Committed to Cleaner Air with Quality Abatement Technologies.

At Anguil Environmental Systems, our team is fully committed to ensuring a cleaner environment for future generations.

Clean air from industry is essential for the safety of onsite staff and neighboring communities while ensuring a socially responsible operation. Air pollution can occur when toxic or hazardous contaminants in gaseous, liquid, or particulate form are released from a manufacturing process. If the concentrations are sustained for a long enough period of time, they can pose real health risks for workers and those in the surrounding areas, create safety hazards, and result in non-compliance with local or federal regulations.

Industrial regulatory bodies establish strict standards that provide guidelines for maintaining air quality at industrial and manufacturing facilities. As is the case with many industrial manufacturing operations, emissions are best destroyed through the use of thermal of catalytic oxidation via high high-temperature combustion. These systems help keep your organization in compliance, achieve environmental, social, and governance (ESG) initiatives, manage increased regulatory standards and enforcement norms, and meet the environmental expectations of your community and customers.

Industrial Air Pollution Control: How It’s Done

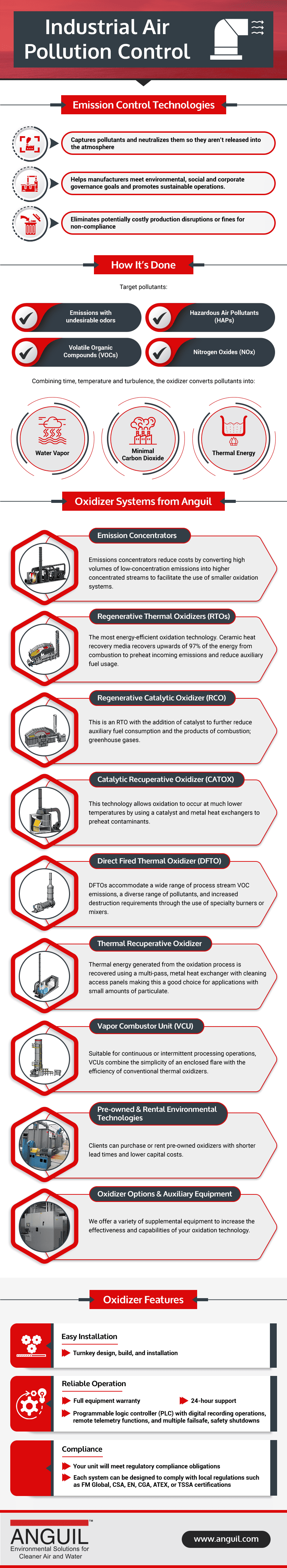

At their core, industrial air pollution control technologies capture pollutants and neutralize them so they aren’t released into the atmosphere. This two-step focus both reduces organizations’ emission footprints and eliminates potentially costly production disruptions or fines for non-compliance. We provide a comprehensive suite of thermal and catalytic oxidizer units that can provide this service. First, the units intake pollutants such as:

- Hazardous Air Pollutants (HAPs)

- Volatile Organic Compounds (VOCs)

- Nitrogen Oxides (NOx)

- Emissions with undesirable odors

Oxidation technologies use time, temperature and turbulence to convert the pollutants into water vapor, carbon dioxide, and thermal energy. Every abatement system is designed to provide reliable, energy-efficient performance based on the unique needs and output of your facility. Our full offering of technologies allows Anguil to evaluate each application and recommend the best solution based on performance requirements and efficiency needs, without prejudice.

Industrial Air Pollution Control Technologies

Anguil oxidizer technologies are designed around customer’s destruction requirements, efficiency needs, and process parameters. The depth of our offering ensures an unbiased equipment selection.

- Regenerative Thermal Oxidizers (RTOs): This is the most energy-efficient and cost-effective abatement (pollution reduction) technology. In this method, thermal energy is recovered and reused to reduce emissions.

- Catalytic Recuperative Oxidizer (CATOX): This method allows oxidation to occur at much lower temperatures by using a catalyst and heat exchangers to preheat contaminants.

- Direct Fired Thermal Oxidizer (DFTO): DFTOs accommodate highly concentrated emission streams, a diverse range of pollutants, and increased destruction requirements through the use of specialty burners.

- Thermal Recuperative Oxidizer: Thermal energy generated from the oxidation process is recovered using a multi-pass, metal heat exchanger.

- Vapor Combustor Unit (VCU): Suitable for continuous or intermittent processing operations, VCUs combines the simplicity of an enclosed flare with the efficiency a conventional thermal oxidizer.

- Emission Concentrators: Emissions concentrators reduce costs by converting high volumes of low-concentration emissions into higher concentrated streams to facilitate the use of smaller destruction devices.

- Pre-owned & Rental Environmental Technologies: Our clients can purchase or rent pre-owned or refurbished oxidizers with a full warranty.

- Auxiliary Equipment: We offer a variety of supplemental equipment to increase the effectiveness and capabilities of your oxidation technology.

Thermal and Catalytic Oxidizer Features & Benefits

Each Anguil oxidizer has these key advantages and we offer multiple options for optimization:

- Easy installation: We offer turnkey design, build, and installation services, which include the unit and all ductwork and utility components. Units are pre-assembled and tested at our factory for easy integration with your existing systems.

- Simple Operation: Each unit includes a full equipment warranty and 24-hour support, and it won’t require expensive replacement parts. All units include a programmable logic controller (PLC) for easy, automated management with digital recording operations, remote telemetry functions, and multiple failsafe and safety shutdowns for guaranteed safety.

- Compliance: Your unit will meet regulatory compliance obligations, and each gas train can be designed to comply with FM Global, CSA, EN, CGA, ATEX, or TSSA certifications.

Industrial Air Pollution Control Systems From Anguil Environmental

Clean air is our top priority, and we’re here to help you meet and exceed environmental regulatory standards and your organization’s ESG objectives. Air pollution control encompasses the systems, techniques, and practices your organization uses to reduce emissions, increase air quality, and otherwise limit harm to the environment and humans. The first step to crafting an effective industrial air pollution control process is to evaluate your current emissions or air quality and compare them to your compliance requirements so you can set measurable emission control objectives.

At Anguil Environmental Systems, Inc., we specialize in stationary industrial air pollution control systems that capture and destroy off-gas emissions and ultimately help your facility and help your facility reach its ESG and emissions objectives. Process equipment such as dryers, coaters, ovens, laminators, mixers, and paint booths are the primary stationary emission and odor sources at industrial manufacturing facilities. These off-gases can be solvents from glues, paints, and coatings used in production or emissions like ethanol that are naturally emitted from corn distilling, bread baking or alcohol fermentation. We assess emission constituents, concentrations, flow, and temperature to determine the scale of emissions and which pollution control technology should be employed to capture, control and destroy the present contaminants.

Contact us today to learn more about our industrial air pollution control systems or speak with an expert about your unique needs.