Many industrial processes produce emissions that must be neutralized before they can be safely released into the environment. Thermal and catalytic oxidizers are technologies that perform this crucial operation in many industrial air pollution control applications. Rotary concentrators are an add-on technology that enhances the efficiency and effectiveness of these oxidation processes. This blog explores rotary emission concentrators, including their applications, features, and benefits.

Many industrial processes produce emissions that must be neutralized before they can be safely released into the environment. Thermal and catalytic oxidizers are technologies that perform this crucial operation in many industrial air pollution control applications. Rotary concentrators are an add-on technology that enhances the efficiency and effectiveness of these oxidation processes. This blog explores rotary emission concentrators, including their applications, features, and benefits.

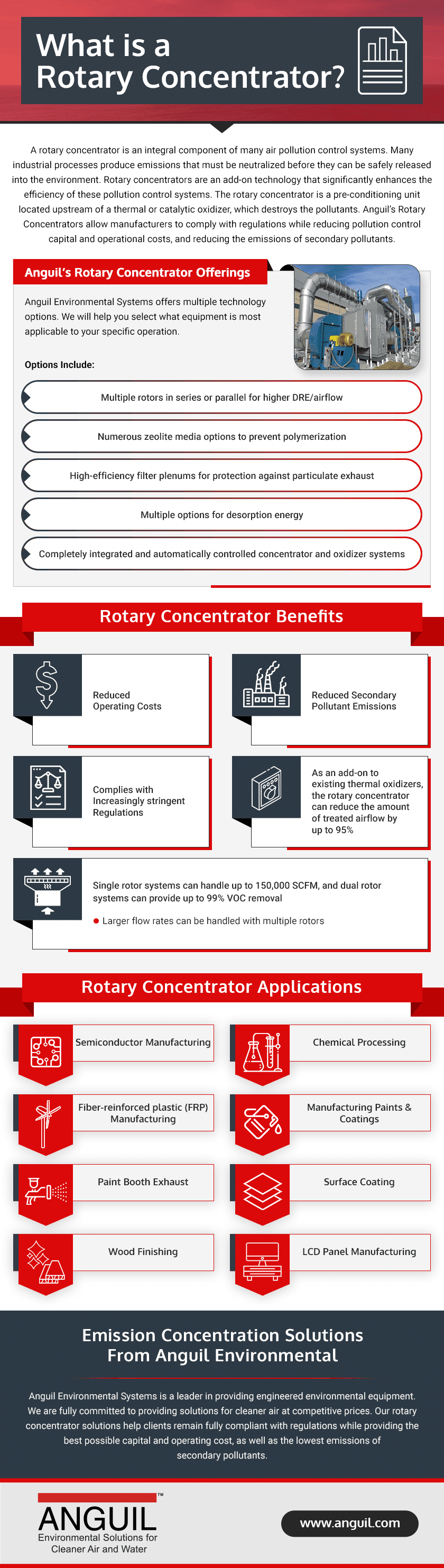

Emission Concentrator Overview

A rotary concentrator is an air pollution control system that converts large volumes of air with low concentrations of solvents or volatile organic compounds (VOCs) into small-volume, high-concentration airstreams. The rotary concentrator is a front-end, pre-conditioning unit located upstream of a thermal or catalytic oxidizer, which destroys the pollutants. A smaller oxidizer can be used since the VOCs are concentrated from a large airstream into a smaller airstream, saving on fuel auxiliary energy, and space.

The most significant benefit of using a rotary concentrator in conjunction with an oxidizer is reduced operating costs. This comes from providing a much richer airstream to the combustion device that acts as fuel, saving on operating costs. Rotary concentrators also eliminate the need for larger oxidizer systems, which allows for more efficient space management. The smaller-sized oxidizer also reduces the capital costs of the combustion device. Manufacturers can avoid unnecessary expenses while making space for production growth.

How Do Rotary Emission Concentrators Work?

The low-concentration, high-volume airstream first passes through the rotary concentrator, where VOC emissions are stripped away from the air and adsorbed onto the zeolite media. At this point, the process air is about 90-99% clean and exhausted into the atmosphere. Removal efficiencies from the rotor vary on the emission constituents. To increase efficiency at this stage, additional rotors can be put in series upstream of the oxidizer.

Spinning continuously at a slow rate, the concentrator wheel is comprised of two sections; absorption and desorption. As air passes through the Adsorption section, VOCs at normal temperatures will attach to the zeolite wheel while the clean air goes directly into the atmosphere. A small portion of the contaminated air is heated to elevated temperatures and used to desorb those VOCs from the wheel in the desorption section. The desorbed VOCs are in a much smaller airflow; roughly 5-10% of the original flow, and sent to the downstream oxidizer for final VOC destruction.

Rotary Concentrator Applications

Rotary concentrator systems work great for high-volume air streams with low VOC concentrations, ideally below 500 ppmv and when temperatures are below 100 °F.

Common applications include:

- Semiconductor manufacturing

- Chemical processing

- Fiber-reinforced plastic (FRP) manufacturing

- Manufacturing paints & coatings

- Paint Booth Overspray

- Surface coating

- Wood finishing

- LCD panel manufacturing

Rotary Concentrator Features & Benefits

Using an oxidizer in conjunction with a rotary concentrator is typically the most cost-effective solution when dealing with low-concentration, high-volume airstreams. Its upfront cost may be similar, if not less, than an oxidizer designed at full flow capacity. The real benefit of the concentrator is the reduced operational costs and secondary pollutant emissions. A paired concentrator/oxidizer uses much less auxiliary energy because the much smaller airflow being sent to the oxidizer has more thermal energy in the concentrated stream.

Regulations are increasingly mandating higher VOC control efficiencies. With most air pollution control systems focusing on inert VOC and destruction equipment, combustion devices must be able to handle larger volumes of air with lower VOC concentrations, and this machinery can be expensive. The Anguil rotary concentrator allows manufacturers to remain compliant with these regulations, save money and energy, and increase efficiency. As an add-on to existing thermal oxidizers, the rotary concentrator can reduce the amount of treated airflow by up to 95%.

Since oxidizers are designed for specific projects according to maximum airflow, manufacturers can save a significant amount of capital costs. Single rotor systems can handle up to 150,000 SCFM with multiple stages of zeolite reaching up to 99% VOC removal. Larger flow rates can be handled with multiple rotors in parallel.

Rotary Concentrator Options

Anguil Environmental Systems offers multiple technology options for destroying hazardous air pollutants, VOCs, and odors. We can help you select the most applicable equipment for your manufacturing operation. Our consultative approach with clients ensures they receive the best possible solution for the abatement objectives so you receive the best possible solution for your specific needs. Our options include:

- Multiple rotors in series or parallel for higher DRE/airflow

- Numerous zeolite media options to prevent polymerization

- High-efficiency filter plenums for protection against particulate exhaust

- Multiple options for desorption of air heat

- Completely integrated and automatically controlled concentrator and oxidizer systems

Emission Concentration Solutions From Anguil Environmental

Anguil Environmental Systems is a leader in providing engineered environmental equipment. We are fully committed to providing solutions for cleaner air at competitive prices. Our rotary concentrator solutions help clients remain fully compliant with regulations while providing the best possible capital and operating cost, as well as the lowest emissions of secondary pollutants. More information can be found on the Rotor Concentrator page.

At Anguil, we believe in clean water and air. Public health, sustainability, and economic prosperity are interconnected, and we are committed to promoting these values together. To learn more about how we can help your business with emission concentration, contact us today.

Comments are closed