A Fossil Fuel Free Solution

Comments Off on A Fossil Fuel Free SolutionThe Challenge

As individuals and corporations continue to push towards smaller carbon footprints, the use of Lithium-Ion Batteries (LIB) has become increasingly prevalent. Specifically for individuals, the utilization of battery packs for all-electric automobiles and solar-powered home battery banks have continued to grow at a rapid rate. The manufacturing of these battery packs generates several air pollutants that must

One large supplier of LIBs faced a unique set of challenges at their main production facility.

- Three identical abatement systems were required, capable of handling up to 35,000 SCFM of emission laden air each. Electrically heated air pollution control systems are typically much smaller.

- Fossil fuels (natural gas, propane, fuel oil, diesel, etc.) of any kind are not allowed in the factory.

- Process gases consist of both ambient and hot air streams, both with very low concentrations.

- All abatement systems were to be installed indoors on the third floor of the factory with very tight footprint and height constraints.

Manufacturing of complete LIBs requires several different processes and operations that produce Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs) at varying temperatures. For instance, making battery electrodes uses N-Methyl Pyrrolidone (NMP) which is a solvent the manufacturer can recover and reuse without treatment in a pollution control device. However, this supplier had additional module manufacturing lines and multiple e-coat paint lines with curing ovens where solvent recovery was not an option. This further complicated the compliance solution.

The Solution

Anguil was tasked with developing a compliance solution to capture and treat 70,000 SCFM of emission laden air with the following requirements:

- Achieve a minimum 90% overall air pollutant reduction

- Any heating requirements must be achieved without the use of any fossil fuel

- Provide an n+1 arrangement for system redundancy during maintenance

- Minimize all utility consumption to the greatest extent possible

- Reduce overall system footprint, height, and weight to fit within facility restraints

Anguil is one of the few industrial air pollution control providers that offers a full line of thermal and catalytic oxidizer technologies that also includes emission concentrators. The diverse technology offering allowed Anguil to evaluate each option and its applicability for the demanding project objectives.

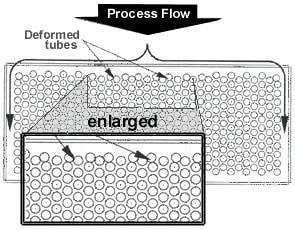

The first decision was to route all ambient process air sources to a zeolite concentrator wheel. The wheel uses a zeolite substrate to adsorb the VOCs and HAPs out of the process gases and onto the concentrator surface. A heated stream, approximately 10% the original volume, is used to desorb the pollutants from the wheel. The result is a highly concentrated stream that is one-tenth the original volume. This significantly reduces the size, capital and operating costs of the downstream oxidizers that are paired with the concentrator wheel.

Anguil engineers made the decision to utilize Regenerative Catalytic Oxidizers (RCO) with electric heating elements to treat both the hot process stream from their curing ovens and the concentrated air stream from the concentrator wheel. This technology combination is often referred to as an RCTO. Employing catalyst inside a thermal oxidizer allows emission destruction to occur at much lower temperatures; 600-800°F (315-427°C) versus 1,400-1,500 °F (760-816°C). The lower operating temperature also provides for a much more reliable and smaller (physical size and KW rating) electric heating element. The RCO uses ceramic blocks as the heat transfer media

All three oxidizer systems and the concentrator wheel were to be installed inside on the 3rd floor of a building still under construction under an existing mezzanine that provided only 15’ of overhead clearance. Anguil designed all individual pieces so they could be lifted three stories using an external elevator and fit through a narrow overhead door. All three units were installed inline and connected via common inlet and outlet manifolds to reduce installation costs.

Once installation was complete, Anguil’s start-up technicians arrived onsite to complete final commissioning. Anguil’s technicians conducted operator training consisting of both “on skid” and classroom sessions. Test data has shown each of the systems is achieving greater than 90% overall emission removal and 97% TER.

The Result

- Anguil was able to listen to the customer’s needs and the unique requirements of an oxidizer system that can process up to 70,000 SCFM of VOC-laden air without the use of fossil fuels.

- The zeolite concentrator wheel was applied to the ambient temperature sources, greatly reducing the size of the downstream oxidizers and the associated utility requirements.

- Selecting an electrically heated RCO eliminates the need for a fossil fuel fired burner, a customer requirement. The use of catalyst allows the oxidizer to operate at a much lower temperature than a thermal oxidizer, minimizing the size of the electric heating element. The RCO was also designed with 97% TER, further reducing the utility requirements and the size of the heating element.

- The hot source from the cure oven was sent directly to the RCO inlet, having no negative impact on the operation and efficiency of the concentrator wheel.

- Supplying three identical systems each sized to process 35,000 SCFM allows the customer to process up to 70,000 SCFM of VOC-laden air while operating in the required n+1 arrangement.

- Each system was designed to minimize the footprint and height to the greatest extent possible, saving on valuable floor space inside the facility.

- The system efficiency and effectiveness have exceeded the design specifications.

Heat Exchanger Retrofit

Comments Off on Heat Exchanger Retrofit The Challenge

The Challenge

A manufacturer of insulation films for the electronics industry needed to evaluate the capabilities of four existing oxidizers that treated emissions from its coating lines. The company was concerned that, due to oxidizer deficiencies, it would not meet regulatory requirements. The oxidizers had been manufactured by two different companies. One of them was no longer in business and the other was unable to provide an adequate solution. The customer needed an experienced engineering company that could accurately identify the oxidizers’ deficiencies and provide quality repairs.

The Solution

After evaluating the service capabilities of several equipment manufacturers and engineering consultants, the company chose the full-service solution of Anguil Environmental Systems. Anguil’s comprehensive preventive maintenance evaluations of the four oxidizers provided detailed recommendations to improve the oxidizers’ performance. The most urgent recommendation saved the company thousands of dollars in operating costs and put the company in compliance.

The Result

Anguil’s rigorous 75-point Preventive Maintenance Evaluation (PME) discovered minor problems with three of the units and a major problem with the largest oxidizer, a 13,500 SCFM (21667.5 Nm3/hr) catalytic oxidizer. Anguil’s recommendations for the three smaller oxidizers greatly improved their safety and performance. Many of the cost-saving suggestions were easily performed by the plant’s in-house maintenance staff. However, the larger oxidizer required more intensive application engineering and a comprehensive air pollution control solution.

The 13,500 SCFM (21667.5 Nm3/hr) system had both a primary and secondary heat exchanger. The primary heat exchanger recovers energy from the combustion chamber exhaust and transfers it to the incoming process air stream to reduce fuel consumption. The secondary heat exchanger recovers additional energy from the primary heat exchanger outlet flow and uses this energy to preheat an air source used in the process. In this case, the secondary heat exchanger is integral to the plant’s coating process; it is used to heat the tower dryer of the AISCO coating machine. The plant engineers had noticed a steady decline in the heat available from the oxidizer and secondary heat exchanger. By the time of Anguil’s investigation, the oxidizer took up to six hours to sufficiently heat the coater before production could begin. During the six hours of warm-up, the oxidizer had to be supplied with natural gas. This tremendous fuel consumption led to extremely high operating costs.

Anguil performed a destruction efficiency test on the oxidizer when the coated web used 100% toluene as a solvent. Under normal conditions, an oxidizer of this type should have little difficulty in attaining better than 98% destruction efficiency. Due to the airflow bypassing the combustion chamber, the oxidizer was achieving only 93.6% destruction efficiency and did not meet regulatory emission requirements.

Replacing the oxidizer would have drastically interrupted the customer’s manufacturing schedule and resulted in capital cost increases that were unacceptable. Anguil’s solution, however, eliminated any production disruptions by performing repairs and design enhancements over several process downtimes. The first step was to immediately replace both the primary and secondary heat exchangers. Anguil designed, manufactured and installed replacement exchangers for this oxidizer. The dismantling, removal and replacement of the exchangers were performed over a three-day weekend when the customer had a scheduled plant shutdown.

The replacement heat exchangers significantly improved the performance of the 13,500 SCFM (21667.5 Nm3/hr) oxidizer. Previously, the oxidizer had to be run for up to six hours to meet the necessary temperature at a fuel cost estimate of $266/per startup. The process air temperature required for the coating machine is now achieved in one hour. The improved efficiency results in operating cost savings of approximately $230 per startup and up to $30,000 annually. The economic impact of the retrofitted heat exchangers went beyond fuel savings; the improved start-up time has reduced plant downtime and increased worker production. The new heat exchangers have also improved the destruction efficiency of the oxidation system and put the company in compliance.

Anguil’s analysis detailed other cost saving suggestions for the company, including:

- Ductwork adjustments for more efficient oxidizer operation

- Heat exchanger maintenance suggestions for all four oxidizers

- Review of safety controls and upgrade recommendations

- Variable Frequency Drive for the fan on the largest oxidizer to accommodate airflow changes more efficiently

- Burner maintenance suggestions

Anguil also performed airflow analysis of all processes. This information will help the company plan for future growth with additional coating lines.

The retrofitted system is currently exceeding the regulatory requirements and providing an efficient heat source for the coating lines. The Anguil service team’s expert troubleshooting and quality turnkey solution capabilities have led to another satisfied customer.

A Competitive Advantage

Comments Off on A Competitive Advantage

At Anguil, our customers know they can trust our team to develop and deliver quality solutions to their unique environmental challenges. In one case, a large semiconductor chip fabricator wanted to reduce their environmental impact, maintain their productivity, save on operational costs, and conserve valuable floor space. We are experts in environmental efficiency through custom design and manufacturing of air pollution, water treatment, and energy recovery systems.

Project Highlights:

- Client needed an abatement system with over 100,000 SCFM (160,500 Nm3/hr) volume processing capacity and over 98% VOC removal efficiency

- Anguil compiled a system of a rotor concentrator wheel, custom-designed thermal oxidizer with a destruction efficiency rate (DRE) of >99.5%, and a specialized heat exchanger

- Each system was able to meet and exceed the processing capacity and destruction efficiency requested, with the processing capacity double that of the two previous systems combined

The Challenge

As a large semiconductor chip fabricator, this customer realized the environmental effects of their operation. The fabrication of semiconductor chips generates significant amounts of wastewater and waste gases, both of which require treatment prior to their release into the sewer system or atmosphere, respectively. As fabrication operations have grown, so too has the amount of waste produced and, consequently, the need for abatement technology.

The customer approached our team with a request for a new abatement system for their plants. They came to us to stay ahead of their competition by tackling the challenge of reducing their environmental impact without sacrificing their facilities’ productivity and output. While they were currently employing the use of two systems, each with capacities for less than 50,000 SCFM (80,250 Nm3/hr), they were looking for a more efficient and effective solution. Ultimately, they were seeking a system that doubled their SCFM volume processing capacity with a 98% VOC removal level.

Their exact system requirements were as follows:

- >100,000 SCFM (160,500 Nm3/hr) volume processing capacity in a single system with the same footprint as the two existing pollution control devices

- >98% VOC removal efficiency

- No upstream pressure fluctuations

The Solution

Once fully assembled, all three systems were installed on mezzanine levels of the existing plants. After installation, our technicians completed final commissioning and provided comprehensive operator training. Ultimately, the customer was left with a system that met their needs and a team trained to properly use that equipment.

The Result

At the end of the project, the customer was fully satisfied with the performance of all three systems. Each system was able to meet and exceed the processing capacity and destruction efficiency requested, with the processing capacity double that of the two previous systems combined and the destruction efficiency surpassing that of the one required.

Learn more about Anguil’s pollution control solutions in this industry.

The Challenge

The Challenge