EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

Are you ready for the increased compliance challenges?

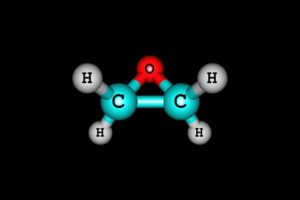

Why is everyone talking about ethylene oxide (EtO)? According to recent scientific studies, EtO is a more dangerous carcinogen than previously thought. Results from the latest National Air Toxics Assessment (NATA) have made EtO an increased focus of concern for the EPA and state regulators. For sterilization companies, this understandably makes you concerned about the safety of your employees and community, as well as your reputation.

In many cases, the traditional abatement technologies such as wet scrubbers and dry sorbents cannot meet the new EtO destruction requirements.

How does your abatement strategy measure up? How do you ensure that your abatement technology is up-to-date and meeting compliance requirements? With so much to lose, why take the risk with an unproven supplier?

A Proven EtO Abatement Equipment Design

Catalytic Oxidizers are one of the most widely accepted control technologies available to control VOC emissions from the EtO sterilization processes.

Anguil systems ensure zero leakage of EtO from the oxidizer and safe operation by integrating the peak shaver, a packed tower counter-flow water scrubber that absorbs ethylene oxide gas into the water by ensuring a high contact area between the gas and the water, preventing unsafe, high concentration conditions.

Sterilizers cannot afford to take the risk on an unproven company. We are proud of our reputation in the industry and our solutions that help ensure safer communities and sterilization operations. Learn more about our sterilization solutions here.

ANGUIL SYSTEM DESIGN FEATURES

- FLEXIBILITY: Base Metal Catalyst offers a large operational temperature window for flow and concentration variations

- COMPLIANCE: Horizontal Catalyst Tray Configuration avoids catalyst bed bypassing per NESHAP requirements

- PERFORMANCE: Leak-and-Dye Tested Shell & Tube Heat Exchanger guarantees 0% leakage of VOC-laden air into clean airstream, reduces operational costs

- SAFETY: Induced Draft Fan functions as a failsafe to prevent leakage into work environment

- DURABILITY: 304L SS Construction With Outer Aluminized Steel Frame increases equipment life, provides low-cost maintenance

- EASE OF USE: PLC With Human Machine Interface and Remote Connectivity System troubleshooting, alerts operator of equipment shutdowns

- ON SCHEDULE: Pre-Assembled, Wired, and Tested Prior to Shipment, can be installed within tight time restrictions due to high production levels

- EVEN, SAFE VOC LOADINGS: Integrated Peak Shaver evens out fluctuations in contaminant levels to a steady state, preventing unsafe, high concentration conditions

Anguil Announces Multi-million Dollar Order for EtO Sterilization Plant

Starting 2021 strong, Anguil announced a multi-million-dollar order for a 15,000 SCFM Catalytic Oxidizer with a Peak Shaver for a new ethylene oxide (EtO) sterilization plant. Anguil’s diversity of experience and wide breadth of technology offerings make us the popular industry choice for the nuanced and varied needs of the pharmaceutical industry where compliance is critical.

Learn more about our solutions for the pharmaceutical industry.

Have an Existing EtO Abator?

If you already have a pollution abatement system on your EtO process, Anguil’s suite of Aftermarket Services can ensure your equipment is optimized for

General Services

- 24/7 Emergency Service

- Routine or Troubleshooting Visit

- Operator Training

- Wastewater Treatment System Maintenance

Retrofits & Upgrades

- Increased Air or Water Flow Capacity

- Improved Destruction Efficiency

- Controls Enhancements

Preventive Maintenance

- Preventive Maintenance Evaluations

- Maintenance Contracts

- Predicative Maintenance Monitoring

Spare Parts

- Individual Spare Parts

- Recommended Spare Parts Packages

- Catalyst & Media

Explore Anguil’s Aftermarket Solutions.

Anguil’s engineers will diligently analyze your challenges and requirements to recommend a comprehensive, turn-key compliance solution. Our suite of quality engineered, air pollution control technologies will efficiently solve your pollution control challenges no matter the complexity. Contact Us to get started with your application.