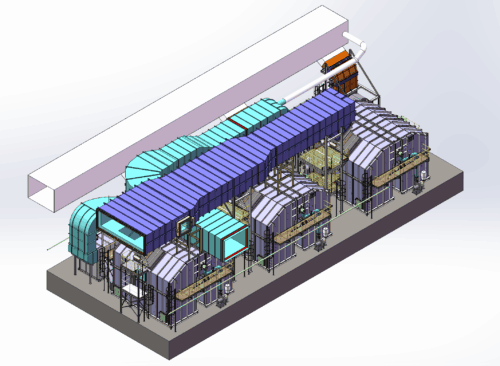

Australian Mine Selects Anguil RTO for New South Wales VAM Project

Comments Off on Australian Mine Selects Anguil RTO for New South Wales VAM ProjectMilwaukee, Wisconsin – January 29, 2026 – Anguil Environmental Systems, Inc. (Anguil) is pleased to announce that it has been awarded a contract for the supply and manufacture of a Regenerative Thermal Oxidizer (RTO) for the abatement of Ventilation Air Methane (VAM) for GM3’s Appin Mine at Douglas Park, New South Wales, Australia. This highly anticipated project will serve as a demonstration plant to the Australian underground coal mining industry, providing valuable insights and data to inform future projects for the abatement of VAM in Australia. Construction is underway with commissioning scheduled for 4th quarter 2026. The project reflects GM3’s long-term commitment to delivering sustainability across all aspects of their business.

The Anguil RTO is a proven VAM control device capable of handling a range of methane levels. Anguil has successfully supplied over 25 RTOs worldwide at coal mines. The Anguil RTO design is field proven to guarantee 98+% methane destruction while achieving high thermal efficiency. The Anguil RTO is a modular design and scalable to allow for multiple RTOs to be used in parallel to treat the largest of vent shaft flows.

Anguil will execute the project in collaboration with our Australian VAM RTO partner, Gasco Pty Ltd (Gasco). Based in Melbourne, Gasco will provide local engineering, supervision, service and maintenance support. Gasco has been providing methane abatement systems to coal mines already through their portfolio of products which include coal mine drainage gas flares – both enclosed and elevated.

For further GM3 project information, read their article.

Anguil Returning to Exhibit at NAATBatt Annual Meeting & Conference

Comments Off on Anguil Returning to Exhibit at NAATBatt Annual Meeting & Conference

Hosted by NAATBatt International, the trade association for advanced battery technology in North America, NAATBatt 2026 will focus on the rapid build-out of advanced battery manufacturing in North America. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various battery applications.

Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Tucson!

Anguil to Exhibit at JEC World 2026

Comments Off on Anguil to Exhibit at JEC World 2026Anguil Environmental will be at the JEC World 2026 in Paris from March 10th-12th, 2026 displaying the latest technologies and techniques being applied in this industry.

Specific Air Pollution Control Systems are used for the treatment of emissions from carbon fiber and composite manufacturing that not only ensure compliance but can also reduce the cost of material processing. Attendees of the upcoming JEC will have the opportunity to learn what clean air techniques are working and how they relate to manufacturing costs.

Anguil provides fully integrated systems for air pollution abatement to carbon fiber operations located throughout the world. We are intimately familiar with the capture, control, and compliance hurdles that processing plants face with regard to Volatile Organic Compounds, Hydrogen Cyanide (HCN), Ammonia, Silicone, Nitrogen Oxides (NOx), and odorous emissions.

We have developed the most advanced air pollution control technologies currently used for carbon fiber processes. The proprietary designs offer high destruction efficiency, low greenhouse gas output, and energy recovery options for powering process systems.

- Process Emissions: Oxidation Ovens & Carbonization Furnaces; Hydrogen Cyanide (HCN), Ammonia (NH3), Volatile Organic Compounds (VOCs), Tar, Silica

- Abatement Equipment: Regenerative Thermal Oxidizers (RTOs), Multi Staged Direct Fired Thermal Oxidizers (MS-DFTO), Secondary Heat Recovery, Particulate Control

- Operational & Maintenance Considerations: Designed to Maximize Up Time, Energy Efficiency, and Heat Return to Process. Minimize Maintenance Time & Costs.

Our company is intimately familiar with the capture, control, and compliance hurdles that processing plants face.

Visit Anguil in the United States Pavilion to learn more and speak with experts about your specific needs. Anguil team members will be on hand throughout the conference to explain how these energy-efficient oxidizer systems are revolutionizing the industry and why they have the highest environmental performance on record. Interested in setting up a meeting with one of our sales engineers? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your needs.

Registration to attend JEC World 2026 is available here.

Anguil to Exhibit for the First Time at Longwall 2026

Comments Off on Anguil to Exhibit for the First Time at Longwall 2026

Hosted by Informa Australia, the nation’s leading event organizer, Longwall 2026 will feature some of the biggest names in the mining industry today. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various mining applications.

Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in New South Wales!

Anguil to Exhibit at International Battery Seminar 2026

Comments Off on Anguil to Exhibit at International Battery Seminar 2026

Anguil team members will be on hand throughout the event to speak with attendees about the pollution abatement technologies and techniques being applied on various battery-related applications. Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We look forward to seeing you in Orlando!

Additional information on Anguil’s experience in this exciting industry is located here.

Anguil Environmental to Return to SESHA in April

Comments Off on Anguil Environmental to Return to SESHA in April

Anguil understands the high technology industry’s need for up-time, increased production, and environmental compliance. Visit us to learn more about how our solutions can impact your unique application. Interested in setting up a meeting with one of our sales engineers? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your needs.

Visit www.sesha.org for more details. Looking forward to seeing you in Tempe!

Anguil Returning to Exhibit at Biogas Americas

Comments Off on Anguil Returning to Exhibit at Biogas Americas

Hosted by the American Biogas Council, Biogas Americas is the largest biogas conference and tradeshow in North America. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various biogas applications.

We’ll be at the Colorado Convention Center throughout the event. Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Detroit!

Anguil Exhibiting Once Again at Environmental Trade Fair and Conference (ETFC)

Comments Off on Anguil Exhibiting Once Again at Environmental Trade Fair and Conference (ETFC)

Anguil has long been a pollution control equipment leader in the Natural Gas Production and Refining and Petrochemical industries. In fact, Anguil is the largest supplier of oxidizer technologies to the natural gas industry. Our solutions, including Regenerative Thermal Oxidizers (RTOs), Direct Fired Thermal Oxidizers (DFTOs), and Vapor Combustors, are engineered with careful consideration given to the design and material selection to avoid corrosion, equipment failures and non-compliance. Anguil oxidizers are built with quality materials of construction and engineered to withstand difficult streams and often remote installations. With additional expertise in Industrial Wastewater Treatment solutions as well as local representatives and service personnel, Anguil is positioned to be a single-source provider of air and water pollution control needs for the greater Texas region.

Held at the Henry B. Gonzalez Convention Center, Anguil engineering experts will be onsite in Booth #353 to discuss how our innovative solutions can meet the needs of your application. More information on the trade show and attendee registration can be found here.

We look forward to seeing you there!

Anguil to Exhibit for the First Time at ChemE Show

Comments Off on Anguil to Exhibit for the First Time at ChemE Show

Anguil Environmental is excited to announce our attendance for the first time as an exhibitor to the 2026 ChemE Show this June 9th through 10th in Houston, Texas.

Powered by ACHEMA, ChemE Show 2026 will feature some of the biggest names in the chemical industry today. Anguil has supplied hundreds of pollution control systems at a wide variety of chemical processing applications including specialty chemical and petrochemical operations that process organic and inorganic raw materials. Many of our air pollution abatement installations are applied on the most challenging applications controlling halogenated streams containing chlorinated, brominated, and fluorinated compounds often found at these facilities.

Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various chemical applications. Hosted at the George R. Brown Convention Center, we’ll update this article with our booth number once it is finalized. Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Houston!

Anguil to Exhibit for the First Time at International Mining & Resources Conference

Comments Off on Anguil to Exhibit for the First Time at International Mining & Resources Conference

As Australia’s International Mining Week, IMARC will feature some of the biggest names in the mining industry today. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various mining applications.

Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Sydney!