Anguil Environmental to Return to SESHA in April

Comments Off on Anguil Environmental to Return to SESHA in April

Anguil understands the high technology industry’s need for up-time, increased production, and environmental compliance. Visit us at Booth #10 to learn more about how our solutions can impact your unique application. Interested in setting up a meeting with one of our sales engineers? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your needs.

Visit www.sesha.org for more details. Looking forward to seeing you in Tempe!

Anguil to Exhibit for the First Time at Biogas Americas

Comments Off on Anguil to Exhibit for the First Time at Biogas Americas

Hosted by the American Biogas Council, Biogas Americas is the largest biogas conference and tradeshow in North America. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various biogas applications.

We’ll be in Booth #126 at the Colorado Convention Center throughout the event. Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Denver!

Anguil to Exhibit for the First Time at AISTech

Comments Off on Anguil to Exhibit for the First Time at AISTech

Hosted by the Association for Iron and Steel Technology, AISTech 2025 is the largest annual iron and steel conference and exposition and the place where the steel industry comes together. Anguil team members will be on hand throughout the conference to speak with attendees about the pollution abatement technologies and techniques being applied on the various iron and steel applications.

Interested in setting up a meeting with one of our sales engineers to discuss how our innovative solutions can meet the needs of your application? Call Kevin Summ at 414-365-6400 or email us, and we will set aside some time to speak with you about your unique needs.

More information on the trade show and attendee registration can be found here. We hope to see you in Nashville!

Anguil Exhibiting Once Again at Environmental Trade Fair and Conference (ETFC)

Comments Off on Anguil Exhibiting Once Again at Environmental Trade Fair and Conference (ETFC)

Anguil has long been a pollution control equipment leader in the Natural Gas Production and Refining and Petrochemical industries. In fact, Anguil is the largest supplier of oxidizer technologies to the natural gas industry. Our solutions, including Regenerative Thermal Oxidizers (RTOs), Direct Fired Thermal Oxidizers (DFTOs), and Vapor Combustors, are engineered with careful consideration given to the design and material selection to avoid corrosion, equipment failures and non-compliance. Anguil oxidizers are built with quality materials of construction and engineered to withstand difficult streams and often remote installations. With additional expertise in Industrial Wastewater Treatment solutions as well as local representatives and service personnel, Anguil is positioned to be a single-source provider of air and water pollution control needs for the greater Texas region.

Held at the Henry B. Gonzalez Convention Center, Anguil engineering experts will be onsite in Booth #564 to discuss how our innovative solutions can meet the needs of your application. More information on the trade show and attendee registration can be found here.

We look forward to seeing you there!

Anguil Awarded Maturing Status by Green Masters Program

1,660 CommentsThe Wisconsin Sustainable Business Council has once again recognized Anguil Environmental Systems, Inc. for its sustainability efforts as part of its Green Masters Program.

Recognizing sustainable actions by businesses from across the state of Wisconsin, the Green Masters program works to identify companies that have taken actions within a variety of sustainability pillars. Participants receive recognition for their sustainability accomplishments and use the program to develop ideas to plan future sustainability actions.

For the tenth year in a row, Anguil has been recognized as a Wisconsin Green Masters Program Participant. In 2023, the Green Masters program updated its award categories, leading Anguil to be awarded Maturing status within our industry. The Green Masters Program provides a third-party, objective set of criteria for defining sustainability initiatives and legitimizes our work to push sustainability into our supply chain. Anguil is continually evaluated and accepted based on our involvement in key areas of environmental stewardship, community involvement and impact, employee experience, and sustainable governance.

While the corporate landscape continues to adapt and adjust post-pandemic, Anguil has continued to make strides in its sustainability efforts. A major project completed in 2024 included the removal of single-use plastics throughout the Anguil corporate headquarters in Milwaukee; reusable and/or sustainably-produced utensils, bowls, plates, cups, and mugs are stocked in each kitchen, and each employee received a set of reusable corn-based utensils. Additionally, Anguil’s employee-led sustainability team has implemented a switch from single-use batteries to rechargeable batteries throughout the corporate office.

On Anguil’s sustainability goals, the executive team believes, “It is important to us that every employee knows what we stand for, our values, and future goals. This takes some work, practice, repetition, and belief. In the end, it revolves around communication from every level of our organization. With this, we believe we can create a more sustainable company, saving time, money, and resources — which then opens the door for more opportunity and growth.”

The Green Masters Program is an objective, point-based recognition, assessment, and certification program that enables Wisconsin businesses from any size or sector to measure and improve their sustainability strategy. The program has four levels of participation: Adapting, Advancing, Maturing, and Green Master. Anguil has achieved Maturing status. Each year the top quartile of the program’s companies are recognized as Green Master companies at the annual WSBC Conference, held in November.

“The Green Masters Program is a tool for businesses to assess and grow their sustainability actions, to benchmark against others in their industry, and to receive a third party credential recognizing their sustainability achievements,” says WSBC’s managing director, Jessy Servi Ortiz.

To learn more about the program, visit wisconsinsustainability.com/greenmasters.

Industry Collaboration Helps Sterilizer Meet New Ethylene Oxide (EO) Regulation Ahead of Compliance Date

Comments Off on Industry Collaboration Helps Sterilizer Meet New Ethylene Oxide (EO) Regulation Ahead of Compliance DateUnder new regulations from the Environmental Protection Agency (EPA), sterilization companies that utilize Ethylene Oxide (EO) have until April 2026 to ensure pollution control technologies are in place to remove up to 99.99% of the emissions coming from aeration rooms, sterilization chamber exhausts, and back vents, or shut down production.

Meeting and measuring to these strict standards will be challenging. Many sterilizers are scrambling to purchase new combustion systems and monitoring devices to meet the deadline, but two industry experts are offering alternatives.

One such sterilizer in the United States engaged Anguil Environmental Systems and Montrose Environmental to see what could be done to retrofit an existing catalytic oxidizer with peak shaver that was originally designed for 99.9% removal or less than 1ppm per the previous regulations. Anguil, a pollution control system provider, and Montrose, a monitoring and testing supplier, met with the sterilizer to evaluate the system.

Using computational fluid dynamics (CFD) modeling to simulate flow and heat transfer within the induced draft system, engineers at Anguil recommended internal modifications be made within the oxidizer structure. Constructed of stainless steel, the internal modifications included multiple mixing vanes that provided sufficient blending to provide uniform flow and temperature distribution into the catalyst. Modifications were also made to the burner configuration to ensure better mixing, uniform temperature and flow distribution within the oxidizer.

During testing, Montrose simultaneously monitored the outlet of the peak shaver (catalytic oxidizer inlet) as well as the catalytic oxidizer outlet. Montrose utilized the Thermo Fisher Scientific™ Optically Enhanced MAX-IR™ OE-FTIR Gas Analyzer gas analyzer which allowed for measuring the outlet down to sub ppb levels while also measuring the inlet, where concentrations can be in the hundreds of ppm (without having to dilute the sample).

Through this industry collaboration, the sterilizer was able to meet and prove compliance with the new regulatory standards without purchasing a new abatement device or shutting down production.

Anguil Environmental’s Proven EO Abatement Equipment

Catalytic Oxidizers are one of the most widely accepted control technologies available to control VOC emissions from the EO sterilization processes. Combining our flagship catalytic oxidizer with a peak shaver, Anguil’s EO abatement systems have helped clients achieve 99.99% destruction efficiency and limited EO concentrations to under one part-per-million by volume.

Anguil systems ensure zero leakage of EO from the oxidizer and safe operation by integrating the peak shaver, a packed tower counter-flow water scrubber, that absorbs ethylene oxide gas into the water by ensuring a high contact area between the gas and the water, preventing unsafe, high concentration conditions.

- Removal efficiencies of 99.99% to meet requirements in the US EPA NESHAP or as low as 0.5 mg/Nm³ to satisfy European regulations.

- Custom oxidation technologies to accommodate space restraints and site-specific requirements.

- The necessary experience to modify existing abatement systems to meet the new regulations.

- Local manufacturing and service capabilities throughout North and South America, Europe, and Asia for short equipment lead times and service response.

- Integrated Peak Shavers/Balancers with specialty mixers and detonation arrestors to ensure safe and effective operation.

- Natural gas, electric, propane, steam, or hydrogen heated oxidizers for carbon reduction initiatives.

- Over 25 years with EO abatement experience!

Montrose Environmental’s Proven Measurement Design

Montrose Environmental Group and Thermo Fisher Scientific have collaborated to provide an all-encompassing solution for organizations facing challenges in EO emissions monitoring, testing, and regulatory compliance. By integrating Montrose’s extensive project services expertise with Thermo Fisher’s cutting-edge Optically Enhanced MAX-IR™ OE-FTIR Gas Analyzer, clients gain access to a powerful combination that streamlines their efforts to meet stringent regulations.

The EMS-10™ Continuous Emissions Monitoring System (CEMS) is a fully automated 4-channel stack emission monitoring system which integrates the Thermo Fisher OE-FTIR analyzer. The EMS-10 system can quantify ethylene oxide down to a detection limit of under 1 ppb while maintaining short cycle times. The EMS-10 was designed to meet all the requirements found in PS-19 and operates as a continuous monitor with little-to-no user interaction.

For more information on the Montrose monitoring technology, visit this page.

Ten Years of Top Workplace Awards for Anguil!

Comments Off on Ten Years of Top Workplace Awards for Anguil!

“This is our tenth time being honored as a Top Workplace and the recognition has not lost its significance with management,” said Deb Anguil, Chief Operating Officer of Anguil Environmental. “Family culture is so important at Anguil. The fact that Top Workplace winners are determined by feedback from employees tells us that our team members feel a part of the family, which is very important to organizational growth.”

“Anguil is committed to protecting the environment with unmatched engineering, innovative equipment, guaranteed compliance, and reliable service,” said Chris Anguil, President of Anguil Environmental. “None of that is possible without the dedication and hard work of our employees. Thanks to everyone for making Anguil a Top Workplace. We appreciate everything you do and especially your tenacity and efforts during these tough times.”

The complete list of winners can be found on Jsonline.com.

See what it is like to be an Anguil Employee.

Anguil Industrial Acquires Young & Bertke Air Systems Company

Comments Off on Anguil Industrial Acquires Young & Bertke Air Systems CompanyAcquisition of Young & Bertke Air Systems Company Creates Common Ownership with Anguil Environmental Systems, Inc. to Strengthen Industry Presence

Milwaukee, Wisconsin – April 16, 2024 – Chris Anguil, President and Deborah Anguil, Chief Operating Officer of Anguil Environmental Systems Inc. (Anguil), a globally recognized leader in industrial pollution control technologies and services, proudly announce the formation of Anguil Industrial, LLC, to complete the acquisition of Young & Bertke Air Systems Company, a distinguished mechanical contractor in Cincinnati, Ohio. The strategic acquisition, effective immediately, enhances the offerings of each company, both with decades of expertise and experience in environmental systems and mechanical contracting services.

For Anguil, the move underscores its unwavering dedication to innovation and growth within the environmental sector. “This acquisition reinforces our commitment to providing quality environmental systems and services amid our remarkable growth,” stated Chris Anguil, President of Anguil.

Notably, Anguil and Young & Bertke have a longstanding history of collaboration, having partnered on countless projects over the past 25 years. With common ownership now in place, both entities are poised to enhance those operational synergies while preserving the integrity of their respected brand names.

About Anguil Environmental:

Headquartered in Milwaukee, Anguil is a leading provider of air pollution control systems, wastewater treatment technologies, and energy recovery equipment for industrial applications and manufacturing industries. They have fabrication, installation, services and sales operations in the United Kingdom, India, China, and Taiwan. Since 1978, Anguil has been protecting the environment through unmatched engineering, innovative equipment, guaranteed compliance, and reliable service.

About Young & Bertke, An Anguil Industrial Company:

Since its founding in 1920, Young & Bertke has built a reputation for quality fabrication and installation of mechanical systems related to air ventilation and purification. This includes, but is not limited to, ductwork, dust collectors, tanks, platforms, enclosures, dampers, and specialty sheet metal fabrication. Their highly skilled technicians take pride in doing the job right the first time and every time.

Media Information:

Anguil Environmental Systems, Inc. / www.anguil.com / (800) 488-0230

Young & Bertke, An Anguil Industrial Company / www.youngbertke.com / (513) 241-5566

The Changing Workforce and Its Impact on Your Wastewater Treatment System

1,396 CommentsWe have all heard about the “Great Resignation” in the news and the significant numbers of people retiring or leaving the work force.

A Washington Post article, [i] stated that 4.3 million people of all ages left the workforce in August of 2021 alone – that’s almost 3% of the total workforce gone in one month. Per Axios, [ii] 3 million baby boomers retired early because of COVID pandemic. It is important to know the numbers and reasons why people are leaving the workforce, but it is even more critical to know how you are going to protect your organization when one of your workers retires or leaves for another job.

Most companies have contingency plans to replace C-level and senior executives when they abruptly leave. However, not as many organizations have replacement plans in place when the people operating equipment suddenly quit. For decades, your wastewater treatment systems have been completely out of mind, not causing any crisis or concern. Wastewater has been continually treated, solids removed off site, chemicals delivered and consumed, and all the while your wastewater has been (generally) in compliance with discharge standards. In the background, the same personnel have been quietly keeping the legacy system operating.

Because the system has been operating in the background of your more visible revenue-generating objectives such as producing products, many things have been neglected. It is likely that that many of the monitors, meters, instruments, and automation (if they even existed) have failed, and the overall condition of your wastewater treatment system has deteriorated. Someone was probably told about it, and it was likely deemed there were no funds to fix it at the time. Maybe the original wastewater it was designed to treat has changed because your production process has changed, and the system has been retrofitted several times. So, your operator had done what every wastewater treatment operator does: they find a manual work around and improvised solutions.

This is not everyone’s situation, but it is the story of so many plants. Systems installed decades to half-centuries ago are not only in jeopardy of completely failing, but the men and women who have kept them running are largely part of the groups retiring early or quitting for a better job.

Let’s hope you do not lose your system operator. However, if you realistically think your system and workforce could be suffering from similar ailments described here, we have some cost-effective recommendations you can implement now to ensure workforce changes do not negatively impact your operation or bottom line.

System Audit

Have a firm focused on water treatment applications come in to review your system. Having a firm focused on water treatment applications evaluate your current system is a quick way to assess your situation. Ideally, they can identify critical aspects of the system that require immediate attention and those which can be addressed later. They should be able to evaluate the system as a whole to determine if it is cost effectively meeting your current – and future needs while also providing you with replacement options.

Controls and Advanced Automation Upgrade

Typically, upgrading system controls and automation provides return on investment and quickly limits exposure from workforce challenges. Replacement of broken instrumentation, installation of additional monitoring, and a new control panel with PLC controls can automate the treatment process, reducing the workload for your staff while ensuring the system is operating properly. Notifications can alert employees to system upset conditions and provide maintenance reminders for things like filter changes, chemical replenishment, or solids removal.

Chemical Optimization

Many companies have not changed the makeup of their water treatment chemicals since the system was first installed. Over that time, your costs probably continued to rise, but you may have no idea if you are in line with market prices. Additionally, are you sure a more cost-effective chemical treatment protocol isn’t available? Has your wastewater changed from the original production line you ran? A short lab trial by a third-party can provide testing validation across multiple chemicals and provide a complete OPEX assessment for your consideration. Chemical costs truly add up, especially when many do not periodically evaluate the options.

Sludge Handling Automation

Additional flow or changes to the wastewater generating processes can impact the performance of your sludge handling equipment. Additional solids could mean your operator has to increase the number of times the filter press is dumped, pulling the operator from more critical tasks. Additional oil or solvents in the solids could negatively impact the performance of the filter press, increase the disposal weight of your solids, or possibly cause the solids to not be accepted at a normal landfill. As human resources become more scarce, automated sludge handling systems can offer a cost-effective solution to many of those problems.

Equipment Replacement v. System Replacement

Site audits are often performed when someone believes a new wastewater treatment system is required. This could be due to expansion, age/condition of current system, poor performance, or all the aforementioned conditions combined. A good site audit would include the determination of what equipment can be reused and which cannot. Additionally, lab and field testing can validate where a system may be failing. In many cases, companies can identify a single piece of equipment for replacement instead of scrapping the entire treatment train. Be sure to communicate with your provider so that you can have all the supporting data for all the options available to you.

Proper Documentation

Part of properly maintaining any pollution control device hinges on document control. The changing employment situation is magnifying the importance of keeping critical documents not only accessible but also updated. Documenting operating procedure can be the difference between compliance and non-compliance when a key person abruptly leaves an organization. Companies should take every step to maintain updated documents such as the Process and Instrumentation Diagram (P&ID), electrical schematics, sequence of operation, set points, and alarm conditions. Don’t find yourself searching for the company’s permit operating conditions when they should be stored in a centralized location with other critical documentation.

In conclusion, the GREAT RESIGNATION has significantly changed the work landscape and likely will continue to do so. One simple way to ensure you stay in compliance with standards, continue to be a good neighbor to your community, and stay cost-effective in production of your goods is to ensure your wastewater system and process is prepared for operator disruption.

At Anguil, our team of industrial wastewater treatment experts can help you optimize your wastewater system and process. To find out more, contact us today.

Want to learn more?

Listen to our team of experts in this podcast with EHS Daily Advisor.

[i] Washington Post. A record number of workers are quitting their jobs, empowered by new leverage. Oct. 12, 2021. Eli Rosenberg, Abha Bhattarai, and Andrew Van Dam

[ii] Axios. Millions of baby boomers retired early during the pandemic. Oct. 29, 2021. Erica Pandey, author of What’s Next

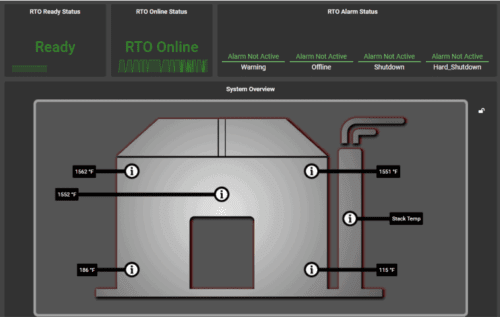

Anguil Announces Industrial Internet of Things (IIoT) Platform, Seeks Pilot Customers

1,275 CommentsAnguil has announced the launch of their Industrial Internet of Things (IIoT) software platform and is now seeking participants for their pilot program. Unlike the Internet of Things (IoT), which largely centers on consumer devices, IIoT focuses on bringing connectivity and data exchange capabilities via an internet connection to industrial and manufacturing contexts.

Anguil’s IIoT software platform is tailored specifically for enhancing operational transparency and reporting capabilities for environmental pollution control

According to Richard Oakes, Client Manager and IIoT Business Development Manager, the timing couldn’t be better for Anguil’s IIoT solution: “IoT has disrupted and transformed widespread consumer markets. Why should the environmental pollution control industry be any different? The industry has been mature for a long time – the next logical step is advanced automation and controls. Until now, there really hasn’t been much out there for environmental managers looking to modernize their environmental equipment management strategy. Our IIoT platform is a game changer for them.”

To further test and enhance their IIoT platform, Anguil is seeking industrial facilities with existing environmental technologies to participate in a pilot program. Participants partner with Anguil to integrate the IIoT platform with their environmental equipment for a six-month period, providing feedback on the existing interface and input on desired functionality. To qualify as a pilot participant, Anguil is seeking facilities willing to provide Anguil’s IIoT team technical access to their system control panel. Besides minimal set-up costs, there is no cost to participate as a pilot customer and no long-term obligation. At the end of the pilot program, participants will be offered the option to continue IIoT services or to end the engagement with no pressure to purchase.

For more information on Anguil’s IIoT capabilities and to apply to the IIoT Pilot Program, go to https://anguil.com/engineering-services/industrial-internet-of-things-iiot.