Anguil’s meticulously engineered systems specialize in high-performance, highly effective pollution control solutions that ensure your battery production processes adhere to stringent environmental regulations while your operations remain optimized.

Applications

- Kiln & Furnace Emission Control

- Battery & Electrode Parts Washing

- Material Mining & Active Material Processing

- Cell Coating & Finishing Solvent Abatement

Challenges Solved

Is this you?

- Your lithium-ion battery production facility emits more than 100 tons of VOCs or HAPs per year.

- You want to incorporate cutting-edge pollution control technologies and replace old systems that can’t keep up with upstream changes.

- Your production process has high emission loading with challenging compliance requirements.

- Your process emits high levels of water and solvent-based gases, such as Normal Methyl Pyrrolidone (NMP), that pose a risk to your community and employees.

The Anguil Advantage

Battery production and manufacturing will be one of the key contributors in the world’s energy transition to a sustainable and environmentally friendly future. That said, manufacturers are looking for innovative ways to keep up with demand while maximizing efficiency and decreasing battery size to offer a more compact convenience to consumers.

Pollution from the process technologies and techniques used to produce batteries can be detrimental to our air, water and soil if the proper abatement technologies are not applied. Solvents and other chemicals used in manufacturing and generated during disposal of batteries can emit dangerous levels of air pollutants like Hydrocarbons, Hydrogen Fluoride (HF), Hydrogen Sulfide (H2S), Sulfur Dioxide (SO2), Sulfur oxides (SOx), Nitrogen oxides (NOx), Carbon Monoxide (CO), Silane (SiH4), and other particulate. Water pollutants are also a major concern as producers attempt to recover the lithium, nickel, manganese, and cobalt entwined within the battery.

Fortunately, Anguil Environmental Systems offers effective, proven technologies that have been applied throughout the production chain; from material mining to powder production, anode coating, battery recycling and component manufacturing.

System Solutions for Compliance; from Material Mining to Testing, Manufacturing, and Recycling

We help manufacturers achieve compliance and accomplish sustainability goals by utilizing proven technologies that are customized to match efficiency needs and removal requirements.

For example, Electrodes are an essential part of batteries that connect with battery terminals as energy enters and leaves to power a device, equipment, etc. During electrode production, the drying process will contribute to the majority of emissions produced during lithium-ion battery production and must be controlled. N-Methyl-2-pyrrolidone (NMP) is a dangerous solvent commonly used in this industry including cathode coating. Although NMP is an effective operating material, it must be used with utmost care due to its toxicity. Anguil abatement technologies have routinely been applied on NMP solvents, helping some of the largest battery manufacturers guarantee compliance with NMP-related emission limitations.

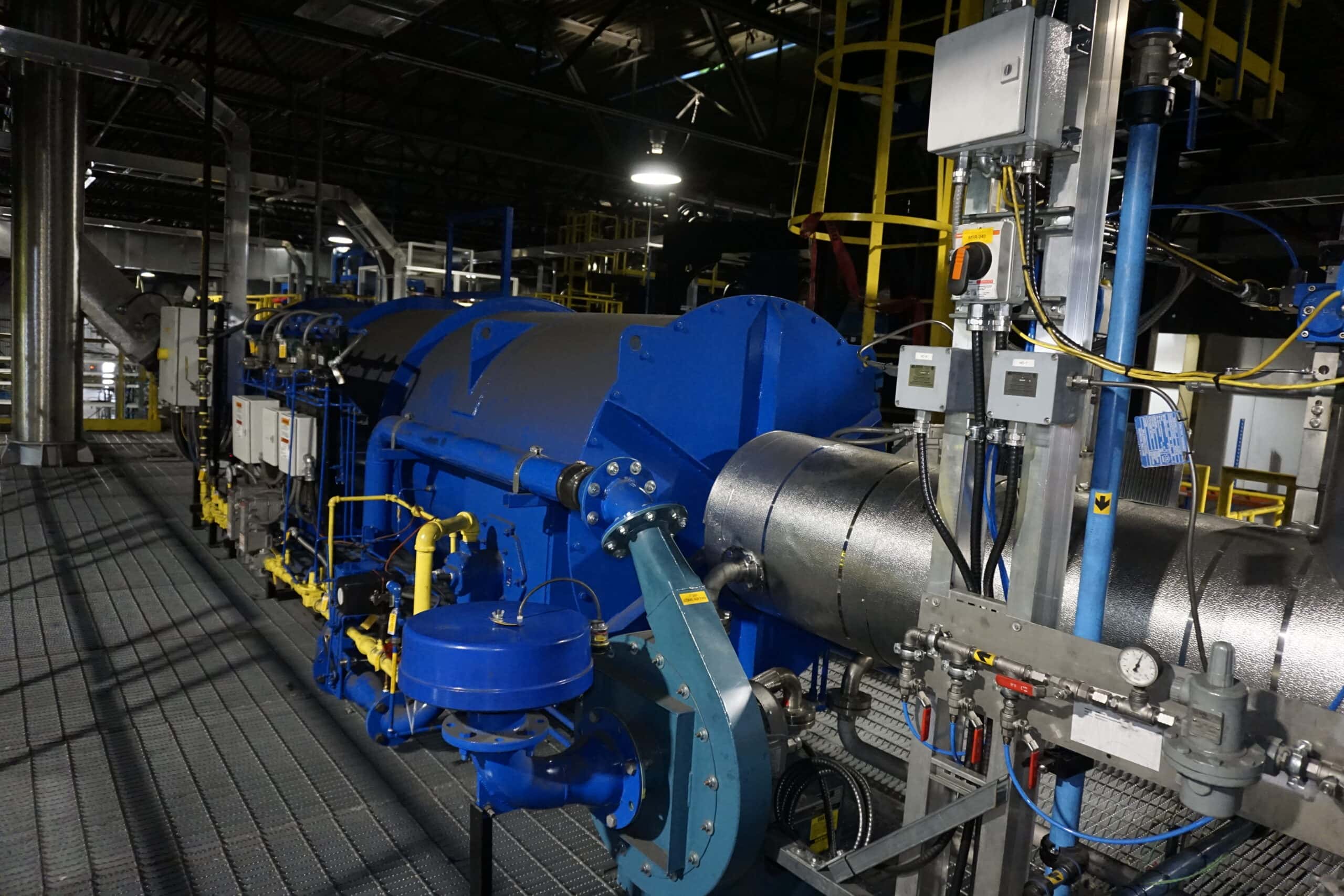

Graphite manufacturing facilities are also benefiting from our state-of-the-art pollution control systems. We developed a multi-stage direct fired thermal oxidizer that is capable of destroying over 99% of the air pollutants without the maintenance concerns that have plagued the application for years. The specialized multi-zone combustion system destroys furnace exhaust without the formation of Nitrogen Oxides (NOx) or tar build up.

Each wastewater treatment application requires a unique treatment process as there is not a universally applied treatment process for battery applications. Contaminants of concern can be metals, total suspended solids, inorganic compounds and a variety of acids. Whenever possible, manufacturers try to recover valuable raw materials and reuse water in the process. A well-designed system will help maintain compliance, reduce operational costs, minimize the risk of operator error, and increase throughput. Because the battery manufacturing processes vary and are ever-changing, it is important to know what contaminants are present in the wastewater before designing a treatment train. Anguil routinely utilizes our in-house lab to test a battery manufacturer’s contaminants before making equipment recommendations.

We specialize in carefully custom-engineered systems and services that lead to a more sustainable and cleaner battery production plant. Our team of experts works closely with battery manufacturers to design and implement custom air pollution control and wastewater treatment systems that effectively capture and destroy emissions, ensuring compliance with strict environmental regulations. Anguil solutions are tailored to your specific process, guaranteeing maximum productivity while minimizing energy consumption and operating costs.

Pollution Reduction Technologies from Anguil Environmental

We strive to deliver complete satisfaction to our clients by providing a full turnkey service, including start-up, installation, and supervision. With an extensive network of service professionals, we can provide the support needed to ensure your system works as intended while Anguil’s diverse product offerings ensures unbiased equipment selection based on efficiency needs, process parameters, and destruction needs. For more information on our solutions, contact us or visit our document library.