Getting What You Pay For

Comments Off on Getting What You Pay ForThe Challenge

Background

For any production facility, up-time is paramount. Machines churning and grinding equals profit, and the sound of silence is typically less desirable. For processes that generate dangerous Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs), uptime can be limited by both control of the emissions and safety considerations for your employees.

A tape manufacturer faced such a problem. They required emission control of solvent VOCs from their tape making process. They also wanted to provide a Permanent Total Enclosure (PTE) around their equipment to protect the health and safety of their facility, their employees and maintain a nuisance, odor-free environment.

As experts in the tape industry, they rightly reached out to a small, local engineering firm to design the PTE and size the VOC abatement device. Further, sensitive to their business needs, they approved the lowest cost solution using minimal ductwork and the purchase of a used oxidizer.

However, the decision to entrust their production uptime, worker safety and EPA compliance to an inexperienced consultant

resulted in undersized and malfunctioning equipment, which proved to be disastrous. It is never a best practice to let cost

be the only driver when selecting a technology which may impact production.

A Costly Low-Cost Decision

After having the PTE constructed and the used thermal oxidizer installed, the manufacturer ramped up production and rapidly became aware that the system was not working as sold. The number of air exchanges in the room was inadequate, requiring the employees to labor in gas masks. Moreover, though the used thermal oxidizer suffered from frequent shutdowns, the manufacturer would not support the equipment. More importantly, even when operating, the air pollution control (APC) device could not meet the Destruction Removal Efficiency (DRE) permit requirements, resulting in intermittent production uptime and ultimately a total facility shutdown coupled with the largest non-compliance fine ever levied by the state.

The Solution

A Need For Trusted Expertise

To resolve the situation, the manufacturer brought a more established and experienced consulting firm on board, who immediately realized the capture and abatement system was woefully undersized. The Engineering, Procurement, and Construction (EPC) firm, after putting together new design specifications, reached out to Anguil to assess the abatement device. Anguil visited the site, spoke with the manufacturer concerning their project needs and determined that a Model 50 Regenerative Thermal Oxidizer (RTO) was the ideal solution.

In addition, in the interim prior to the new equipment install, Anguil was asked to try and get the used thermal oxidizer operational. However, it was found the fuel train did not contain the proper valves to control the burner. A plastic bottle cap had been installed in one pressure regulator in an effort to provide enough supplemental fuel. In addition, the wiring for the process damper had never been completed, rendering it inoperable. This last situation is a significant and potentially explosive safety concern.

Despite these challenges, Anguil was able to get the used competitor’s unit operating safely and sufficiently to meet most of their current tape orders. However, the manufacturer had to temporarily relocate production to their overseas facility to meet domestic demand during reconstruction of the PTE, ductwork and installation of the new

Anguil RTO, causing significant business implications including temporary assignment of domestic personnel overseas, increased shipping costs, uncertain lead times as well as all the headaches and hassles coming with coordination of the effort.

The Result

In order to meet the deadline established by the regulatory body to bring the facility back into compliance, Anguil was able to adjust their manufacturing schedule to complete the RTO with sufficient time to perform a full shop test prior to shipping. The unit was shipped, installed and brought up to temperature in a few hours during fresh air commissioning. As soon as process air was sent to the RTO, the Anguil unit met DRE expectations from day one, allowing the facility to ramp up production and provide the desired level of worker safety. Further, because the oxidizer was properly sized (with room for expansion), the manufacturer was able to keep production within normal operating hours and eliminate overtime costs.

If you have a critical production process where every minute of downtime costs you money, don’t use cost as the only decision making criteria. Rather, select a system which meets your production needs, has demonstrated reliability and long-term support from the supplier. If you value uptime, call Anguil today for your VOC and HAP emissions control needs. Sleep well at night knowing that your Anguil air pollution control device will keep you up and running.

Single Source For Success

Comments Off on Single Source For SuccessThe Challenge

A packaging company who had traditionally manufactured steel cans decided to diversify by adding aluminum aerosol cans to their product portfolio. Due to the extensive project scope and a significant capital investment in new equipment including air and water pollution control, the packager stipulated that the successful vendor had to single source the entire project. Since the can making equipment manufacturer who ultimately won the project was not an expert in air and water treatment, they in turn searched for a partner with the ability to single source all pollution control aspects. Anguil, a single source air and water treatment system provider, was selected to be that partner.

The Solution

NAILING DOWN THE REQUIREMENTS

The aluminum can making process requires water to remove oils and post-forming debris as well as chemical surface conditioning of the cans to prep for coating. To accomplish cleaning and conditioning, the cans are passed through a large multi-stage washer, which

- Input water quality (conductivity < 10 micro Siemens)

- Average input flow (30 GPM)

- Required washer input pressure

- The need for a “fast fill” mode to quickly refill the washer after maintenance activities

- The requirement for maximal equipment up time

With customer input, Anguil selected a dual train Reverse Osmosis (RO) system to meet the washer’s influent requirements.

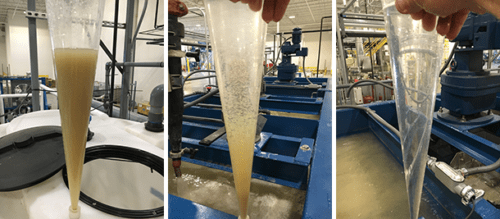

On the wastewater side, where the exact water chemistry was unknown, Anguil again worked with the can manufacturer to determine an expected range of water contaminants to select candidate treatment technologies which could handle the variable chemistry. Expecting a pH of 2-5, high TSS loading, significant amounts of sulfuric and hydrofluoric acids, oils and greases as well as possible surfactants, Anguil proposed a form of enhanced clarification called Ballasted Flocculation (BF). With a BF system, the pH could be adjusted as needed, fluoride and other metals precipitated, and oils broken out of suspension chemically using caustic addition, coagulants and polymers. With the addition of sand to flocculated species, the settling rate increases dramatically, leading to a smaller overall equipment footprint, important since this wastewater treatment system was to be housed inside the production facility. Extra space was left in the system design to allow the addition of water polishing equipment if after start-up, it was deemed necessary.

Because Anguil is an air and water treatment supplier, Anguil was able to evaluate solutions for both treatment needs, ultimately proposing a solution that did not require air pollution control equipment. Again, this fits into Anguil being a technology agnostic solution provider always on the look-out for the customer’s bottom line.

PUTTING IT ALL TOGETHER

After determining the flow and treatment requirements for the Process Water Conditioning System (PWCS) and the Wastewater Treatment System (WWTS), Anguil proceeded to determine the required logistics equipment and controls to operate both systems in automatic mode with the least operator involvement possible.

For example, inlet water buffer and RO permeate storage tanks were selected to supply some onsite storage, ensuring back-up capacity should the city water supply fail and to provide constant, even flow to the varying washer demands. Non-metallic AODD pumps were selected to lift and convey the high solids content and corrosive waste water to the treatment system. An equalization tank and an emergency dump tank were included to buffer flow through the WWTS while providing emergency capacity if the washer needed to be dumped for maintenance reasons, and to collect additional waste water sources from sludge dewatering and secondary containment floor sumps.

In addition to the mechanical components of both the PWCS and WWTS, Anguil’s control engineers worked to integrate both the larger sub-systems (RO, ballasted floc, Rotary Vacuum Drum) into the treatment plant. More importantly, they also worked directly with the canning equipment manufacturer to seamlessly integrate the disparate washer/water treatment systems to minimize production downtime and product loss in the event of failures with the PWCS, washer system or the WWTS.

GETTING THE SYSTEM UP AND RUNNING

After obtaining customer approval of the system design, Anguil ordered the long lead-time items, namely the tanks and large third-party vendor skids. Once these items were on order, Anguil coordinated the purchase and delivery of all the parts (pumps, valves, instrumentation, etc) to be shipped loose for field installation or to be assembled on Anguil pump skids.

Since the canning equipment manufacturer had already obtained the services of installation contractors, Anguil was not engaged for a turn-key installation. However, based on our installation experience with similar systems, Anguil received, labeled each part with its PID drawing tag number, and then “kitted” all the parts into boxes to aid the installation process. For example, all the instruments, valves and piping fittings associated with a given storage tank or sub-assembly were placed in their own box. Kitting parts in this way acted as a quality control step, ensuring the correct parts and amounts were delivered, and greatly assisted the install crew as they knew exactly where and how many parts to install on each tank.

Even though Anguil was not asked to perform installation work, Anguil was hired to provide an install supervisor to interface with contractors, provide guidance where necessary, troubleshoot issues, expedite defective part replacement, communicate the project schedule and handle changing project requirements. One direct benefit of Anguil’s install supervision was the ability to respond rapidly to changing site conditions and requirements. For example, prior to processing cans, the washer system required a “passivation” step consisting of treating the washer interior with caustic and acidic waters. This requirement was not originally intended to be included in Anguil’s scope in any way. However, to assist the customer, Anguil reorganized the installation effort to enable the RO system to be run in manual mode to feed the washer and the wastewater treatment system to be run in manual mode to allow discharge and pH neutralization of the passivation water.

Special site supervision and controls workarounds were required since the equipment had not been fully commissioned and installed at the time passivation was to occur. However, Anguil’s ability to accommodate the project needs saved the customer $100,000s in disposal and transport costs of the passivation water. After can making equipment was brought online, Anguil brought in their commissioning crew to ensure that the control program was operating correctly – especially with communications between the PWCS, WWTS and washer system. This included confirming that chemical protocol was validated and optimized and ensuring that any issues discovered during the initial start-up and shake-down were addressed quickly and efficiently. Ultimately, after training the site personnel on the system operation, troubleshooting of general issues and becoming familiar with system operation, both the PWCS and WWTS were able to support the washer’s input and waste water needs with minimal operator involvement and get the packager back to what they do best—making cans.

The Result

- Anguil was able to walk the customer through a collaborative treatment technology selection process resulting in systems (waste and process) that the customer was comfortable with and had high confidence would meet the desired treatment efficacy.

- Anguil’s approach of sticking to our core competency of engineering and integration led to the selection of technologies and vendors which resulted in a successful water treatment system.

- Anguil’s single source approach enabled streamlined communication when problems arouse. Instead of the customer calling multiple vendors, trying to figure out who owned the problem, they would call Anguil and Anguil led the charge as necessary. One call did it all.

- Anguil’s ability to provide both air and water treatment solutions allowed our engineering experts to explore all possible solutions and design the best fit treatment train — which ultimately removed the need for air pollution control—and lowered the total cost of ownership of the treatment system.

- Even though the customer had already contracted with installation contractors for this project, Anguil’s experience with turn-key installations made it apparent that the logistics of kitting equipment was necessary to ensure project success—all conducted within the original contract price.

- Because of the amount of pre-work done scoping the customer’s needs for both the PWCS and WWTS, no change orders were issued to complete the work—except for those items requested by the customer at a later date.

- Anguil’s customer-focused philosophy enabled us to maintain a flexible schedule to accommodate rapidly changing site demands without significant added costs to the customer.

New Media Makes RTO Natural Gas Usage a Rarity!

Comments Off on New Media Makes RTO Natural Gas Usage a Rarity!The Challenge

Tekra Corporation has always had an eye on their energy conservation. They are a custom coater of plastic films in Wisconsin where state regulations require over 98% of the Volatile Organic Compounds (VOCs) emitted from their process be destroyed in an oxidizer system. While considering their first oxidizer system, Tekra’s Engineers did their homework and invested in an early model Regenerative Thermal Oxidizer (RTO). While at the time RTOs were not the cheapest oxidizer option capital-wise, Tekra knew that long-term, an RTO was their best choice for reliable air pollution control, lower operating costs, and a smaller carbon footprint. “We have always tried to be a green company,” said Zachary Gernetz, Project Engineer for Tekra.

In 2003, it was time for Tekra to replace their aging RTO system, and they turned to Anguil Environmental Systems out of Milwaukee, WI. The equipment of choice was again an RTO, although Anguil’s RTO had significant advantages over the previous model including: 95% TER (Thermal Energy Recovery), lower horsepower, lower operating temperatures, and better options for turndown and idle modes.

“Tekra went so far as to have us install a small odometer-style meter right on the front of the control panel for the Anguil RTO, showing exactly how many BTUs they were saving over their previous unit,” says Greg Blando, Service Manager for Anguil.

The Solution

The Solution

CERAMIC MEDIA RETROFIT

Tekra’s focus on achieving better energy efficiency did not end there. With a new nationwide focus on green business practices and energy costs on the rise, they again challenged Anguil to perform even better in 2009. Anguil studied the temperature charts of the RTO system and took air samples during peak VOC loading production runs and determined that the 95% TER of the system could be pushed closer to 97% without creating any adverse high-temperature conditions in the RTO. Thermal Efficiency of an RTO relates to the ceramic media inside of this type of oxidizer which captures and then utilizes energy from combustion to pre-heat the incoming, untreated airstream.

“A two percent improvement in TER may not sound all that impressive,” says Mike Scholz, Project Engineer for Anguil. “But most RTOs out there today were designed to achieve about 95% TER. The natural gas required by those systems is directly tied to that five percent of energy lost. Getting back two of the ‘lost five percent’ is actually a 40% reduction in energy lost. In practical terms, that two percent improvement in TER can translate into 40% less on your RTO natural gas bill.” In addition, the enhanced performance at Tekra put their oxidizer into a self-sustaining mode more often, meaning the fuel value in the VOC-laden exhaust gases are enough to operate the RTO and no auxiliary fuel is needed, hence fewer greenhouse gases emitted.

PROJECT PAYBACK

Because of advances in RTO ceramic heat recovery media, Anguil is routinely able to provide RTO operators like Tekra with a performance upgrade by either adding to the top of existing media beds or at times, replacing the top several layers of existing beds with new extruded ceramic media blocks. “With this type of project, payback is king,” comments Lee Kottke, a manufacturer’s rep for Anguil closely involved in the Tekra relationship. “That’s why it is exciting that Anguil can achieve this level of success with only partial media change-outs. That keeps the project cost down and payback periods very reasonable.”

There are other possible effects on project payback to consider. Deeper media beds may require the relocation of chamber instrumentation – like thermocouples. Also, higher efficiency media styles can come with increased back pressure and electrical horsepower cost. Often, however, as in the case of Tekra’s RTO, the electrical penalty is minor compared to the natural gas savings.

Gernetz said that with two coaters running a variety of coating weights and line speeds, it is difficult to get an exact dollar savings. However, prior to the media replacement their RTO often required natural gas to maintain temperature when only treating the exhausts from one coating line. Post retrofit, “the RTO rarely requires natural gas even when only one coater is operating and never when both are on,” says Gernetz. Zach added, “Jobs that were never self-sustaining before are now, so I know that the media retrofit is saving us money.” He estimates a two year payback for this retrofit.

The Result

Considering some enhancements to your RTO? Think about this:

- Up until recently, most RTOs were designed with 95% Thermal Energy Recovery (TER%) or less.

- Rule of Thumb for a self-check: If the average RTO outlet temperature is more than 100°F higher than the RTO inlet temperature, your actual TER% is probably less than 95%.

- Even a small increase in TER% can have a dramatic effect on RTO fuel usage. In some cases, a bump in TER% could eliminate RTO fuel use entirely.

- Advances in ceramic media have allowed Anguil to improve TER% in RTOs by only replacing a portion of the existing ceramic media beds, improving payback periods.

- Anguil has performed this retrofit on numerous RTOs, regardless of original manufacturer, and we offer free savings analysis for those interested.

According to Chris Anguil, President of Anguil Environmental Systems, Inc, “When I reflect on the relationship between Anguil and Tekra, it strikes me how RTOs, while such a huge leap forward in energy efficiency over previous oxidizer styles, are continuing to evolve. Advances in media and controls mean there is still room for efficiency improvements on any RTO system out there, regardless of age. Anyone owning an RTO should follow Tekra’s lead and continue to ask if they can do even better energy efficiency-wise. We applaud Tekra’s commitment to environmental compliance and energy efficiency and thank them for challenging us with this opportunity.”

Flexographic Printer: Efficient Emissions

Comments Off on Flexographic Printer: Efficient Emissions The Challenge

The Challenge

Control of air emissions has become an important issue that flexible packaging converters must consider when changing or upgrading equipment. A producer of printed shrink films, bags and pouches for a diverse range of applications addressed its emissions in 1991 and 1996 by investing in two Anguil catalytic oxidizers to control the EPA-regulated air emissions generated in their various processes.

But when the company decided to purchase a new 10-color gearless press to increase capacity and capability years later, management knew they also needed to determine if an alternate technology would reduce their operational costs compared to their two catalytic oxidizers.

The Solution

Having supplied the original catalytic oxidizers, the customer contacted Anguil Environmental to analyze the most cost-effective and compliant way to replace the two aged systems. After an analysis, Anguil recommended replacement of the existing equipment with a single 25,000 Regenerative Thermal Oxidizer (RTO).

The Result

RTOs Replace Catalytic Oxidizers

Though the catalytic units were a logical choice at the time of purchase, technological advances in the ensuing years had caused the RTO to become a much more viable abatement strategy.

Now 15-20 years following the original catalytic oxidizer installations, the customer and Anguil’s objectives were to:

- Achieve destruction of 98 percent of the Volatile Organic Compounds (VOCs) in the press exhaust

- Fit the system into limited space

- Complete the tear-out and subsequent installation in just six days

The operation of the RTO is considerably different from the existing catalytic units. The oxidizer consists of two reinforced, insulated chambers filled with high temperature structured ceramic energy recovery media. The oxidizer utilizes a burner to maintain the oxidation temperature. Located beside the energy recovery chambers are diverter valves and air duct plenum passages, which allow the press exhaust to be diverted into and out of the oxidizer in either a clockwise or counterclockwise mode. The directional mode is controlled by a PLC, which changes the direction of airflow at regular intervals to optimize system efficiency.

The RTO in Action

The RTO in Action

In operation, solvent laden air (SLA) enters the oxidizer via an energy recovery chamber where the high temperature ceramic heat transfer media preheats the SLA prior to introduction into the oxidation chamber. As the SLA passes up through the bed, its temperature rapidly increases. After the chemical oxidation purification reaction occurs, the hot, clean, outgoing gas heats the exit energy recovery bed. In order to maintain optimum heat recovery efficiency, the SLA flow direction is switched at regular intervals by the automatic diverter valves on demand from the PLC control system. This periodic flow direction shift provided a high thermal efficiency to minimize customer operational cost.

With sufficient concentration of hydrocarbons in the process air stream, the heat energy content of the VOCs will result in self-sustained operation with no auxiliary fuel usage.

Features that are specific to the RTO include:

- High volumetric turn-down capability, enabling the control of multiple presses and the reduction of operating cost.

- Thermal energy recovery of 95 percent or higher, allowing self-sustaining operation with no auxiliary fuel usage at levels as low VOC exhaust concentrations..

- Customized thermal energy recovery media, providing low-pressure drop and low electrical cost.

Anguil’s vast experience, gained after supplying more than 2,000 successful systems around the world, provided the confidence necessary for this customer to choose Anguil as their continued VOC control supplier for three decades and counting. Anguil was able to modify its standard RTO design to fit into the space provided and to execute tear-out and new installation within a short timeline. The result was a system that exceeded the 98 percent destruction efficiency objective while lowering operating cost by more than 60 percent.

Converter Finds Affordable Compliance Solution

Comments Off on Converter Finds Affordable Compliance Solution The Challenge

The Challenge

It’s not just about increasing production for Fredman Bag’s president, Tim Fredman Jr., it’s also about being an environmentally conscious neighbor. A converter’s decision to expand their capacity is often made more complicated by a corresponding need to invest in air pollution control equipment. Recent expansions had Fredman Bag making major investments in their air pollution control equipment not only to meet EPA (Environment Protection Agency) regulations but also keep their reputation as a good neighbor.

The Solution

Fredman Bag, a Milwaukee-based flexible packaging converter purchased a new, eight-color, gearless CI-flexo press from Uteco Converting to adapt to their customer’s growing needs, enhancing their product offering and delivery capabilities. The gearless-press runs at faster speeds with a higher resolution, printing a superior-quality product and increasing production for Fredman Bag by nearly 40%.

The VOCs (Volatile Organic Compounds) and HAPs (Hazardous Air Pollutants) emitted by a printing press are not only harmful to the environment but also people who breathe them. Fredman Bag had been using an Anguil 6,000 SCFM (9,630 Nm3/hr) catalytic oxidizer as an effective means of air pollution control before their expansion but the increase in emissions and flow from the new press was beyond the capacity of the existing 10-year old oxidizer. After serious consideration, Fredman again turned to Anguil Environmental Systems, also a Milwaukee based firm, to address their pollution control needs.

The Result

The Result

Anguil’s application-specific engineering, stressing air volume reduction, energy-efficiency and improved emissions capture provides an affordable and flexible solution. Taking into consideration future growth, a 12,000 SCFM (19,260 Nm3/hr) Regenerative Thermal Oxidizer (RTO) was selected to ensure regulatory compliance. The Anguil RTO technology provides significant operating cost savings.

The Anguil two-chamber RTO heats exhaust air from the printing presses as it passes through beds of ceramic media located in an energy recovery chamber. The process air moves from the recovery chamber toward the combustion chamber, where the VOCs are oxidized, releasing energy into the second energy recovery chamber. A diverter valve switches the airflow direction so both energy recovery beds alternately store and release energy to minimize operating costs by reducing any auxiliary fuel requirement. This system is designed for heat recovery of over 95% and is self-sustaining, requiring little if any auxiliary fuel even with low VOC loadings. This energy-efficient recovery means the Anguil RTO offers lower operating costs over other emission treatment methods. As a result of Fredman’s decision to use the energy-efficient Anguil oxidizer, the company was eligible for Wisconsin Energy’s, Focus on Energy program. The incentives they received allowed them to go ahead with the project sooner than they had initially hoped.

Lost production was another concern for Tim Fredman, Jr. Air pollution control equipment doesn’t increase a manufacturer’s bottom dollar like other capital equipment does but it can often cost them significantly in downtime. Anguil took careful measures to assure that there were no disruptions in Fredman’s process. By utilizing existing ductwork, preparing accordingly and coordinating with the customer, Anguil was able to install the complete system in under three days. The oxidizer was delivered to Fredman Bag on a Thursday during a scheduled maintenance shutdown, installation was complete by Saturday and start-up was done that same day, saving the converter any lost production.

The Anguil system can be monitored and controlled 24/7 from remote locations for ease of troubleshooting and adjustments, eliminating unnecessary service calls. It has a high volumetric turndown capacity to minimize operating costs during process idle, downtime or on weekends. The Anguil oxidizer has been operating, maintenance free at 99% destruction rate efficiency since start-up. A trouble free air pollution control system allows Tim Fredman Jr. to concentrate on production and sales, knowing his company is in compliance.

Coater Replaces Old Oxidizers with Energy Efficient Systems

Comments Off on Coater Replaces Old Oxidizers with Energy Efficient Systems The Challenge

The Challenge

Emission control and the operating costs associated with meeting environmental regulations were nothing new for the Coated Products Division of Brady Corp. The company has been manufacturing coated films for nearly 60 years, demonstrating over that time a commitment to pollution prevention and emission reduction programs. But these considerations were magnified when the Milwaukee coating facility chose to implement a new, energy-efficient emission control system. The division maintains 200 different coating formulas on three main continuously operating process lines. Two of the company’s three coaters are operated as so-called “white rooms” to allow the manufacturing of exceptionally clean products. Applying adhesives, topcoats, cast films and other coatings onto a range of substrates requires solvent-based coatings with mixtures of chemicals. Some of the many solvents used in the process are: toluene, MEK, MIBK, heptane, hexane, ethyl acetate, IPA, nitroethane, nMP, cyclohexanone, and 1,3-dioxolane. The dynamic process stream poses many challenges to the company, particularly in that it eliminates the option of solvent recovery.

The Solution

The capital cost of emission control equipment can be negligible compared to the operating costs if careful consideration is not given to proper equipment selection. With natural gas prices continuing to rise, the company has focused on getting the most efficiency from its incineration equipment. Since the early 1990s, the facility has spent millions of dollars on air pollution control equipment to meet a variety of EPA regulations imposed on coating companies. Including thermal recuperative and regenerative thermal oxidizers (RTOs), as well as concentrator systems, the company has purchased a total of 12 units with a 13th on order for the Milwaukee location alone. The oxidizers have been used to treat everything from coating emissions to low-point floor sweeps located throughout the facility. As natural gas prices started rising in the late 1990s, and with associated costs for emission control equipment steadily increasing, the company looked for ways to reduce their yearly operating and maintenance costs.

The operating and maintenance costs were overwhelming. When one of the old electric RTOs would fail, it generally took over a week to replace the cold face support grid and electric heating elements, and then bring the unit back up to temperature. It occurred so frequently that the maintenance department constructed a special tent so the repairs could be done in the rain or snow. The thermal recuperative oxidizers on site had so many problems with internal heat exchanger failure that a roller system was installed just to move the large duct transition, allowing access to weld the tube sheet without bringing in a crane.

The Result

The Result

The decision was made to begin replacing the oldest and least efficient oxidizers; the type of systems would be determined by the maintenance team. The first phase of what plant personnel started referring to as its “efficient emission control plan” would replace one of the thermal recuperative oxidizers with a 35,000 SCFM (56,175 Nm3/hr) RTO from Anguil Environmental Systems Inc.

The new system tested out at a destruction efficiency rate of 99.2 percent, and was equipped with a hot-gas bypass that allowed it to process VOCs at rates up to 850 lbs/hour. This high-capacity VOC processing allowed some of the other less efficient oxidizers to shift their load over to the new RTO through a unique common manifold collection system. With the concentration of hydrocarbons in the process air stream, the heat energy content of the VOCs was self-sustained and the oxidation process required no additional fuel for destruction.

RTO technology utilizes ceramic media in two or more beds as a high-efficiency heat exchanger. Process gas with VOC contaminants enters the RTO through an inlet manifold. A flow diverter valve diverts the gas into an energy recovery chamber, which preheats the process stream. The process gas and contaminants are progressively heated by the ceramic bed as they move toward the combustion chamber.

The VOCs are then oxidized, releasing energy that is transferred to the second ceramic bed, thereby reducing any auxiliary fuel requirement. Heat is transferred from the gas to the ceramic bed so that the outlet gas temperature is only slightly higher than the inlet temperature. A flow diverter valve switches, alternating the ceramic beds so each is in inlet and outlet modes over time. If the process gas contains sufficient VOCs, the energy released from their combustion promotes self-sustained operations. For example, at 95-percent thermal energy recovery, the outlet temperature may be only 77°F higher than the inlet process gas temperature.

The maintenance team investigated several types of RTO systems, including a new rotary valve system. The rotary valves seemed to be a viable option, but they were a close-tolerance proprietary item that could only come from the specific vendor. The rotary valve location underneath the RTO also presented major maintenance concerns. The company went with Anguil’s poppet valve design, believing the maintenance levels were more satisfactory.

The company also was pleased that the RTO manufacturer was willing to share its complete computer operating program, something other vendors were not willing to do. Some of the other items on the system included:

- A stairway for access to platforms rather than the usual vertical ladders – a feature especially appreciated in Wisconsin winters

- Replaceable valve seats on the poppet valves and large access doors.

- Heavier gauge access doors with fewer bolts to be removed.

- Block-off plates after the system fan as required for confined space entry.

The second stage of the plan would prove to be a little more challenging, but even more effective in reducing the company’s operating costs. The EPA’s requirement of a permanent total enclosure, or PTE, required coaters to create a negative pressure in all areas of the facility that process any volume of solvents. Due to the layout of the coaters, this became a large volume of exhaust air with very low VOC levels.

Two of the old electric RTOs were treating this high-volume, low-concentration stream from pump rooms, wash-up areas, compounding areas and floor sweeps located throughout the facility. Large volumes of natural gas were consumed to burn a very small amount of pollutants. In addition, the unit could not be turned off during plant shutdowns because of time-consuming reheat procedure, which could take up to four days.

After evaluating the solvent vapors and various concentrations, an Anguil Model 350 (35,000 SCFM, 56,175 Nm3/hr) rotor concentrator and Model 50 (5,000 SCFM, 8,025 Nm3/hr) RTO were selected to handle this portion of the process. By absorbing and concentrating the VOCs they were able to achieve a 10-to-one concentration ratio, requiring an oxidizer only a tenth the size to handle the concentrated process stream. The energy contained in the concentrated stream entering the RTO proved sufficient to allow self-sustaining operation, requiring little to no auxiliary fuel.

The third but not final stage of the company’s plan is still in motion. They have placed an order for another 35,000 SCFM (56,175 Nm3/hr) RTO to replace the last thermal recuperative system on site. When this system has been installed, heat from the RTO will be used to preheat the facility’s ovens, further reducing energy consumption. The system will have enough capacity to eliminate the final thermal recuperative unit and another aging electric RTO.

In addition to replacing old oxidation technologies at the facility, careful consideration has been given to all the oxidizers as a single system. The company has implemented a dual collection and distribution manifold that allows operators to divert process streams from one oxidizer to another for maintenance or equipment shutdowns.

The impact of these efforts has exceeded expectations for reliability and efficiency. Gas usage on the company’s three coating lines have continued to drop at a steady rate. At a time when gas prices continue to trend high, coupled with increases in production, the reduction in energy consumption drops straight to the bottom line.

The company is continuing to investigate energy reduction strategies, and is currently investigating the option of placing secondary heat exchangers on all of its oxidizers. The process would return waste heat to preheat the air streams on all of its other coating lines.

The Solution

The Solution The Challenge

The Challenge The RTO in Action

The RTO in Action The Challenge

The Challenge The Result

The Result The Challenge

The Challenge The Result

The Result