Oxidizer System Optimization

Comments Off on Oxidizer System Optimization The Challenge

The Challenge

OXIDIZER SERVICE SERIES: PART 4

As promised, this is the fourth installment of Anguil’s Oxidizer Service Series. If you have read through the first three parts, this can be seen as a capstone of those efforts. Having a strong oxidizer service plan, backed up with recommended spare parts and all of the proper documentation will not only improve your system performance but also allow you to focus on optimizing your oxidizer efficiency. Setting all of these aspects in place within your overall maintenance plan will help you become proactive in ensuring your system’s reliability. However, this does not take into account how much you are spending on a daily basis to operate. So, how much is your oxidizer costing you to operate? Do you know how much it should be costing you to run if it’s running efficiently? A fully optimized oxidizer will help you save money on operating costs, reduce your greenhouse gas footprint, and contribute to your bottom line in very measurable ways.

The Solution

Oxidizer system optimization can fall into two categories. The first is “reactive,” meaning you identify and respond to the small inefficiencies that may occur over the life of an oxidizer system. The second would be “proactive.” It is our goal that all of the tools we are providing you within this compilation allow you to act proactively, with the goal of you integrating these tools into your overall maintenance plan.

Things to Consider:

- Over the course of a year, unnecessarily treating an additional 1,000 SCFM (1,605 Nm3/hr) of process exhaust in an oxidizer system can cost upwards of $10,000 with an RTO and over $30,000 for a thermal recuperative system.

- Making a modest improvement in the Thermal Energy Recovery (TER) of an RTO system – even as little as 1% – can cut natural gas bills by 20% or more.

- Most emission abatement systems are designed and installed based on a theoretical projection of future production levels often with a safety factor included. If an oxidizer remains at a facility for 15 to 20 years as many do, it is very unlikely that an existing system is optimized for current production conditions, emission characteristics, and process demands.

It is also important to know that most emission abatement systems are designed and installed based on a theoretical projection of future production levels. If an oxidizer remains at a facility for 15-20 years, it is very unlikely that an existing system is optimized for current production conditions, emission characteristics, and process demands.

Plant managers owe it to themselves to periodically review the operating costs associated with their oxidizer system. This periodic review will allow for informed decisions about both reactive and proactive efforts, translating directly into lower operating costs. If PMEs or testing of the oxidizer is regularly required and included in your maintenance plan, this is an excellent time to schedule an operating cost review. Operating costs can be reviewed during monthly or even weekly walk-by inspections and checklists. These inspections are typically performed by your own personnel. However, Anguil can provide you with a checklist for Monthly Maintenance Day inspections of the system components needing inspection, independent verification, and/or calibration on a monthly basis. The more your maintenance team knows about your system and their capability to perform checks like this on their own, the more money you will save, and the more efficient your system will run.

Optimization Strategies

Optimization Strategies

What follows are some general strategies for oxidizer optimization, applicable to a wide-range of system types. With limited historical information, an oxidizer company like Anguil can quickly determine which of the following strategies could be a good fit for you.

KNOW HOW MUCH YOUR OXIDIZER IS SUPPOSED TO BE COSTING YOU TO OPERATE

Make sure you can answer the following questions:

- What is the expected annual operating cost of our oxidizer?

- How close is our actual operating cost to that expected value?

With relatively minimal inputs, oxidizer vendors can run a performance model and give you the expected operating cost range for your system.

PAY ATTENTION TO THE PERCENTAGES

After five years of operation, an RTO originally designed for 95% Thermal Energy Recover (TER) could easily slip to 93% TER. This might not sound like a big deal, but that decrease in TER actually equates to a 40% increase in natural gas consumption. Percentage points do accrue over the course of a year, so get to know the critical parameters to watch as your system ages.

KNOW YOUR EMISSION LOADING – ESPECIALLY THE AMPLITUDE AND DURATION OF PEAKS

Especially the amplitude and duration of peaks. The size of an oxidizer is almost always determined by the peak emission levels coming from an application, but it is the average emission loading that dictates operating costs. Estimates for future “worst case scenarios” are made in the design phase to ensure a system is not undersized. After a couple years of operation, examine your actual day-to-day production loading to make sure you are not operating an oxidizer designed to handle a theoretical peak loading which you would in fact never reach.

KNOW WHAT OXIDIZER SYSTEM WOULD BE SPECIFIED FOR YOUR PROCESS TODAY

Vapor combustion technologies have evolved over the years. Knowing what is specified for your application in today’s energy conscious market can illuminate cost effective upgrades to existing equipment. Alternatively, an entirely different oxidation technology may be specified for your application today, so knowing what is currently available can save you from sinking too much money into an outdated oxidizer system.

IMPROVE PRIMARY HEAT RECOVERY

Oxidizers are typically designed with internal heat recovery. Usually, hot purified gases leaving the combustion chamber are used to pre-heat the incoming solvent laden air stream, which is the primary heat recovery of an oxidizer system. Projects improving the primary heat recovery of an oxidizer system offer the quickest payback because they provide additional heat recovery at all times the oxidizer is in service. For example, a coating company increased the primary heat recovery in their RTO and the system is now self-sustaining, meaning no supplemental fuel is required during most operating conditions. This coating company increased the primary heat recovery in their RTO and the system is now self-sustaining.

CONSIDER SECONDARY HEAT RECOVERY

If improving primary heat recovery is not cost effective or oxidizer operating conditions do not allow it, secondary heat recovery may be the best option for conserving the heat input to an oxidizer system. Heat exchangers can be added to the exhaust stack of an existing oxidizer to capture excess stack heat in air, water, or even steam. There are a wide variety of low back-pressure designs that can be added to an oxidizer’s stack without requiring a replacement of the oxidizer system fan. See our Oxidizer Energy Recovery Options article for an in-depth look at this optimization strategy.

FOCUS ON COMBUSTION AIR

FOCUS ON COMBUSTION AIR

Combustion air, in both your oxidizer system and process burners, is often overlooked as a potential area for operating cost savings. Making sure burners are tuned properly and only firing when necessary can make a big difference. With RTOs, there is an additional money saving opportunity to install flameless supplemental fuel injection (SFI) systems where combustion air is not needed at all. Also, retrofit options that utilize a heat exchanger to supply combustion air from the chamber or stack.

INVESTIGATE AN EMISSION CONCENTRATOR

Burning air is expensive. In fact, fuel usage for most thermal and catalytic oxidizers will decrease as emission levels increase. If a significant portion of the process air being treated is near ambient temperature with low levels of contaminants, an emission concentrator may be an optimization option for your facility. Often utilized on paint booths and floor sweeps, this technology is capable of absorbing emissions and converting them into a smaller, more fuel rich air stream that reduces the heat input required by a combustion device. Concentrators can increase the capacity of an oxidizer by a factor of eight to 25 when added upstream of an existing system.

KNOW WHAT GRANT MONEY IS AVAILABLE TO YOU

Energy reduction upgrades to existing equipment will have an associated capital cost. These expenses can often be supplemented with grant money from utility companies if there is a significant reduction in fuel usage and/or electrical consumption. Know what grant money is available to you, whom to contact, when, and how to apply. Anguil routinely partners with our customers to secure grant money on applicable projects. We have found the Database for State Incentives for Renewables & Efficiency (DSIRE) to be a great resource.

PROPERLY MAINTAIN EXISTING SYSTEMS

No matter how well an abatement system is designed and manufactured, it cannot continue to operate at high efficiency levels without maintenance. Small inefficiencies in system operation can lead to large operating expenditures over the course of a year. While a formal maintenance plan with checks and balances is ideal, it is often not feasible. However, as noted in part two of the Oxidizer Service Series on Crafting a Maintenance Plan, there are basic service guidelines which can help improve uptime, keep you in compliance and reduce operating costs. With today’s energy prices, a regular service schedule can pay for itself many times over.

The Result

Anguil has written extensively on oxidizer operating cost reduction strategies. For more in-depth information that is not included in these optimization suggestions, view the full version of Anguil’s Operating Cost Reduction Strategies.

This is the fourth and final installment in Anguil’s Oxidizer Service Series. We encourage you to also view Part 1: Better Maintenance Starts With Better Documentation, Part 2: Crafting Your Oxidizer Maintenance Plan and Part 3: Stocking Spare Parts for Your Oxidizer System.

Optimizing Performance with Media and Controls

Comments Off on Optimizing Performance with Media and Controls The Challenge

The Challenge

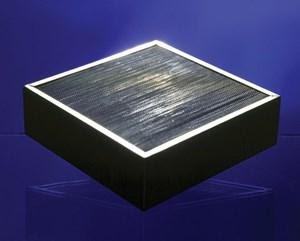

Anguil Environmental Systems performed a series of upgrades on a 25-year-old three-chamber Regenerative Thermal Oxidizer (RTO) originally manufactured by Smith Engineering.

The Solution

The goal was to extend the life of the unit and improve its operating performance for this wall covering manufacturer. The oxidizer’s media was replaced with an extruded monolith block media to increase the thermal energy recovery (TER) of the unit while maintaining its VOC destruction efficiency. The new media provides the owner with an operating savings of over $250,000 per year.

Along with new media, Anguil improved the airflow distribution of the system by installing new stainless-steel cold face perforated sheets and media supports. Proper distribution of the incoming air increases the system’s thermal efficiency and ensures proper destruction of VOCs. The insulation was repaired or replaced where needed to eliminate exterior hot spots.

The Result

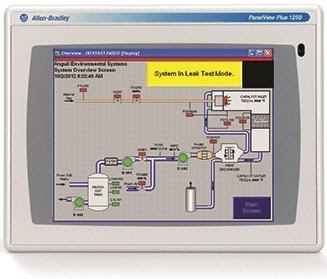

The new media significantly reduced the oxidizer operating costs. The new control panel provided the customer with new up to date drawings and the latest panel components to be able to monitor and control the RTO more easily.

Operating Cost Reduction Strategies

Comments Off on Operating Cost Reduction Strategies The Challenge

The Challenge

More and more, companies operating air pollution control equipment today realize that the initial capital cost of an oxidizer system can be rapidly eclipsed by continued operating expenses if careful attention is not periodically given to the system.

The Solution

Below are ten tips to ensure your oxidizer is operating at peak performance. The first five tips focus on parameters end-users should know about their oxidizer systems, while the last five address energy reduction projects to be considered.

The Result

1. Know how much your oxidizer is supposed to be costing you to operate.

It is surprising how many facilities cannot answer the following two questions.

- How much is our oxidizer operation expected to cost?

- How close is our oxidizer operating to that expected value?

The “out of site, out of mind” approach is entirely too prevalent when it comes to air pollution control equipment. While that speaks highly for the reliability of systems installed today, it also hints at a blind spot around the day-to-day operating cost of oxidizer systems. With relatively minimal inputs, oxidizer vendors can run a performance model for you and give you the expected operating cost range for your oxidizer system.

2. Pay attention to the percentages.

After five years of operation, a Regenerative Thermal Oxidizer (RTO) originally designed for 95% TER (Thermal Energy Recovery) may have slipped to 93% TER. This might not sound like a big deal, and this may go unnoticed by even the most attentive maintenance department. However, an average sized RTO (25,000 SCFM, 40,125 Nm3/hr) operating for a full year at 93% TER versus 95% TER could cost upwards of an additional $65,000.00 a year! Percentage points do count over the course of a year. Get to know the critical parameters to watch as your system ages.

3. Know your VOC loads – especially the amplitude and duration of peaks.

Often it is peak VOC (Volatile Organic Compound) loads that determine your oxidizer design, but average VOC loads that determine your oxidizer operating cost. When an oxidizer is specified, designed, and installed, oftentimes it is the anticipated VOC loading peaks that dictate the amount of heat recovery incorporated. Typically, estimates for a future “worst case scenario” are made to ensure a conservative approach is taken. After a couple years of operation, it may be time to examine whether the design was too conservative and the peak solvent usage is much lower than originally estimated. Operating an oxidizer designed to handle a theoretical peak loading may be costing you much more than necessary for your actual day-to-day production loading.

4. Know what oxidizer system would be specified for your process today.

Finding out exactly what would be specified to treat your process exhaust today is a valuable exercise, especially if your existing equipment is in need of significant repairs or upgrades. Knowing what would be specified in today’s energy conscious market can serve to illuminate cost effective upgrades to your existing equipment.

For instance, five to 10 years ago, an RTO with 90% heat recovery may have been specified to treat your process exhaust. Today, oxidizer vendors may prescribe an RTO with 95% or 96% heat recovery and a hot gas bypass damper to deal with high VOC loading periods. If your existing oxidizer system is due for repairs, a service provider such as Anguil can also determine whether it would be cost effective to upgrade to today’s standards at the same time.

Alternatively, it may be a completely different oxidation technology specified today. With today’s control schemes, RTOs have expanded their applicability greatly over past years, while also dropping significantly in initial capital cost. Knowing exactly what would be specified today can save you from sinking too much money into an outdated oxidizer system.

5. Know what grant money is available to you.

Energy reduction upgrades to existing equipment will have an associated initial capital cost. This can be significantly reduced with grant money from local utility companies. Across the country, money has been earmarked for the specific purpose of funding energy reduction projects. Know what grant money is available to you, whom to contact, and when and how to apply. The main intent of these programs is to take upgrade projects that you (or your management) may be on the fence about and contribute the funds necessary to make them very attractive.

6. Concentrate high volume low VOC airstreams prior to oxidizer.

If a significant portion of the air entering your oxidizer is at or near ambient temperature with low levels of VOC loading, a VOC concentrator may be applicable for reducing the heat input required by your oxidizer system.

As a result of recent regulations, many facilities around the country have been forced to improve localized VOC capture as well as prove high destruction efficiency in their oxidizer system. In many cases, this has led to the installation of additional capture hoods or enclosures and increased the amount of air to be treated by a particular oxidizer system. A concentrator can take exhaust air at or near ambient temperatures and concentrate it so that what is actually sent over to the oxidizer system is reduced by a factor of eight to 15 times. This greatly reduced airflow is typically fuel-rich with VOCs and much less of an operating cost burden on the oxidizer system.

7. Focus on combustion air.

Combustion air, both in your oxidizer system or in your process burners, is often overlooked as a potential area for operating cost savings. Next to the main oxidizer system fans, the smaller combustion fan supplying high-pressure air across the oxidizer burner can seem insignificant. However, these smaller fans, more often than not, are supplying fresh air at outdoor temperatures directly into the oxidation chamber where it must be heated to full oxidation chamber temperature. At a temperature difference usually over 1400 F, it does not take much airflow over the course of a year to add up to significant operating cost dollars.

Making sure burners are tuned properly and not firing on excess combustion air can make a big difference. With RTOs, there is the additional opportunity to install a flameless fuel injection system where combustion air is not needed at all. Finally, even with a perfectly tuned burner, combustion air can be preheated using a heat exchanger or a blend with stack air.

Oxidizers are typically designed with some form of internal heat recovery. Usually the hot purified gases leaving the combustion chamber are used to pre-heat the incoming pollutant-laden airstream. This is referred to as the Primary Heat Recovery of an oxidizer system. Projects that improve the primary heat recovery of an oxidizer system often offer the quickest payback because they provide additional heat recovery at all times the oxidizer is in service. For recuperative thermal and catalytic units, this typically consists of adding additional passes to the internal air-to-air heat exchanger. For RTOs and RCOs this would be handled with increasing or changing the type of ceramic heat recovery media or changing the control scheme that dictates how often beds are switched from inlet to outlet.

9. Consider secondary heat recovery.

If improving primary heat recovery is not cost effective, or oxidizer operating conditions do not allow it, secondary heat recovery may be the best option for utilizing the energy output of the combustion process within an oxidizer system. Heat exchangers can be added to the exhaust stack of an existing oxidizer to capture excess stack heat in air, water, or even steam. There is a wide variety of low back-pressure designs that can be added to an oxidizer’s stack without requiring a replacement of the oxidizer system fan. Direct-fired and thermal recuperative designs often offer the most potential payback for add-on heat recovery systems.

Payback for these projects is greatly improved if the captured heat can be used back in the exhaust generating process itself, because again, it is assumed that the process is operating at all times the oxidizer is operating. For example, fresh air is passed through a secondary heat exchanger in an oxidizer exhaust stack and supplied back as base loading for the oven zones the oxidizer is treating. Every time the oxidizer is on the oven zones require heat, so this heat recovery project pays back all year long. If the same fresh air was supplied back to the plant as tempered makeup air, this may only provide payback during the heating season.

Following this logic, in the past comfort heat applications may have been ignored. But considering today’s unstable and rising fuel costs, coupled with the energy recovery grants available to facilities, these projects deserve attention.

10. Properly maintain existing systems.

Finally, no matter how well an overall system is designed, it cannot continue to operate at a high efficiency level without proper maintenance. A handful of small inefficiencies in system operation can lead to large operating cost bills over the course of a year. At today’s energy prices, regular calibration of feedback instruments and control loops can pay for itself many times over.

All too often, production facilities take the “No News is Good News” approach to their air pollution control equipment when they really should be chasing the benefits of “Company Stays Green and Saves Green” headlines instead.

New Media Makes RTO Natural Gas Usage a Rarity!

Comments Off on New Media Makes RTO Natural Gas Usage a Rarity!The Challenge

Tekra Corporation has always had an eye on their energy conservation. They are a custom coater of plastic films in Wisconsin where state regulations require over 98% of the Volatile Organic Compounds (VOCs) emitted from their process be destroyed in an oxidizer system. While considering their first oxidizer system, Tekra’s Engineers did their homework and invested in an early model Regenerative Thermal Oxidizer (RTO). While at the time RTOs were not the cheapest oxidizer option capital-wise, Tekra knew that long-term, an RTO was their best choice for reliable air pollution control, lower operating costs, and a smaller carbon footprint. “We have always tried to be a green company,” said Zachary Gernetz, Project Engineer for Tekra.

In 2003, it was time for Tekra to replace their aging RTO system, and they turned to Anguil Environmental Systems out of Milwaukee, WI. The equipment of choice was again an RTO, although Anguil’s RTO had significant advantages over the previous model including: 95% TER (Thermal Energy Recovery), lower horsepower, lower operating temperatures, and better options for turndown and idle modes.

“Tekra went so far as to have us install a small odometer-style meter right on the front of the control panel for the Anguil RTO, showing exactly how many BTUs they were saving over their previous unit,” says Greg Blando, Service Manager for Anguil.

The Solution

The Solution

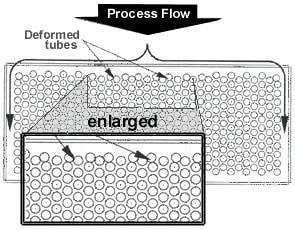

CERAMIC MEDIA RETROFIT

Tekra’s focus on achieving better energy efficiency did not end there. With a new nationwide focus on green business practices and energy costs on the rise, they again challenged Anguil to perform even better in 2009. Anguil studied the temperature charts of the RTO system and took air samples during peak VOC loading production runs and determined that the 95% TER of the system could be pushed closer to 97% without creating any adverse high-temperature conditions in the RTO. Thermal Efficiency of an RTO relates to the ceramic media inside of this type of oxidizer which captures and then utilizes energy from combustion to pre-heat the incoming, untreated airstream.

“A two percent improvement in TER may not sound all that impressive,” says Mike Scholz, Project Engineer for Anguil. “But most RTOs out there today were designed to achieve about 95% TER. The natural gas required by those systems is directly tied to that five percent of energy lost. Getting back two of the ‘lost five percent’ is actually a 40% reduction in energy lost. In practical terms, that two percent improvement in TER can translate into 40% less on your RTO natural gas bill.” In addition, the enhanced performance at Tekra put their oxidizer into a self-sustaining mode more often, meaning the fuel value in the VOC-laden exhaust gases are enough to operate the RTO and no auxiliary fuel is needed, hence fewer greenhouse gases emitted.

PROJECT PAYBACK

Because of advances in RTO ceramic heat recovery media, Anguil is routinely able to provide RTO operators like Tekra with a performance upgrade by either adding to the top of existing media beds or at times, replacing the top several layers of existing beds with new extruded ceramic media blocks. “With this type of project, payback is king,” comments Lee Kottke, a manufacturer’s rep for Anguil closely involved in the Tekra relationship. “That’s why it is exciting that Anguil can achieve this level of success with only partial media change-outs. That keeps the project cost down and payback periods very reasonable.”

There are other possible effects on project payback to consider. Deeper media beds may require the relocation of chamber instrumentation – like thermocouples. Also, higher efficiency media styles can come with increased back pressure and electrical horsepower cost. Often, however, as in the case of Tekra’s RTO, the electrical penalty is minor compared to the natural gas savings.

Gernetz said that with two coaters running a variety of coating weights and line speeds, it is difficult to get an exact dollar savings. However, prior to the media replacement their RTO often required natural gas to maintain temperature when only treating the exhausts from one coating line. Post retrofit, “the RTO rarely requires natural gas even when only one coater is operating and never when both are on,” says Gernetz. Zach added, “Jobs that were never self-sustaining before are now, so I know that the media retrofit is saving us money.” He estimates a two year payback for this retrofit.

The Result

Considering some enhancements to your RTO? Think about this:

- Up until recently, most RTOs were designed with 95% Thermal Energy Recovery (TER%) or less.

- Rule of Thumb for a self-check: If the average RTO outlet temperature is more than 100°F higher than the RTO inlet temperature, your actual TER% is probably less than 95%.

- Even a small increase in TER% can have a dramatic effect on RTO fuel usage. In some cases, a bump in TER% could eliminate RTO fuel use entirely.

- Advances in ceramic media have allowed Anguil to improve TER% in RTOs by only replacing a portion of the existing ceramic media beds, improving payback periods.

- Anguil has performed this retrofit on numerous RTOs, regardless of original manufacturer, and we offer free savings analysis for those interested.

According to Chris Anguil, President of Anguil Environmental Systems, Inc, “When I reflect on the relationship between Anguil and Tekra, it strikes me how RTOs, while such a huge leap forward in energy efficiency over previous oxidizer styles, are continuing to evolve. Advances in media and controls mean there is still room for efficiency improvements on any RTO system out there, regardless of age. Anyone owning an RTO should follow Tekra’s lead and continue to ask if they can do even better energy efficiency-wise. We applaud Tekra’s commitment to environmental compliance and energy efficiency and thank them for challenging us with this opportunity.”

Increasing Oxidizer Capacity by 80,000 SCFM

Comments Off on Increasing Oxidizer Capacity by 80,000 SCFM The Challenge

The Challenge

A recreational products company bought a three year-old manufacturing facility with an existing Regenerative Thermal Oxidizer (RTO) for the production of their outboard engines. They required emission control equipment to manage the Volatile Organic Compounds (VOCs) emitted by the solvents used in the engine painting processes. The company wanted to minimize overall costs by utilizing the existing RTO to control their emissions. However, the paint exhaust produced 80,000 SCFM (128,400 Nm3/hr), an impossible challenge for the existing RTO, which had been designed and built to control only 17,000 SCFM (27,285 Nm3/hr). Looking towards the future, the company wanted an air pollution control system capable of managing future expansion.

The Solution

Anguil’s engineering team demonstrated a solution that allowed the company to utilize the 17,000 SCFM (27,285 Nm3/hr) RTO that came with the building. By placing two 40,000 SCFM (64,200 Nm3/hr) Rotor Concentrators upstream from the RTO, the company could cost-effectively expand their operation and still achieve regulatory compliance.

The Result

The Result

This outboard engine manufacturing plant had multiple paint spray booths and ovens producing 80,000 SCFM (128,400 Nm3/hr) of exhaust air. Controlling the higher temperature oven exhaust alone would preclude the use of technologies such as VOC adsorption. However, the combined booth and oven exhaust allowed Anguil to use its integrated VOC emissions concentrator/oxidizer technology, reducing the 80,000 SCFM (128,400 Nm3/hr) paint line exhaust to 8,000 SCFM (12,840 Nm3/hr), thus incorporating the existing RTO.

This reduction was made possible when spray booth and oven exhausts were directed to the concentrator system. The VOCs from these sources are adsorbed onto zeolite that is impregnated onto a honeycomb substrate as the air passes through the substrate. These adsorbed VOCs are then desorbed off the concentrator wheel in an airflow that is one-tenth the process flow rate-resulting in a VOC concentration approximately 10 times higher than the process stream. Since the desorption air must still be controlled by an oxidizer to meet regulatory requirements, this smaller flow rate reduces the capital cost of the oxidizer. With the concentration of VOCs leaving the concentrator subsequently much higher than the original process, the operating cost of the oxidizer is also significantly reduced.

One advantage of the RTO is its low operating cost. Vertical beds of ceramic media alternately store and release heat or energy to elevate the process air temperature. Since RTOs have such high heat recovery, the process air can be heated to a value very close to the combustion chamber set-point temperature. Heat released from VOC oxidation further elevates the process air temperature to the point where the RTO is self-sustaining with no auxiliary fuel usage. The use of supplemental fuel injection (SFI) also reduces the point of self-sustained operation to a lower process inlet concentration. Operation with SFI minimizes combustion air introduction into the chamber, which further reduces operating fuel usage.

Many integrated VOC emissions concentrator/oxidizer systems employ the excess heat from the oxidizer as a source of desorption energy at the concentrator wheel. Since the RTO can be so fuel efficient, the oxidizer outlet temperature is low, limiting the use of heat recovery from the oxidizer. Because the RTO was an existing unit and the customer wanted to maintain high energy efficiency, a dedicated heat source was installed to desorb the VOCs from the concentrator wheel.

The RTO used at this facility was an existing unit that experienced several operating problems. To minimize the overall cost of the emission control for the paint system, Anguil provided mechanical and electrical modifications to allow its integration with the concentrator. The resulting benefits of the concentrator/RTO integration included:

- Additional process flow capacity: low concentrator desorption flow allowed for additional process lines to be integrated with existing RTO

- Automated and integrated control system design: including compliance with insurance/safety requirements and remote telemetry for easy system monitoring

- Prolonged equipment life: oxidizer re-insulation eliminated hot spots

- Enhanced VOC destruction: valve repair minimized leakage, while the control valve captured/oxidized the VOC “spike” typical of two-chamber RTO installations

- Reduced operating costs and NOx emissions: Supplemental fuel injection (SFI) reduces the auxiliary fuel requirement and greatly reduces the NOx output from the RTO

How to Properly Maintain and Service Your Oxidizer

Comments Off on How to Properly Maintain and Service Your Oxidizer The Challenge

The Challenge

Your air pollution control system represents a significant investment in not only initial capital but also ongoing maintenance and operation. Routine inspections performed by your staff combined with thorough maintenance plans provided by Anguil Environmental Service Technicians will ensure you get the most from your investment over the entire life of the system. Anguil has almost four decades of experience servicing a full range of oxidizer technologies, regardless of manufacturer, make or model. Following the recommendations made below will help keep your system operating both efficiently and effectively, reducing costly repairs and avoiding downtime.

The Solution

ROUTINE INSPECTIONS:

It is our goal here at Anguil to provide owners of our equipment the necessary checklists and training to comfortably perform the routine inspections with their own personnel. In the event you own another manufacturer’s equipment the checklist below may vary slightly.

Inspections include a combination of equipment checks on the “high use” items and data recording to build a history of unit performance. When performing equipment checks, operators should refer to manufacturer’s O&M Manuals for detailed procedures. For the data-gathering items, refer to historical data and note any significant changes from typical values.

WEEKLY MAINTENANCE CHECKS – TO BE PERFORMED BY THE LOCAL MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER.

- Examine air inlet filters for dirt and obstruction, clean or replace as necessary.

- Check to ensure all fan/motor guards are in place and properly secured.

- Prior to operating the system, ensure that all oxidizer doors and access panels are closed and latched.

- Check the fan(s) mounting bolts to ensure they have remained tight.

- Perform a visual inspection of the oxidizer for any loose hardware or damper linkage.

- Visually inspect the oxidizer surface looking for any new “hot-spots” which may be identified by burnt paint and other signs of overheating found on the oxidizer shell or valve housing.

- During the oxidizer’s normal operation, check for fan vibration, abnormal sounds or increased noise levels.

- Visually inspect and listen for unusual sounds during valve operation. Valves should shift smooth and evenly in both directions.

- Inspect the oxidizer fuel train for leaks or loose hardware.

- Check all temperature device read-outs to confirm temperature operation is within normal ranges.

- View pressure device read-outs to confirm operation is within normal range.

- Verify temperature chart recording device is “On” and recording data.

MONTHLY MAINTENANCE CHECKS – TO BE PERFORMED BY THE LOCAL MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER.

- Check the burner linkage and external burner components for wear or signs of loosening that could cause gradual slipping and adjustment issues with gas and air settings.

- Check fan drive belts for correct alignment, alignment and wear. The belts should have enough tension to allow only one-half-inch movement when pushed or pulled, up or down by hand. A quick check for alignment can be done by testing the tension on the inner and outer belts. The tension should be equal.

- Remove all pressure switch sensing lines, or open drain valves if available, to ensure they are clear and dry.

- Process air and exhaust fan/motor bearings should be greased, per manufacturer’s recommendation. Rotate the shaft slowly by hand while applying the grease. Avoid over-greasing as it can damage the bearing seals.

- Drains or weep holes on all fan motors should be checked for debris and cleaned as necessary.

- Verify oil level of compressed air lubricator, add as necessary.

- Verify burner flame visually at burner or system Peep-Sight for color and intensity. The flame should typically be “Blue” with “Orange/Yellow” tips. The flame strength should not be “Lazy”, you should verify intensity at several different firing rates.

SEMI-ANNUAL MAINTENANCE CHECKS – CAN BE PERFORMED BY MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER OR AN ANGUIL ENVIRONMENTAL SERVICE TECHNICIAN.

SEMI-ANNUAL MAINTENANCE CHECKS – CAN BE PERFORMED BY MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER OR AN ANGUIL ENVIRONMENTAL SERVICE TECHNICIAN.

- The interior of the oxidizer should be inspected. While inside, inspect the insulation for signs of deterioration, damage or gaps. Use extreme caution when entering or exiting the oxidizer to avoid damaging the door or the door threshold insulation (if applicable). Internal entry to be made by qualified personnel per site safety requirements.

- Clean the inner lens of the burner view port with a soft, dry cloth.

- Check the ceramic media for buildup of particulate or residue and visible damage.

- Before closing access doors, inspect the gaskets replacing or repairing as necessary to maintain a leak free seal.

- Visual inspection (only) of poppet valve shafts, seats, and disks. Caution: This should be performed by trained / authorized personnel only, after adhering to all lock-out / tag-out safety precautions. Note:The flow control valves may shift without warning if the mechanical safety pins are not installed.

- Remove the UV scanner and clean the view lens with a lint free cloth.

- Replace the spark igniter.

- Inspect the exterior of the burner for damage or areas showing excessive heat.

- Inspect all fan flex joints and replace as necessary

- The T-dampers and linkage (if applicable) should be inspected for proper operation and the linkage checked for tightness and lubrication at appropriate points.

- Verify burner flame visually at burner or system Peep-Sight for color and intensity. The flame should typically be “Blue” with “Orange/Yellow” tips. The flame strength should not be “Lazy”, you should verify intensity at several different firing rates.

- Review past alarms for identification of areas requiring specific attention to eliminate possible future alarms.

YEARLY INSPECTION: PREVENTIVE MAINTENANCE EVALUATIONS (PMES):

The Anguil Preventive Maintenance Evaluation (PME) is a two to three day thorough evaluation of your system performed by a qualified Anguil Field Service Engineer. Typically, PMEs are scheduled on an annual or semi-annual basis. It does require the system be cooled down and not running for one day to complete the internal inspection. On the second day of a PME the availability of process airflow is recommended in order for the system to be inspected under normal operating conditions.

The inspection is based upon a comprehensive checklist followed up with a written formal report for your records. The formal reports are an important component of a proper maintenance / record-keeping program and are often very helpful when working with local regulatory agencies. In some cases, record keeping and regular maintenance are required as a component of an air permit. The checklist is broken down into the following four areas of your system:

- Mechanical: An external and internal inspection of the oxidizers mechanical components will be performed. This includes items such as: ductwork, valves, linkage, heat exchanger, reactor, fan, motor assembly, burners, catalyst, stack & observation ports.

- Electrical: The electrical components will be inspected and electrically tested to insure that they are functioning properly. This includes: switches, lights, relays, timers, controllers, recorders, motors, starters, actuators, disconnects, and wiring. Additionally, the system’s “Safety Circuit” will be tested for proper operation and a new spark igniter(s) installed.

- Process Control Loops: The temperature and pressure control loops will be inspected and tested to verify correct operation and sequence. This entails a visual inspection and adjustment of the air/fuel mixture ratio of the burner, if necessary. Also, an operational review of various controllers, actuators, thermocouples, pressure switches and variable speed drives will be performed. We will also evaluate the system (or catalyst) ready circuit, the inlet and atmospheric bypass damper circuits, the warning alarm circuits, and the shutdown alarm circuits.

- Oxidation Efficiency Test: If requested – an optional oxidation efficiency test can be performed by using portable detector units or collecting 1-Hour process inlet / outlet samples for laboratory analysis. This service keeps you alert of any potential problems related to your system’s Destruction Rate Efficiency (DRE) and is ideal as a pre-test to help eliminate “surprises” during expensive formal compliance testing.

Upon completion of a PME you will receive a formal evaluation report detailing the current condition of your oxidizer as well as our recommendations for improving performance, efficiency, reliability and safety.

ADDITIONAL TESTING AND MAINTENANCE IDEAS TO CONSIDER:

Repeat Training Sessions: Your maintenance team may require additional training sessions as a refresher or due to employee turnover. Anguil will travel to your site and perform follow-up training sessions, often coupled with any of the inspection visits listed above.

Catalyst Maintenance: If your system includes catalyst – Anguil can help you remain in compliance and build a catalyst performance history with regular testing of your catalyst. Regular evaluation is key to maintaining catalyst performance. A standard laboratory activity test should be performed yearly, with additional follow-up testing as necessary. A formal evaluation report will be provided. Additionally, Anguil can provide other catalyst services such as catalyst rejuvenation, catalyst replacement, and also a “catalyst buy-back” program for spent catalyst.

The Result

For further information please contact the Anguil Service Department, we offer all of the services listed and more on any make or model oxidizer system! Programs can be purchased individually or grouped into a custom designed service plan.

Heat Exchanger Retrofit

Comments Off on Heat Exchanger Retrofit The Challenge

The Challenge

A manufacturer of insulation films for the electronics industry needed to evaluate the capabilities of four existing oxidizers that treated emissions from its coating lines. The company was concerned that, due to oxidizer deficiencies, it would not meet regulatory requirements. The oxidizers had been manufactured by two different companies. One of them was no longer in business and the other was unable to provide an adequate solution. The customer needed an experienced engineering company that could accurately identify the oxidizers’ deficiencies and provide quality repairs.

The Solution

After evaluating the service capabilities of several equipment manufacturers and engineering consultants, the company chose the full-service solution of Anguil Environmental Systems. Anguil’s comprehensive preventive maintenance evaluations of the four oxidizers provided detailed recommendations to improve the oxidizers’ performance. The most urgent recommendation saved the company thousands of dollars in operating costs and put the company in compliance.

The Result

Anguil’s rigorous 75-point Preventive Maintenance Evaluation (PME) discovered minor problems with three of the units and a major problem with the largest oxidizer, a 13,500 SCFM (21667.5 Nm3/hr) catalytic oxidizer. Anguil’s recommendations for the three smaller oxidizers greatly improved their safety and performance. Many of the cost-saving suggestions were easily performed by the plant’s in-house maintenance staff. However, the larger oxidizer required more intensive application engineering and a comprehensive air pollution control solution.

The 13,500 SCFM (21667.5 Nm3/hr) system had both a primary and secondary heat exchanger. The primary heat exchanger recovers energy from the combustion chamber exhaust and transfers it to the incoming process air stream to reduce fuel consumption. The secondary heat exchanger recovers additional energy from the primary heat exchanger outlet flow and uses this energy to preheat an air source used in the process. In this case, the secondary heat exchanger is integral to the plant’s coating process; it is used to heat the tower dryer of the AISCO coating machine. The plant engineers had noticed a steady decline in the heat available from the oxidizer and secondary heat exchanger. By the time of Anguil’s investigation, the oxidizer took up to six hours to sufficiently heat the coater before production could begin. During the six hours of warm-up, the oxidizer had to be supplied with natural gas. This tremendous fuel consumption led to extremely high operating costs.

Anguil performed a destruction efficiency test on the oxidizer when the coated web used 100% toluene as a solvent. Under normal conditions, an oxidizer of this type should have little difficulty in attaining better than 98% destruction efficiency. Due to the airflow bypassing the combustion chamber, the oxidizer was achieving only 93.6% destruction efficiency and did not meet regulatory emission requirements.

Replacing the oxidizer would have drastically interrupted the customer’s manufacturing schedule and resulted in capital cost increases that were unacceptable. Anguil’s solution, however, eliminated any production disruptions by performing repairs and design enhancements over several process downtimes. The first step was to immediately replace both the primary and secondary heat exchangers. Anguil designed, manufactured and installed replacement exchangers for this oxidizer. The dismantling, removal and replacement of the exchangers were performed over a three-day weekend when the customer had a scheduled plant shutdown.

The replacement heat exchangers significantly improved the performance of the 13,500 SCFM (21667.5 Nm3/hr) oxidizer. Previously, the oxidizer had to be run for up to six hours to meet the necessary temperature at a fuel cost estimate of $266/per startup. The process air temperature required for the coating machine is now achieved in one hour. The improved efficiency results in operating cost savings of approximately $230 per startup and up to $30,000 annually. The economic impact of the retrofitted heat exchangers went beyond fuel savings; the improved start-up time has reduced plant downtime and increased worker production. The new heat exchangers have also improved the destruction efficiency of the oxidation system and put the company in compliance.

Anguil’s analysis detailed other cost saving suggestions for the company, including:

- Ductwork adjustments for more efficient oxidizer operation

- Heat exchanger maintenance suggestions for all four oxidizers

- Review of safety controls and upgrade recommendations

- Variable Frequency Drive for the fan on the largest oxidizer to accommodate airflow changes more efficiently

- Burner maintenance suggestions

Anguil also performed airflow analysis of all processes. This information will help the company plan for future growth with additional coating lines.

The retrofitted system is currently exceeding the regulatory requirements and providing an efficient heat source for the coating lines. The Anguil service team’s expert troubleshooting and quality turnkey solution capabilities have led to another satisfied customer.

Crafting Your Oxidizer Maintenance Plan

Comments Off on Crafting Your Oxidizer Maintenance PlanThe Challenge

OXIDIZER SERVICE SERIES: PART 2

Having documentation and spare parts readily available is a great start to being proactive and maintaining effective system operation, but what if you could catch a potential issue before it becomes one? Whether it is still on the drawing boards or has been on site for years, your air pollution control system represents a significant investment and a long-term commitment to environmental compliance. A well-crafted maintenance plan for your oxidizer will allow you to get the most from your investment over the entire life of the system.

The Solution

Many will come to this article hoping for a one-size-fits-all checklist for maintaining an oxidizer system. As a company that offers

- Gather all the system documentation as listed in Part 1 of our Oxidizer Service Series. Make sure this documentation is readily available to both system operators and service providers.

- Stock the recommended spare parts for your oxidizer system (more on this in Part 3 of our Oxidizer Service Series)

- Establish a monthly checklist of system inspection points and make sure your own operators are comfortable with what to look for and how to record their findings

- Maintain an operator log book or journal of system issues

- Obtain a yearly Preventive Maintenance Evaluation (PME) from an independent or third party oxidizer service provider such as Anguil

- Establish remote access capability to your system’s controls from an oxidizer service provider such as Anguil

Some may choose to take this basic recommendation for a maintenance plan, stop reading here, and run with it. We would agree that anyone complying with all of the steps as outlined above is indeed making a defensible effort at maintaining their oxidizer system; however, having an Oxidizer Service Provider like Anguil visit your site for a couple days could jump-start the implementation of such a plan.

Maintenance Plan Drivers

The following drivers make the decision to implement an oxidizer maintenance plan imperative:

Production Uptime – An informed staff and a transparent maintenance plan will allow for maximum production uptime, prevent costly shutdowns, and enable a prepared response to operational irregularities.

Compliance with Environmental Regulations – Being out of compliance can be costly and a public relations disaster. The language in many air permits requires operators to stock spare parts, keep historical service documentation, and maintain the system according to the manufacturer’s recommendations.

Compliance with Safety Regulations – Compliance codes often require that safety checks be performed on an annual basis for this class of equipment. Anguil incorporates these safety checks as a part of our 75+ point Preventative Maintenance Evaluation.

Operating Cost Reduction – A good maintenance plan will often pay for itself by ensuring that your oxidizer system is running at peak efficiency and with minimal downtime.

Maintenance Plan Building Blocks

The right maintenance plan for one company might not be the right plan for another. Anguil considers the following to be the building blocks of a comprehensive maintenance plan that can be customized to fit the needs of any operating context.

- System Documentation – Gather all your system documentation in one binder as outlined in Part 1 of our Oxidizer Service Series. Make sure this documentation is readily available to both system operators and service providers. We recommend storing

inside the control panel.

- Recommended Spare Parts Package – An Oxidizer Service Provider like Anguil can identify the critical components, recommended components, and convenience items that you should stock to maintain smooth operation of your system and limit production down time.

- Annual Preventive Maintenance Evaluation (PME) – Often done by an Oxidizer Service Provider like Anguil. This is not just our advice. This is rapidly becoming part of Permit Codes and Compliance – both environmental codes and safety codes. Anguil’s standard PME program includes a 2-3 day service visit utilizing a 75+ point checklist to ensure your oxidizer is meeting air pollution control standards and is followed by a formal report for your maintenance records.

The next four options can be performed in conjunction with a PME visit or ordered separately as stand-alone services.

- Destruction Removal Efficiency (DRE) Check-Ups – An oxidizer service provider like Anguil can check the VOC destruction efficiency of your system with portable testing equipment or via laboratory analysis of air samples. This service keeps you on track with system performance and verifies compliance. It is ideal as a pre-test to help eliminate “surprises” during expensive formal compliance testing.

- Repeat Operator Training – Maintenance personnel take pride in servicing the equipment if they are familiar with the operation. Years one and two of an oxidizer’s life can present different maintenance challenges than years three through fifteen. Repeat training can keep operating personnel prepared to meet evolving service needs. Repeat Operator Training is showing up in the NFPA codes as well.

- Catalyst Services – At the heart of every Catalytic Oxidizer System is the catalyst bed. Properly maintained, the catalyst bed can provide years of high VOC Destruction at temperatures well under those required for thermal oxidation. Anguil offers a full program of catalyst services including Evaluation and Testing, Rejuvenation, Replacement, and the purchase back of “spent” catalyst for recycling.

- Split Preventative Maintenance Evaluations – Some facilities have little precious downtime for system repairs, so they want to be prepared with the right parts and contractors to act on repairs immediately when their downtime occurs. They may elect a Split-PME scenario, which starts with a one day system evaluation visit by a Field Service Engineer. A second visit is scheduled and the Field Service Engineer returns with all parts and materials identified in the system evaluation, prepared to execute on the service recommendations immediately.

- Semi-Annual Preventative Maintenance Evaluations – For some, the yearly comprehensive Preventive Maintenance Evaluation is not enough. Overall system balancing, operational cost verification, and inventory of spare parts should be conducted semi-annually. Depending on the complexity of your system, you may wish to contact Anguil to perform this service for you.

- Remote Login Capability – Remote log-in could be your lifeline in emergency situations. Establishing this capability is one of the most important things you can do when devising your maintenance plan. Remote Access Capability has recently become a game changer in the oxidizer service world. For the companies and oxidizer systems we service, when the capability is in place, it is both a lifeline during system upsets as well as a “force-multiplier” when our Field Service Engineers are on a particular site. One need only walk into our Service Manager’s office during a live-connection event and see two or three additional heads observing the system operation in real-time while conversing directly with our Field Service Engineer on site. It is akin to getting the experience and knowledge of several engineers on site for the price of one. In today’s world, no oxidizer end-user should be left behind without this critical safety net in place. Don’t wait for an emergency to find out the connection isn’t there. Anguil can also perform routine operational checks remotely and potentially identify developing service issues proactively for a fraction of the cost of an on site visit. Adding this service quarterly is rapidly becoming a popular option. For those with this feature, make sure to regularly test your connection.

- Operating Cost Review – Do you know exactly how much your system should be costing you to run? Are you getting the most for your operating dollars? Anguil offers an Operating Cost Review Program that can answer these questions for you and provide cost savings recommendations tailored for your oxidizer system.

- Operator Log Book – Thorough service history documentation, including a historical account of daily, weekly, and annual inspections, is often an air permit requirement. Like a doctor’s medical records, a comprehensive operator log will help diagnose operating irregularities and could prevent costly malfunctions down the road.

- Weekly Walk-By Inspections – Typically performed by your own personnel. An Oxidizer Service Provider like Anguil can custom design weekly inspection checklists for your specific oxidizer system.

- Deeper Monthly/Maintenance Day Inspection Checklists – For our Monthly Inspections program, we provide a list of the system components needing inspection, independent verification, and/or calibration on a monthly basis. Our goal is to train your maintenance teams to feel comfortable performing the monthly checks on their own.

- Custom Maintenance Plans – Multi-Year and Multi-Facility Packages

- Developing a custom maintenance plan with an Oxidizer Service Provider can result in a strong service relationship built on trust and long-term oxidizer expertise. Anguil’s custom maintenance plans include multi-year deals for individual plants or across multiple facilities. Custom multi-year and multi-facility maintenance plans can offer numerous benefits:

- Smooth Equipment Turnover Between Project Engineering and Production Engineering Teams – Many oxidizer systems are purchased via a project engineering team who then must turn the equipment over to production teams. This hand-off can proceed much smoother if the production team sees that there is a service agreement already in place.

- Reliable Budgeting – Having a multi-year service plan can take some guesswork out of operational budgeting.

- Consistent Service History – even as plant personnel may turn over.

- Knowledge Sharing – Maintaining service history at the plant level can be difficult enough. A corporate level maintenance plan can become a conduit for improved knowledge sharing between plants.

- Uphold Corporate Values – Environmental Compliance is often part of your Corporate Level Mission Statement.

Reliability Centered Maintenance

Anguil recently participated in a three-week-long Reliability Centered Maintenance (RCM) evaluation of an oxidizer system. This particular system treats the exhaust from a critical production line in one of the most highly regulated areas of the country. RCM is a landmark maintenance concept defined in John Moubray’s book Reliability-Centered Maintenance as “a process used to determine the maintenance requirements of any physical asset in its operating context.”

For this RCM evaluation, a team of Anguil Personnel along with the facility’s maintenance personnel, equipment operators, electrical controls specialists, and EHS staff was assembled and guided by an RCM facilitator. The team went line-by-line through the oxidizer electrical schematics, the sequence of operation, the control programs and the environmental permit requirements to define the system’s functions and possible functional failures. Using the framework of the RCM program, the team generated lists of potential redesigns, required procedures, a compulsory spare parts program, and implementation reports for the system as a whole. This was no small task — the final report was over 400 pages long! The evaluation was a significant investment in both money and manpower for both Anguil and the company involved.

Our two biggest takeaways from this experience were:

- This is the level of training that operators of oxidizer systems deserve but rarely get

- The importance of “Operating Context” in determining a suitable approach to long term maintenance of a particular oxidizer system

To further illustrate the idea of operating context, consider that oxidizers today are being installed into production scenarios where they:

- May be allowed to be offline for several weeks or months in a given year

- May force the end-user to stop all production immediately when offline, in some cases triggering “Notices of Violation” and fines upon any upset condition

- May be treating exhaust gas streams that are immediately dangerous to life and health

- May be the sole source of heat for the process to which they are attached

Each one of these different operating contexts can play a major role in the final determination of an appropriate maintenance plan for a particular oxidizer system.

Not everyone can afford to go to the lengths of implementing a formal RCM maintenance program for their oxidizer system. There are also plenty of industries with enough historically acquired experience where such an effort may not be required. However, an effective and custom maintenance plan adhering to minimum requirements can be crafted with help from an Oxidizer Service Company like Anguil and customized to your particular operating context. Such a program will prolong the life of your equipment while staying within the restraints of an operating budget.

The Result

In summary, there is no one-size-fits-all solution for crafting a quality oxidizer safety and maintenance program. At Anguil, we strive to offer a full menu of reliability services to make crafting even the most basic maintenance plan an essential and affordable investment. Our experienced service personnel look forward to assisting you in designing the smartest maintenance program for your company.

This is the second of four parts in Anguil’s Oxidizer Service Series. We encourage you to also view Part 1: Better Maintenance Starts With Better Documentation as well as Part 3: Stocking Spare Parts for Your Oxidizer System and Part 4: Oxidizer System Optimization.

Catalytic Oxidizer Catalyst Replacement

Comments Off on Catalytic Oxidizer Catalyst Replacement The Challenge

The Challenge

A New Jersey pharmaceutical company purchased a thermal incinerator to treat the heptane and hexane exhaust from their capsule wash system. The thermal incinerator’s “tubular” design was modified with a catalyst bed in order to reduce the system’s operational costs. Unfortunately, when operating in the catalytic mode, the oxidizer failed to provide the required 95% destruction efficiency of non-methane hydrocarbons required by the New Jersey Department of Environmental Protection. These odorous emissions led to neighbor complaints and an EPA consent decree, complete with a $175,000 civil penalty. Although the company was proactive in trying to solve the emission problem, the EPA stipulated penalties of $2,500 for every day the violation existed. The original equipment supplier attempted to rectify the problem to no avail and the pharmaceutical company remained in violation of their New Jersey air permit.

The Solution

After meeting with several potential suppliers, the company selected was Anguil Environmental Systems, Inc. Anguil’s track record with catalytic systems, knowledge of catalyst and engineering strength made them the most likely candidate to tackle the VOC problem successfully.

The Result

The Result

Anguil successfully retrofitted the non-compliant system and brought the company into EPA compliance. The first step in Anguil’s approach was to examine the reason for catalyst nonperformance. There were several potential reasons for catalyst failure. The possibility of catalyst masking or the presence of a poisoning agent (i.e. sulfur, phosphorus, heavy metals) within the VOC-laden stream was examined; however, no significant levels of any of these agents were detected.

The second possibility was that the industrial process stream was being allowed to pass through the oxidizer before it was brought to proper operating temperature. This would result in the coating of the stainless steel rings with the heptane and hexane hydrocarbons. If this was the case, when the unit was brought to the proper operating temperature, oxidation would occur on the catalyst, leaving a carbon deposit. This type of carbon deposit would result in decreased destruction efficiency and the formation of incomplete combustion products. No signs of these carbon deposits, known as coking, were detected.

Having eliminated these suspects, Anguil conducted a laboratory performance test that indicated the reason for catalyst failure: the catalytic stainless steel rings lacked the proper surface area to achieve the quoted destruction efficiency. This performance test revealed that there was less than 50% destruction efficiency of a propane and propylene test stream. This is an excellent indicator of catalyst failure or inactivity.

Anguil modified the system design to accommodate a honeycomb catalyst. The monolithic catalyst Anguil chose was a 300 cell-per-square-inch ceramic substrate. An alumina washout was used to deposit large quantities of precious metal (i.e. platinum, palladium, rhodium). The surface area of this replacement catalyst is more than 100 times greater than that of its stainless steel counterpart. (Note: a cubic foot of this monolithic catalyst contains more surface area than that of a football field.) The oxidizer was equipped with a new reactor section to house the nine cubic feet of monolithic catalyst. A 95% destruction efficiency guarantee was provided along with the system retrofit.

A follow-up Flame Ionization Detector (FID) was also performed on this retrofit and a carbon filter was added to eliminate methane readings. The FID test results indicated a VOC inlet concentration of 943 ppm and an oxidizer outlet concentration of less than 20 ppm. The company is now EPA-compliant 97.8% destruction efficiency. Anguil is well-known for providing VOC control systems but in this case, they demonstrated their ability to provide answers where others had failed.

Better Maintenance Starts with Better Documentation

Comments Off on Better Maintenance Starts with Better DocumentationThe Challenge

OXIDIZER SERVICE SERIES: PART 1

Part of properly servicing your oxidizer system is maintaining the design documentation associated with that system. When it comes to oxidizer design, National Fire Protection Association (NFPA) standards are considered good practice, and those same standards include requirements that should be used for ongoing oxidizer maintenance and system documentation.

The Solution

The following are critical design documents oxidizer users should preserve that contain information required by the NFPA to implement an overall system reliability plan. Anguil uses the same documents to build and maintain information to offer value-added service on anyone’s oxidizer system, regardless of the original manufacturer. The documents listed with an asterisk (*) are the three most important documents to have on hand and you should always have print copies inside your control panel.

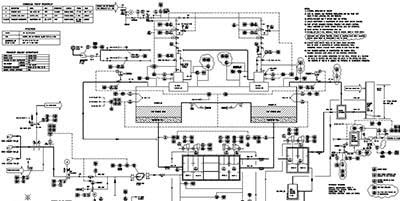

- Process and Instrumentation Diagram (P&ID):The P&ID is the command drawing that summarizes instrumentation, safety devices, operational limits, and control loops. The P&ID typically provides the oxidizer component tag numbers, as well as the number and type of process exhaust pick-ups for the system. The system utility requirements and performance parameters can be listed as well.

- Electrical Schematics:The electrical schematics provide the detailed connectivity of the entire system and is an important tool used for system troubleshooting. It is critical that the electrical schematics are not only kept readily available, but also revised to keep up with system changes.

- Sequence of Operation / List of Set Points & Alarm Conditions:The sequence of operation is a step-by-step description of how the oxidizer is designed to operate. It includes: how it starts, how it brings process exhausts on-line, how it maintains airflow and temperature control, and how it safely shuts down. Set points and alarm conditions of the system are also included in this document. It is important to note that this documentation is required per the National Fire Protection Association’s NFPA 86: “Wiring diagrams and sequence of operations for all safety controls shall be provided” (From NFPA 86: Standard for Ovens and Furnaces, 2019 Edition – Section 4.1.1.2).

- Programmable Logic Controller (PLC) Program: If your system requires a PLC, we recommend you keep a fully documented copy of your PLC program for your records. It is important to know that some oxidizer suppliers may be reluctant to release this information to system end-users because PLC programs can include proprietary control schemes. However, with a signed confidentiality agreement in place, end users should be able to obtain this code. If your oxidizer manufacturer is no longer in business, it is possible to upload the program directly from the PLC, but it may be undocumented and you may need an oxidizer service provider to re-enter the code documentation. Information on Anguil’s PLC programming capabilities can be found here.

- Human Machine Interface (HMI) Program:The HMI (Operator Interface / Operator Touch Screen) is the operator’s window into the workings of the oxidizer’s PLC. The HMI program goes hand-in-hand with the PLC program to control your oxidizer system by displaying data points from the PLC along with set points and tuning parameters the operator will be allowed to adjust from the HMI. The HMI also provides system status messages and/or alarm messages based on the PLCs outputs. A failed display can leave you essentially blind when it comes to operating your oxidizer system safely. If this happens at an inopportune moment, you want to be prepared to download your HMI program to a replacement display from your spare parts inventory.

- Expected Pressure-Temperature Profile:This is one of the more obscure documents to obtain, however, it is pivotal in the development of a reliability plan for your system. Obtaining this information can be as simple as a small table on the P&ID giving the expected temperature and pressure value at various points throughout the oxidizer. It is critical to know your pressure point values in order to set up a regular inspection plan for your maintenance personnel. Ideally, you should have a table showing expected pressure and temperature data at the common process exhaust airflow amounts your production requires. If this is unknown, ask your system provider to provide data for two conditions: at full-oxidizer airflow capacity and at half-oxidizer airflow capacity. Once provided this information, you will be able to approximate the points in-between when establishing your customized inspection checklists.

- Permit Compliance Documents:Compliance documentation requirements vary greatly across local, state, and federal agencies, making it difficult to provide generalized recommendations appropriate for all operation scenarios. At a minimum, Anguil highly recommends summarizing your permit compliance documentation requirements within a single, concise document that includes minimum and operating temperatures and bypass limitations. This document will keep all parties aware of the key compliance parameters to monitor and record with respect to your oxidizer system.

- Bill of Materials / Recommended Spare Parts Lists:Finally, a complete bill of materials for your oxidizer system will allow you to obtain the parts you need to maintain system operation. Ideally, the parts listed in the Bill of Materials would be further categorized as “Critical Spare Parts,” “Recommended Spare Parts,” “Consumable Spare Parts,” “Convenience Items,” “Long Lead Time Components,” etc. This allows operators to make an informed decision on the type and quantity of spare parts to stock based on specific production and compliance requirements. Some air permits actually require that critical spare parts be kept on hand. More detailed information on these categories can be found on the Spare Parts section of our website.

ADDITIONAL INFORMATION

ADDITIONAL INFORMATION

Here are some additional highlights regarding system documentation from the current edition of NFPA 86 Standard for Ovens and Furnaces 2019 Edition:

4.1.1.1 Plans shall be drawn that show all essential details with regard to location, construction, ventilation, piping, and electrical safety equipment. A list of all combustion, control, and safety equipment giving manufacturer and type number shall be included.

4.1.1.2 Wiring diagrams and sequence of operations for all safety controls shall be included.

7.3.3 Operating instructions that include all of the following shall be provided:

(1) Schematic piping / wiring diagrams

(2) Startup procedures

(3) Shutdown procedures

(4) Emergency procedures

(5) Maintenance procedures

7.3.4 When the original equipment manufacturer no longer exists, the user shall develop inspection, testing, and maintenance procedures.

The Result

This is the first of four parts in Anguil’s Oxidizer Service Series. We encourage you to also view Part 2: Crafting Your Oxidizer Maintenance Plan as well as Part 3: Stocking Spare Parts for Your Oxidizer System and Part 4: Oxidizer System Optimization.

The Challenge

The Challenge Optimization Strategies

Optimization Strategies FOCUS ON COMBUSTION AIR

FOCUS ON COMBUSTION AIR The Challenge

The Challenge The Challenge

The Challenge

The Solution

The Solution The Challenge

The Challenge The Result

The Result The Challenge

The Challenge SEMI-ANNUAL MAINTENANCE CHECKS – CAN BE PERFORMED BY MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER OR AN ANGUIL ENVIRONMENTAL SERVICE TECHNICIAN.

SEMI-ANNUAL MAINTENANCE CHECKS – CAN BE PERFORMED BY MAINTENANCE STAFF OF THE EQUIPMENT OWNER/USER OR AN ANGUIL ENVIRONMENTAL SERVICE TECHNICIAN. The Challenge

The Challenge inside the control panel.

inside the control panel. The Challenge

The Challenge The Result

The Result

ADDITIONAL INFORMATION

ADDITIONAL INFORMATION