The Changing Workforce and Its Impact on Your Wastewater Treatment System

1,395 CommentsWe have all heard about the “Great Resignation” in the news and the significant numbers of people retiring or leaving the work force.

A Washington Post article, [i] stated that 4.3 million people of all ages left the workforce in August of 2021 alone – that’s almost 3% of the total workforce gone in one month. Per Axios, [ii] 3 million baby boomers retired early because of COVID pandemic. It is important to know the numbers and reasons why people are leaving the workforce, but it is even more critical to know how you are going to protect your organization when one of your workers retires or leaves for another job.

Most companies have contingency plans to replace C-level and senior executives when they abruptly leave. However, not as many organizations have replacement plans in place when the people operating equipment suddenly quit. For decades, your wastewater treatment systems have been completely out of mind, not causing any crisis or concern. Wastewater has been continually treated, solids removed off site, chemicals delivered and consumed, and all the while your wastewater has been (generally) in compliance with discharge standards. In the background, the same personnel have been quietly keeping the legacy system operating.

Because the system has been operating in the background of your more visible revenue-generating objectives such as producing products, many things have been neglected. It is likely that that many of the monitors, meters, instruments, and automation (if they even existed) have failed, and the overall condition of your wastewater treatment system has deteriorated. Someone was probably told about it, and it was likely deemed there were no funds to fix it at the time. Maybe the original wastewater it was designed to treat has changed because your production process has changed, and the system has been retrofitted several times. So, your operator had done what every wastewater treatment operator does: they find a manual work around and improvised solutions.

This is not everyone’s situation, but it is the story of so many plants. Systems installed decades to half-centuries ago are not only in jeopardy of completely failing, but the men and women who have kept them running are largely part of the groups retiring early or quitting for a better job.

Let’s hope you do not lose your system operator. However, if you realistically think your system and workforce could be suffering from similar ailments described here, we have some cost-effective recommendations you can implement now to ensure workforce changes do not negatively impact your operation or bottom line.

System Audit

Have a firm focused on water treatment applications come in to review your system. Having a firm focused on water treatment applications evaluate your current system is a quick way to assess your situation. Ideally, they can identify critical aspects of the system that require immediate attention and those which can be addressed later. They should be able to evaluate the system as a whole to determine if it is cost effectively meeting your current – and future needs while also providing you with replacement options.

Controls and Advanced Automation Upgrade

Typically, upgrading system controls and automation provides return on investment and quickly limits exposure from workforce challenges. Replacement of broken instrumentation, installation of additional monitoring, and a new control panel with PLC controls can automate the treatment process, reducing the workload for your staff while ensuring the system is operating properly. Notifications can alert employees to system upset conditions and provide maintenance reminders for things like filter changes, chemical replenishment, or solids removal.

Chemical Optimization

Many companies have not changed the makeup of their water treatment chemicals since the system was first installed. Over that time, your costs probably continued to rise, but you may have no idea if you are in line with market prices. Additionally, are you sure a more cost-effective chemical treatment protocol isn’t available? Has your wastewater changed from the original production line you ran? A short lab trial by a third-party can provide testing validation across multiple chemicals and provide a complete OPEX assessment for your consideration. Chemical costs truly add up, especially when many do not periodically evaluate the options.

Sludge Handling Automation

Additional flow or changes to the wastewater generating processes can impact the performance of your sludge handling equipment. Additional solids could mean your operator has to increase the number of times the filter press is dumped, pulling the operator from more critical tasks. Additional oil or solvents in the solids could negatively impact the performance of the filter press, increase the disposal weight of your solids, or possibly cause the solids to not be accepted at a normal landfill. As human resources become more scarce, automated sludge handling systems can offer a cost-effective solution to many of those problems.

Equipment Replacement v. System Replacement

Site audits are often performed when someone believes a new wastewater treatment system is required. This could be due to expansion, age/condition of current system, poor performance, or all the aforementioned conditions combined. A good site audit would include the determination of what equipment can be reused and which cannot. Additionally, lab and field testing can validate where a system may be failing. In many cases, companies can identify a single piece of equipment for replacement instead of scrapping the entire treatment train. Be sure to communicate with your provider so that you can have all the supporting data for all the options available to you.

Proper Documentation

Part of properly maintaining any pollution control device hinges on document control. The changing employment situation is magnifying the importance of keeping critical documents not only accessible but also updated. Documenting operating procedure can be the difference between compliance and non-compliance when a key person abruptly leaves an organization. Companies should take every step to maintain updated documents such as the Process and Instrumentation Diagram (P&ID), electrical schematics, sequence of operation, set points, and alarm conditions. Don’t find yourself searching for the company’s permit operating conditions when they should be stored in a centralized location with other critical documentation.

In conclusion, the GREAT RESIGNATION has significantly changed the work landscape and likely will continue to do so. One simple way to ensure you stay in compliance with standards, continue to be a good neighbor to your community, and stay cost-effective in production of your goods is to ensure your wastewater system and process is prepared for operator disruption.

At Anguil, our team of industrial wastewater treatment experts can help you optimize your wastewater system and process. To find out more, contact us today.

Want to learn more?

Listen to our team of experts in this podcast with EHS Daily Advisor.

[i] Washington Post. A record number of workers are quitting their jobs, empowered by new leverage. Oct. 12, 2021. Eli Rosenberg, Abha Bhattarai, and Andrew Van Dam

[ii] Axios. Millions of baby boomers retired early during the pandemic. Oct. 29, 2021. Erica Pandey, author of What’s Next

Anguil Announces Industrial Internet of Things (IIoT) Platform, Seeks Pilot Customers

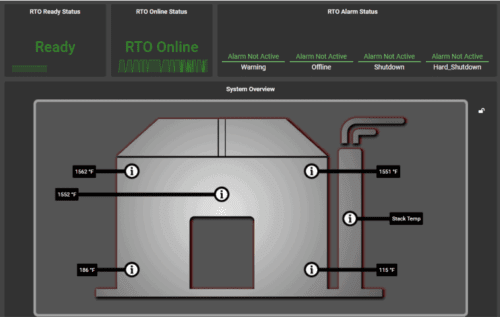

1,275 CommentsAnguil has announced the launch of their Industrial Internet of Things (IIoT) software platform and is now seeking participants for their pilot program. Unlike the Internet of Things (IoT), which largely centers on consumer devices, IIoT focuses on bringing connectivity and data exchange capabilities via an internet connection to industrial and manufacturing contexts.

Anguil’s IIoT software platform is tailored specifically for enhancing operational transparency and reporting capabilities for environmental pollution control

According to Richard Oakes, Client Manager and IIoT Business Development Manager, the timing couldn’t be better for Anguil’s IIoT solution: “IoT has disrupted and transformed widespread consumer markets. Why should the environmental pollution control industry be any different? The industry has been mature for a long time – the next logical step is advanced automation and controls. Until now, there really hasn’t been much out there for environmental managers looking to modernize their environmental equipment management strategy. Our IIoT platform is a game changer for them.”

To further test and enhance their IIoT platform, Anguil is seeking industrial facilities with existing environmental technologies to participate in a pilot program. Participants partner with Anguil to integrate the IIoT platform with their environmental equipment for a six-month period, providing feedback on the existing interface and input on desired functionality. To qualify as a pilot participant, Anguil is seeking facilities willing to provide Anguil’s IIoT team technical access to their system control panel. Besides minimal set-up costs, there is no cost to participate as a pilot customer and no long-term obligation. At the end of the pilot program, participants will be offered the option to continue IIoT services or to end the engagement with no pressure to purchase.

For more information on Anguil’s IIoT capabilities and to apply to the IIoT Pilot Program, go to https://anguil.com/engineering-services/industrial-internet-of-things-iiot.

Meeting Pollution Control Compliance Through System Design & Engineering

554 CommentsAnguil’s pollution control technologies have been used for cleaner air, water, and energy in a wide range of manufacturing applications across almost every industry. The need to comply with pollution control regulations goes beyond ESG (Environmental, Social and Corporate Governance), as non-compliance with pollution control regulations can be extremely costly for businesses from many aspects.

The use of the proper pollution control technologies can lead to smaller overall production costs through energy-efficient design and reliable construction practices. Solutions from Anguil can lead to a dramatic reduction in costs as well as seamless integration through our expertise in system design and engineering.

Your Business, Your Process

Our designs combine widely used products with innovative, custom-engineered solutions. We aim to work closely with you to tailor our systems to your unique business needs. Ultimately, this means our systems can help you reduce overall costs, minimize non-compliance issues, and decrease your environmental footprint.

We employ a team of skilled engineers from a wide cross-section of disciplines, including mechanical, structural, environmental, and electrical engineering. This diversity allows us to deliver a tailored service whereby we can address a wide range of process needs.

Reliability of Design

It is extremely important to clients that our pollution control technology system designs are at the highest standard, and operational in a timely fashion. Throughout our system design, we use a gate process that allows us to ensure that each stage meets full quality control requirements before proceeding.

This allows us to ensure that our system design and engineering leads to maximum customer satisfaction from engineering through to commissioning. Our quality assurance team consistently monitors our processes to ensure we are meeting our core values of continuous improvement and enhanced customer experience.

Examples of Anguil’s System Design and Engineering in Practice

In recent times, the Chinese government has been increasing the restrictive nature of environmental protection regulations. In Shanxi Province, China, a mining company wanted to adopt a new technology to convert ventilation air methane (VAM) into usable energy. Anguil’s system design and engineering expertise was used to recommend the Regenerative Thermal Oxidizer (RTO) technology which destroys emissions while using waste heat to generate energy. Anguil’s system design and engineering of the RTO also means that no auxiliary energy is necessary for combustion as long as minimal methane concentrations are maintained.

Anguil’s expertise in system design and engineering allowed us to work with a coil coating facility to generate steam and savings using waste heat. The facility wanted to minimize their exhaust air temperature and operating costs using an RTO.

The customer was able to utilize a large airflow and high exhaust temperature to create energy recovery measures and optimize processes while minimizing operating expenses. As the process needs a lot of steam this would provide a much-needed resource via energy recovery. Anguil installed an air-to-steam waste heat recovery boiler to recover exhaust waste heat from the natural gas-fired thermal oxidizer and created 25 psig of steam. This system design and engineering expertise led to the facility saving $216,770 per year, paying for itself within six months.

At Anguil we are always looking for ways to enhance our system design and engineering processes to ensure that we attain exceptional customer satisfaction. To find out more, contact us today.

Pollution Control Technologies—Driving Uptime, Meeting Compliance & Reducing Operating Costs

1 CommentAir and water pollution can have a significant detrimental impact on both human health and the environment. Non-compliance with pollution control regulations can be both time-consuming and expensive. Your company could be given increasingly large financial penalties for not meeting regulation standards, resulting in higher overall costs for your company.

Soil Remediation at Superfund Sites across the USA

1,269 CommentsSevere soil contamination is a major cause for concern that can have a harmful impact on human health. The U.S. Environmental Protection Agency (EPA) regulates the levels of pollution in soils to protect the environment and reduce the likelihood that people will come into contact with harmful contaminants. Sites that are severely polluted can be remediated using a choice of pollution control technologies, and the EPA rigorously enforces the need for soil remediation as part of the Superfund program.

How to Select the Right Pollution Control Technologies

1,295 CommentsAir pollution can cause both long- and short-

The Power of Many – Expanding Possibilities of Remote Connection

Leave a CommentEstablishing a Remote Connection to your oxidizer is one of the most critical service enhancements you can make.

Manufacturers understand that establishing a remote connection with pollution control systems and process equipment is essential for business continuity. For Anguil clients with remote connection capability, it is both a lifeline during system upsets as well as a “force-multiplier,” akin to getting the experience and knowledge of several engineers on site for the price of one.

How is Remote Connection Typically Used?

Anguil generally uses remote assistance in our Field Service and Engineering departments to connect with equipment controls and make program changes or

We can accomplish even more equipment troubleshooting if the customer has an employee we can direct on what to physically check. In these cases, we can solve problems very fast, saving a potentially costly service visit or solving an equipment emergency when time cannot wait for the arrival of our service personnel.

Remote Connection in Uncertain Times

While remote connection has been a standard inclusion with Anguil equipment for many years, it gained elevated significance during global pandemic uncertainty when travel and many businesses were shut down. While Anguil remained open as an essential business, remote connection enabled us to stay connected to our customers and even support them in new ways, including “site” supervision.

For almost every aftermarket project requiring equipment work, Anguil sends a Field Service Engineer (FSE) to site for project supervision. However, during the COVID-19 global pandemic, Anguil was unable to go to a customer’s site due to COVID-19 safety restrictions at the plant. The project was a complex internal heat exchanger replacement, which required the removal of a large portion of ductwork attached to the system, electrical, and structural steel. This undertaking normally would have required an FSE onsite for up to a month.

The pandemic restrictions certainly presented a challenge to our aftermarket team, but at Anguil, we do whatever it takes to deliver for our customers.

Remote Connection Saves the Day in a New Way

Fortunately, the customer had remote connection established with Anguil. Our Aftermarket team decided to leverage this capability in a new way: remote installation supervision. With the customer onboard, our team strategized on the best execution strategy. A technical and mechanical package was put together

for the contractor to follow and conversations during the installation were on an as required basis. Most importantly, the remote installation approach offered additional flexibility with staffing: instead of assigning an FSE for project supervision, the Aftermarket team assigned the Project Engineer.

There were multiple benefits to this approach as the Project Engineer has much more intimate knowledge on the work being done. He completed many Solidworks models and drawings to guide the customer on how to remove and replace the heat exchanger. The Anguil Engineer was also able to monitor their

progress remotely at various points with a check in video call and resolve technical issues with the customer at their pace. At the same time, sending the Project Engineer to site to supervise would not be ideal for Anguil or our other Aftermarket customers as he could not keep up on his other projects while on site.

Remote installation supervision also softened the blow of other project complications. The customer faced many personnel and weather issues during installation. COVID-19 shut the plant down in the middle of the project for two weeks. A snowstorm shut the plant down for a couple days. If Anguil had an FSE onsite during this time, they would have been stuck in a hotel for that amount of time.

Across the board, leveraging remote connection was a win-win for everyone. Due to the nature of this project and the savings incurred during remote assistance, Anguil was able to issue a credit to the customer worth over $12,000! The heat exchanger installation was successful and the customer was very pleased.

Interested in Remote Connection for Your Oxidizer System?

Remote connection capability is not just for Anguil systems! With a simple evaluation, Anguil can determine what needs to be done to get your oxidizer connected to our team of experts. Once online access is established, we can troubleshoot existing issues and help prevent future malfunctions. Get in Touch with Anguil’s Aftermarket team to learn more about adding remote connection capabilities.

How Do Regenerative Thermal Oxidizers Work

3,539 CommentsEffective air pollution control is important in modern industrial facilities where the goals of ensuring regulatory compliance, minimizing environmental impacts, and maintaining a healthy bottom line, are all closely interlinked.

Staying Ahead of Evolving EtO Regulations

9,841 Comments EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

Are you ready for the increased compliance challenges?

Why is everyone talking about ethylene oxide (EtO)? According to recent scientific studies, EtO is a more dangerous carcinogen than previously thought. Results from the latest National Air Toxics Assessment (NATA) have made EtO an increased focus of concern for the EPA and state regulators. For sterilization companies, this understandably makes you concerned about the safety of your employees and community, as well as your reputation.

In many cases, the traditional abatement technologies such as wet scrubbers and dry sorbents cannot meet the new EtO destruction requirements.

How does your abatement strategy measure up? How do you ensure that your abatement technology is up-to-date and meeting compliance requirements? With so much to lose, why take the risk with an unproven supplier?

A Proven EtO Abatement Equipment Design

Catalytic Oxidizers are one of the most widely accepted control technologies available to control VOC emissions from the EtO sterilization processes.

Anguil systems ensure zero leakage of EtO from the oxidizer and safe operation by integrating the peak shaver, a packed tower counter-flow water scrubber that absorbs ethylene oxide gas into the water by ensuring a high contact area between the gas and the water, preventing unsafe, high concentration conditions.

Sterilizers cannot afford to take the risk on an unproven company. We are proud of our reputation in the industry and our solutions that help ensure safer communities and sterilization operations. Learn more about our sterilization solutions here.

ANGUIL SYSTEM DESIGN FEATURES

- FLEXIBILITY: Base Metal Catalyst offers a large operational temperature window for flow and concentration variations

- COMPLIANCE: Horizontal Catalyst Tray Configuration avoids catalyst bed bypassing per NESHAP requirements

- PERFORMANCE: Leak-and-Dye Tested Shell & Tube Heat Exchanger guarantees 0% leakage of VOC-laden air into clean airstream, reduces operational costs

- SAFETY: Induced Draft Fan functions as a failsafe to prevent leakage into work environment

- DURABILITY: 304L SS Construction With Outer Aluminized Steel Frame increases equipment life, provides low-cost maintenance

- EASE OF USE: PLC With Human Machine Interface and Remote Connectivity System troubleshooting, alerts operator of equipment shutdowns

- ON SCHEDULE: Pre-Assembled, Wired, and Tested Prior to Shipment, can be installed within tight time restrictions due to high production levels

- EVEN, SAFE VOC LOADINGS: Integrated Peak Shaver evens out fluctuations in contaminant levels to a steady state, preventing unsafe, high concentration conditions

Anguil Announces Multi-million Dollar Order for EtO Sterilization Plant

Starting 2021 strong, Anguil announced a multi-million-dollar order for a 15,000 SCFM Catalytic Oxidizer with a Peak Shaver for a new ethylene oxide (EtO) sterilization plant. Anguil’s diversity of experience and wide breadth of technology offerings make us the popular industry choice for the nuanced and varied needs of the pharmaceutical industry where compliance is critical.

Learn more about our solutions for the pharmaceutical industry.

Have an Existing EtO Abator?

If you already have a pollution abatement system on your EtO process, Anguil’s suite of Aftermarket Services can ensure your equipment is optimized for

General Services

- 24/7 Emergency Service

- Routine or Troubleshooting Visit

- Operator Training

- Wastewater Treatment System Maintenance

Retrofits & Upgrades

- Increased Air or Water Flow Capacity

- Improved Destruction Efficiency

- Controls Enhancements

Preventive Maintenance

- Preventive Maintenance Evaluations

- Maintenance Contracts

- Predicative Maintenance Monitoring

Spare Parts

- Individual Spare Parts

- Recommended Spare Parts Packages

- Catalyst & Media

Explore Anguil’s Aftermarket Solutions.

Anguil’s engineers will diligently analyze your challenges and requirements to recommend a comprehensive, turn-key compliance solution. Our suite of quality engineered, air pollution control technologies will efficiently solve your pollution control challenges no matter the complexity. Contact Us to get started with your application.

4 Qualities to Look for in Your Next Environmental Partner

Leave a CommentNot all environmental technology providers are created equal. How do you ensure you make the smartest choice in such a significant relationship? Start by assessing these four qualities and asking the following questions to any potential environmental technology partner.

1. Engineering Experience and Expertise

Questions to Ask:

- What is the depth of your engineers’ experience?

- How many successful installations do you have in my industry?

- Who will my project manager be, and can I meet them?

2. Quality Design and Manufacturing for System Reliability

Your selected environmental technology partner should have a proven process in place for design and manufacturing processes to ensure

Questions to Ask:

- How is your fabrication process managed?

- What kind of Quality Assurance program is in place?

- What technology is leveraged during system design?

3. Integrated System Controls

When evaluating a potential partner, assess their in-house controls engineering capabilities and success record with integrating multiple equipment packages and process lines. Controls designs should be remotely accessible, resilient to downtime, account for safety and

Questions to Ask:

- How do your controls ensure safe, efficient, and reliable operation?

- What is your experience integrating abatement equipment and process lines?

- What remote connection capabilities are in place?

4. Robust Aftermarket Services Department for All Makes, Models & Manufacturers

A reputable partner should have an accessible aftermarket and service department to maximize system value through preventive and

Questions to Ask:

- Do you have a dedicated Aftermarket department?

- Do you offer 24/7 service support?

- Who will be servicing my equipment? Where are they based?

Anguil’s legacy of broad Industry Experience means our engineering experts are not pigeon-holed to a limited product portfolio to solve every application. Learn more about our System Design & Engineering capabilities and Contact Us to get started on a custom solutions specific to your application.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.