil offers a full program of catalyst services including Evaluation and Testing, Rejuvenation, Replacement, and the purchase back of “spent” catalyst for recycling.

- Split Preventative Maintenance Evaluations – Some facilities have little precious downtime for system repairs, so they want to be prepared with the right parts and contractors to act on repairs immediately when their downtime occurs. They may elect a Split-PME scenario, which starts with a one day system evaluation visit by a Field Service Engineer. A second visit is scheduled and the Field Service Engineer returns with all parts and materials identified in the system evaluation, prepared to execute on the service recommendations immediately.

- Semi-Annual Preventative Maintenance Evaluations – For some, the yearly comprehensive Preventive Maintenance Evaluation is not enough. Overall system balancing, operational cost verification, and inventory of spare parts should be conducted semi-annually. Depending on the complexity of your system, you may wish to contact Anguil to perform this service for you.

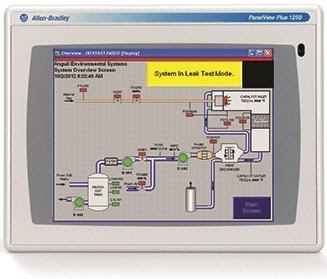

- Remote Login Capability – Remote log-in could be your lifeline in emergency situations. Establishing this capability is one of the most important things you can do when devising your maintenance plan. Remote Access Capability has recently become a game changer in the oxidizer service world. For the companies and oxidizer systems we service, when the capability is in place, it is both a lifeline during system upsets as well as a “force-multiplier” when our Field Service Engineers are on a particular site. One need only walk into our Service Manager’s office during a live-connection event and see two or three additional heads observing the system operation in real-time while conversing directly with our Field Service Engineer on site. It is akin to getting the experience and knowledge of several engineers on site for the price of one. In today’s world, no oxidizer end-user should be left behind without this critical safety net in place. Don’t wait for an emergency to find out the connection isn’t there. Anguil can also perform routine operational checks remotely and potentially identify developing service issues proactively for a fraction of the cost of an on site visit. Adding this service quarterly is rapidly becoming a popular option. For those with this feature, make sure to regularly test your connection.

- Operating Cost Review – Do you know exactly how much your system should be costing you to run? Are you getting the most for your operating dollars? Anguil offers an Operating Cost Review Program that can answer these questions for you and provide cost savings recommendations tailored for your oxidizer system.

- Operator Log Book – Thorough service history documentation, including a historical account of daily, weekly, and annual inspections, is often an air permit requirement. Like a doctor’s medical records, a comprehensive operator log will help diagnose operating irregularities and could prevent costly malfunctions down the road.

- Weekly Walk-By Inspections – Typically performed by your own personnel. An Oxidizer Service Provider like Anguil can custom design weekly inspection checklists for your specific oxidizer system.

- Deeper Monthly/Maintenance Day Inspection Checklists – For our Monthly Inspections program, we provide a list of the system components needing inspection, independent verification, and/or calibration on a monthly basis. Our goal is to train your maintenance teams to feel comfortable performing the monthly checks on their own.

- Custom Maintenance Plans – Multi-Year and Multi-Facility Packages

- Developing a custom maintenance plan with an Oxidizer Service Provider can result in a strong service relationship built on trust and long-term oxidizer expertise. Anguil’s custom maintenance plans include multi-year deals for individual plants or across multiple facilities. Custom multi-year and multi-facility maintenance plans can offer numerous benefits:

- Smooth Equipment Turnover Between Project Engineering and Production Engineering Teams – Many oxidizer systems are purchased via a project engineering team who then must turn the equipment over to production teams. This hand-off can proceed much smoother if the production team sees that there is a service agreement already in place.

- Reliable Budgeting – Having a multi-year service plan can take some guesswork out of operational budgeting.

- Consistent Service History – even as plant personnel may turn over.

- Knowledge Sharing – Maintaining service history at the plant level can be difficult enough. A corporate level maintenance plan can become a conduit for improved knowledge sharing between plants.

- Uphold Corporate Values – Environmental Compliance is often part of your Corporate Level Mission Statement.

Reliability Centered Maintenance

Anguil recently participated in a three-week-long Reliability Centered Maintenance (RCM) evaluation of an oxidizer system. This particular system treats the exhaust from a critical production line in one of the most highly regulated areas of the country. RCM is a landmark maintenance concept defined in John Moubray’s book Reliability-Centered Maintenance as “a process used to determine the maintenance requirements of any physical asset in its operating context.”

For this RCM evaluation, a team of Anguil Personnel along with the facility’s maintenance personnel, equipment operators, electrical controls specialists, and EHS staff was assembled and guided by an RCM facilitator. The team went line-by-line through the oxidizer electrical schematics, the sequence of operation, the control programs and the environmental permit requirements to define the system’s functions and possible functional failures. Using the framework of the RCM program, the team generated lists of potential redesigns, required procedures, a compulsory spare parts program, and implementation reports for the system as a whole. This was no small task — the final report was over 400 pages long! The evaluation was a significant investment in both money and manpower for both Anguil and the company involved.

Our two biggest takeaways from this experience were:

- This is the level of training that operators of oxidizer systems deserve but rarely get

- The importance of “Operating Context” in determining a suitable approach to long term maintenance of a particular oxidizer system

To further illustrate the idea of operating context, consider that oxidizers today are being installed into production scenarios where they:

- May be allowed to be offline for several weeks or months in a given year

- May force the end-user to stop all production immediately when offline, in some cases triggering “Notices of Violation” and fines upon any upset condition

- May be treating exhaust gas streams that are immediately dangerous to life and health

- May be the sole source of heat for the process to which they are attached

Each one of these different operating contexts can play a major role in the final determination of an appropriate maintenance plan for a particular oxidizer system.

Not everyone can afford to go to the lengths of implementing a formal RCM maintenance program for their oxidizer system. There are also plenty of industries with enough historically acquired experience where such an effort may not be required. However, an effective and custom maintenance plan adhering to minimum requirements can be crafted with help from an Oxidizer Service Company like Anguil and customized to your particular operating context. Such a program will prolong the life of your equipment while staying within the restraints of an operating budget.

The Result

In summary, there is no one-size-fits-all solution for crafting a quality oxidizer safety and maintenance program. At Anguil, we strive to offer a full menu of reliability services to make crafting even the most basic maintenance plan an essential and affordable investment. Our experienced service personnel look forward to assisting you in designing the smartest maintenance program for your company.

This is the second of four parts in Anguil’s Oxidizer Service Series. We encourage you to also view Part 1: Better Maintenance Starts With Better Documentation as well as Part 3: Stocking Spare Parts for Your Oxidizer System and Part 4: Oxidizer System Optimization.

Catalytic Oxidizer Catalyst Replacement

Comments Off on Catalytic Oxidizer Catalyst Replacement The Challenge

The Challenge

A New Jersey pharmaceutical company purchased a thermal incinerator to treat the heptane and hexane exhaust from their capsule wash system. The thermal incinerator’s “tubular” design was modified with a catalyst bed in order to reduce the system’s operational costs. Unfortunately, when operating in the catalytic mode, the oxidizer failed to provide the required 95% destruction efficiency of non-methane hydrocarbons required by the New Jersey Department of Environmental Protection. These odorous emissions led to neighbor complaints and an EPA consent decree, complete with a $175,000 civil penalty. Although the company was proactive in trying to solve the emission problem, the EPA stipulated penalties of $2,500 for every day the violation existed. The original equipment supplier attempted to rectify the problem to no avail and the pharmaceutical company remained in violation of their New Jersey air permit.

The Solution

After meeting with several potential suppliers, the company selected was Anguil Environmental Systems, Inc. Anguil’s track record with catalytic systems, knowledge of catalyst and engineering strength made them the most likely candidate to tackle the VOC problem successfully.

The Result

The Result

Anguil successfully retrofitted the non-compliant system and brought the company into EPA compliance. The first step in Anguil’s approach was to examine the reason for catalyst nonperformance. There were several potential reasons for catalyst failure. The possibility of catalyst masking or the presence of a poisoning agent (i.e. sulfur, phosphorus, heavy metals) within the VOC-laden stream was examined; however, no significant levels of any of these agents were detected.

The second possibility was that the industrial process stream was being allowed to pass through the oxidizer before it was brought to proper operating temperature. This would result in the coating of the stainless steel rings with the heptane and hexane hydrocarbons. If this was the case, when the unit was brought to the proper operating temperature, oxidation would occur on the catalyst, leaving a carbon deposit. This type of carbon deposit would result in decreased destruction efficiency and the formation of incomplete combustion products. No signs of these carbon deposits, known as coking, were detected.

Having eliminated these suspects, Anguil conducted a laboratory performance test that indicated the reason for catalyst failure: the catalytic stainless steel rings lacked the proper surface area to achieve the quoted destruction efficiency. This performance test revealed that there was less than 50% destruction efficiency of a propane and propylene test stream. This is an excellent indicator of catalyst failure or inactivity.

Anguil modified the system design to accommodate a honeycomb catalyst. The monolithic catalyst Anguil chose was a 300 cell-per-square-inch ceramic substrate. An alumina washout was used to deposit large quantities of precious metal (i.e. platinum, palladium, rhodium). The surface area of this replacement catalyst is more than 100 times greater than that of its stainless steel counterpart. (Note: a cubic foot of this monolithic catalyst contains more surface area than that of a football field.) The oxidizer was equipped with a new reactor section to house the nine cubic feet of monolithic catalyst. A 95% destruction efficiency guarantee was provided along with the system retrofit.

A follow-up Flame Ionization Detector (FID) was also performed on this retrofit and a carbon filter was added to eliminate methane readings. The FID test results indicated a VOC inlet concentration of 943 ppm and an oxidizer outlet concentration of less than 20 ppm. The company is now EPA-compliant 97.8% destruction efficiency. Anguil is well-known for providing VOC control systems but in this case, they demonstrated their ability to provide answers where others had failed.

Better Maintenance Starts with Better Documentation

Comments Off on Better Maintenance Starts with Better DocumentationThe Challenge

OXIDIZER SERVICE SERIES: PART 1

Part of properly servicing your oxidizer system is maintaining the design documentation associated with that system. When it comes to oxidizer design, National Fire Protection Association (NFPA) standards are considered good practice, and those same standards include requirements that should be used for ongoing oxidizer maintenance and system documentation.

The Solution

The following are critical design documents oxidizer users should preserve that contain information required by the NFPA to implement an overall system reliability plan. Anguil uses the same documents to build and maintain information to offer value-added service on anyone’s oxidizer system, regardless of the original manufacturer. The documents listed with an asterisk (*) are the three most important documents to have on hand and you should always have print copies inside your control panel.

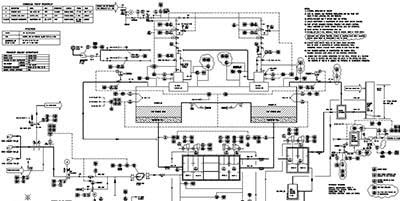

- Process and Instrumentation Diagram (P&ID):The P&ID is the command drawing that summarizes instrumentation, safety devices, operational limits, and control loops. The P&ID typically provides the oxidizer component tag numbers, as well as the number and type of process exhaust pick-ups for the system. The system utility requirements and performance parameters can be listed as well.

- Electrical Schematics:The electrical schematics provide the detailed connectivity of the entire system and is an important tool used for system troubleshooting. It is critical that the electrical schematics are not only kept readily available, but also revised to keep up with system changes.

- Sequence of Operation / List of Set Points & Alarm Conditions:The sequence of operation is a step-by-step description of how the oxidizer is designed to operate. It includes: how it starts, how it brings process exhausts on-line, how it maintains airflow and temperature control, and how it safely shuts down. Set points and alarm conditions of the system are also included in this document. It is important to note that this documentation is required per the National Fire Protection Association’s NFPA 86: “Wiring diagrams and sequence of operations for all safety controls shall be provided” (From NFPA 86: Standard for Ovens and Furnaces, 2019 Edition – Section 4.1.1.2).

- Programmable Logic Controller (PLC) Program: If your system requires a PLC, we recommend you keep a fully documented copy of your PLC program for your records. It is important to know that some oxidizer suppliers may be reluctant to release this information to system end-users because PLC programs can include proprietary control schemes. However, with a signed confidentiality agreement in place, end users should be able to obtain this code. If your oxidizer manufacturer is no longer in business, it is possible to upload the program directly from the PLC, but it may be undocumented and you may need an oxidizer service provider to re-enter the code documentation. Information on Anguil’s PLC programming capabilities can be found here.

- Human Machine Interface (HMI) Program:The HMI (Operator Interface / Operator Touch Screen) is the operator’s window into the workings of the oxidizer’s PLC. The HMI program goes hand-in-hand with the PLC program to control your oxidizer system by displaying data points from the PLC along with set points and tuning parameters the operator will be allowed to adjust from the HMI. The HMI also provides system status messages and/or alarm messages based on the PLCs outputs. A failed display can leave you essentially blind when it comes to operating your oxidizer system safely. If this happens at an inopportune moment, you want to be prepared to download your HMI program to a replacement display from your spare parts inventory.

- Expected Pressure-Temperature Profile:This is one of the more obscure documents to obtain, however, it is pivotal in the development of a reliability plan for your system. Obtaining this information can be as simple as a small table on the P&ID giving the expected temperature and pressure value at various points throughout the oxidizer. It is critical to know your pressure point values in order to set up a regular inspection plan for your maintenance personnel. Ideally, you should have a table showing expected pressure and temperature data at the common process exhaust airflow amounts your production requires. If this is unknown, ask your system provider to provide data for two conditions: at full-oxidizer airflow capacity and at half-oxidizer airflow capacity. Once provided this information, you will be able to approximate the points in-between when establishing your customized inspection checklists.

- Permit Compliance Documents:Compliance documentation requirements vary greatly across local, state, and federal agencies, making it difficult to provide generalized recommendations appropriate for all operation scenarios. At a minimum, Anguil highly recommends summarizing your permit compliance documentation requirements within a single, concise document that includes minimum and operating temperatures and bypass limitations. This document will keep all parties aware of the key compliance parameters to monitor and record with respect to your oxidizer system.

- Bill of Materials / Recommended Spare Parts Lists:Finally, a complete bill of materials for your oxidizer system will allow you to obtain the parts you need to maintain system operation. Ideally, the parts listed in the Bill of Materials would be further categorized as “Critical Spare Parts,” “Recommended Spare Parts,” “Consumable Spare Parts,” “Convenience Items,” “Long Lead Time Components,” etc. This allows operators to make an informed decision on the type and quantity of spare parts to stock based on specific production and compliance requirements. Some air permits actually require that critical spare parts be kept on hand. More detailed information on these categories can be found on the Spare Parts section of our website.

ADDITIONAL INFORMATION

ADDITIONAL INFORMATION

Here are some additional highlights regarding system documentation from the current edition of NFPA 86 Standard for Ovens and Furnaces 2019 Edition:

4.1.1.1 Plans shall be drawn that show all essential details with regard to location, construction, ventilation, piping, and electrical safety equipment. A list of all combustion, control, and safety equipment giving manufacturer and type number shall be included.

4.1.1.2 Wiring diagrams and sequence of operations for all safety controls shall be included.

7.3.3 Operating instructions that include all of the following shall be provided:

(1) Schematic piping / wiring diagrams

(2) Startup procedures

(3) Shutdown procedures

(4) Emergency procedures

(5) Maintenance procedures

7.3.4 When the original equipment manufacturer no longer exists, the user shall develop inspection, testing, and maintenance procedures.

The Result

This is the first of four parts in Anguil’s Oxidizer Service Series. We encourage you to also view Part 2: Crafting Your Oxidizer Maintenance Plan as well as Part 3: Stocking Spare Parts for Your Oxidizer System and Part 4: Oxidizer System Optimization.

A Media Replacement Emergency

Comments Off on A Media Replacement Emergency The Challenge

The Challenge

Anguil Environmental Systems recently completed an emergency media replacement on two Megtec Cleanswitch Regenerative Thermal Oxidizers (RTOs) for a world-wide automobile supplier.

The Solution

Both systems were 65,000 SCFM (104,325 Nm3/hr) units and built by another supplier approximately 10 years ago for two different automotive facilities in the United States.

Anguil was chosen to replace the RTO media for this world-wide automobile supplier over the original supplier based on its competitive pricing and timely responsiveness.

The Result

One of the RTOs was extremely difficult to access being located on a three-story roof and a considerable distance away from the building’s exterior wall. Replacement of the media required removal of the upper half of the RTO and use of a high lift crane to accommodate the heights and distances involved.

At the other facility where production uptime was critical, Anguil’s crew worked double shifts to complete the work over a weekend so that the production was not affected.

Anguil completed the projects early and under budget due to proper planning and customer communication.