Formaldehyde Production

Comments Off on Formaldehyde Production The Challenge

The Challenge

A major chemical manufacturer required a pollution control system with minimal operational cost to destroy the Hazardous Air Pollutant (HAP) by-products of a formaldehyde production process. A key issue was system reliability; the plant operates 24 hours a day and only shuts down once per year for plant-wide preventive maintenance.

The Solution

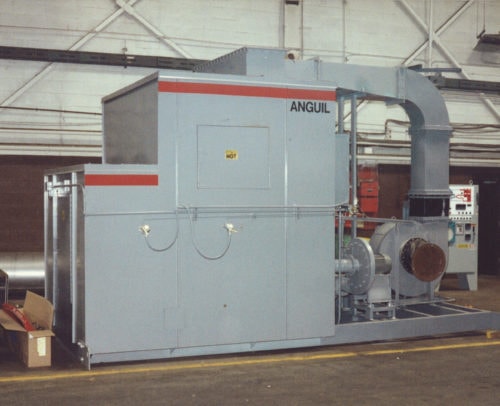

After thorough technical evaluation, the company selected Anguil Environmental Systems, Inc. to solve their HAPs emission problem and put them in compliance. Anguil installed a catalytic oxidation system that meets all applicable regulatory requirements. The system uses a 65% effective shell and tube heat exchanger that allows self-sufficient operation under normal process loadings.

In the formaldehyde production process, methanol reacts with air in the presence of catalyst to produce formaldehyde. Process yields are normally quite high, with over 95% to 98% of methanol ending up as formaldehyde. Some ancillary compounds are generated in the oxidation process due to catalyst inefficiencies. The emission by-products that require control are carbon monoxide, dimethyl ether, methanol and formaldehyde. Both formaldehyde and methanol are classified as Hazardous Air Pollutants (HAPs) and require stringent emission reduction.

Anguil’s extensive experience with formaldehyde manufacturers helped the company in examining possible pollution control solutions. On this application conditions were favorable to use a catalyst for VOC control. Since the customer uses catalyst in their process, they were comfortable using catalyst for VOC and CO oxidation. In addition, there is a relatively high CO and VOC concentration exhausted from the process which would allow the catalytic oxidizer to function without any auxiliary energy requirement.

A precious metal catalyst was selected as the core of the catalytic system due to its ability to provide 99+% DRE of the formaldehyde, methanol, dimethyl ether, and carbon monoxide at a catalyst bed inlet temperature as low as 525° F (275° C). The catalyst is deposited on a monolithic, honeycomb, stainless steel substrate. The catalyst design minimizes the pressure drop through the oxidizer.

Another cost-effective design feature was the integral 65% effective shell and tube heat exchanger that was selected to preheat the incoming process stream prior to the catalyst bed. The exhaust air from the catalyst outlet is hot sufficient to keep the oxidizer operating at temperature with no auxiliary energy requirements.

Oxidizer warm-up following a plant shut-down was also a crucial design consideration. Neither natural gas nor propane is readily available at many of the company’s formaldehyde plants. For this reason an electric heating system was selected to bring the oxidizer up to the 525° F operational temperature prior to the processing of the plant off-gases. A small pre-heat fan and an electric heater were designed to bring the system up to initial operating conditions. Once at setpoint temperature, the oxidizer process inlet valve is incrementally opened to allow the process exhaust gases. As sufficient CO/HAP/VOC loading enters the oxidizer releasing heat from the exothermic reaction, the electric preheat elements shut off completely. No additional energy is added to the system. In fact, the oxidizer doesn’t even use fan energy since it takes advantage of the process pressure to push through the oxidizer.

The Result

The system is operating and providing well over the 99+% destruction efficiency required. The success of this system resulted in this chemical company purchasing another 25 and counting additional Anguil systems for formaldehyde plants around the world. Anguil’s experience, innovative design and quality manufacturing resulted in another satisfied Anguil customer and a long-term partner with air pollution control.

Cumene Plant

Comments Off on Cumene PlantThe Challenge

An East coast chemical plant that manufactures phenol, acetone and alphametyl styrene from cumene planned to install an air pollution control system to control the Volatile Organic Compounds (VOCs) emitted during their chemical production process. Phenol is consumed internally as an intermediate chemical while the acetone and alphametyl styrene are sold off. Once the chemicals are produced, they are shipped to another plant to make carpet fibers. This plant already had a carbon recovery system in place, but needed a system to control the low concentration residual process stream from the carbon recovery system.

The Solution

The Solution

After thorough vendor evaluation, the plant selected and contracted Anguil Environmental Systems to solve their emission problem. The combination of VOCs in the stream and their low concentration made catalytic oxidation the ideal technical choice. Plant engineers had concerns that an oxidation system might have an adverse effect on the precise pressure and volume control required in their production process. Anguil’s experience and success with chemical process applications provided the plant personnel with the confidence that catalytic oxidation was a viable solution.

The Result

An Anguil Model 400 forced draft catalytic oxidizer, rated for 65,000 SCFM (102,512 Nm3/Hr) was selected to process the flow from twenty-five sources of production emissions. As always, Anguil’s engineering staff worked closely with the customer throughout the design and manufacturing processes to ensure that the system precisely met their requirements. The system was sized to provide 99% destruction removal efficiency and 70% thermal energy recovery. The reactor section contains a catalyst bed to oxidize the incoming airflow. The catalyst converts VOCs into carbon dioxide, water vapor and thermal energy.

In order to address the concern of the precise pressure and volume control required for the customer’s production process, Anguil manufactured a four-module, fully welded shell and tube heat exchanger. By using a greater plate thickness, as well as fabricating “ribs” and “dimples” on the plates, a pressure differential of 87.5 w.c. was sustained.

The plant’s process operates 24 hours a day, seven days a week. The oxidation unit is required to run continuously, with 100% up-time to accommodate the aggressive chemical production process.

The Programmable Logic Control (PLC) system was integrated into the customer’s control system and redundancy was designed into the most critical items. A difficult pollution control issue was solved by Anguil, resulting in another satisfied customer.

Engine Test Cell Exhaust: RTO

Comments Off on Engine Test Cell Exhaust: RTOThe Challenge

A Midwestern outboard engine manufacturer bought a three-year-old plant to produce its marine engines. When finished, the engines are removed from the assembly line and run for quality control. The 25,000 SCFM (40,125 Nm3/hr) of exhaust from testing contains volatile organic compounds (VOCs) that require regulatory compliance. Also within this exhaust is a great deal of water vapor and carbon monoxide (CO).

Anguil had already planned to equip this plant with pollution control equipment for its paint processing operation using a new Anguil Emissions Concentrator coupled with an existing 17,000 SCFM (27,285 Nm3/hr) Regenerative Thermal Oxidizer (RTO) that the company inherited with the plant. However, the engine test cell emission control issue was complicated by the water vapor emitted with the VOCs. Control of the CO emissions was not an objective for this application because its release was not a concern to any local regulatory authority.

The Solution

After a thorough technical evaluation, Anguil engineers chose a new 25,000 SCFM (40,125 Nm3/hr) RTO as the most cost-effective solution for the existing conditions.

The Result

Several factors affected this decision. The presence of a large percentage of water vapor in the process exhaust caused concern regarding the effectiveness of the concentrator type adsorption system. Vapor-liquid separators could be used to minimize the water introduced to the concentrator but the low winter temperatures would require the additional cost of heat tracing and insulation to prevent freezing, increasing the overall cost of the system.

A more suitable technology choice emerged in the RTO. Emissions from the test cells were still low and this technology is extremely cost-effective at low concentrations with 95% thermal energy recovery typically achieved and options for up to 97% thermal energy recovery available. However, the existing RTO coupled to the concentrator controlling the paint processing did not offer the needed capacity or the upgraded materials of construction to provide resistance to corrosion.

Anguil engineers presented their analysis to the customer with all the control options available and the optimal technology chosen for treating the engine test cell emission was a new RTO. The engineering study, which considered the high quantity of water vapor and CO emissions, determined that all ductwork between the test cells and the RTO must be constructed of stainless steel to prevent corrosion. The ductwork was also sloped back to the process entry stream to minimize carryover of excessive amounts of water to the RTO. The oxidizer’s internal insulation and inlet ductwork were also designed to process the high amount of water vapor to minimize erosion of the RTO insulation and corrosion potential of the steel.

The system operation is very energy efficient with thermal energy recovery of 95% or higher. The process air containing VOCs passes through vertical beds of ceramic media that alternately stores and releases heat to elevate the process air temperature before it enters the combustion chamber. Since RTOs have such high heat recovery, the process air can be heated to a value very close to the combustion chamber set-point temperature. Heat released from VOC destruction during oxidation further elevates the process air temperature to the point where the RTO is often self-sustaining with no auxiliary fuel usage.

With this system, they elected to use supplemental fuel injection (SFI) that reduces the point of self-sustained operation to a lower process VOC concentration. Burners are shut off during operation with SFI which minimizes the introduction of combustion air into the chamber, and further reduces operating fuel usage with a flameless design that eliminates NOx emissions from the burner, problematic in some RTOs.

The manufacturing plant is now able to meet compliance on multiple emission sources while saving capitol expense. First, by utilizing equipment inherited with their plant purchase, plus the operational cost savings on the newer more efficient RTO. An additional benefit with selection of an RTO was to the environment. Although not required, RTOs control the CO emissions along with VOCs from the test cells. This facility can accommodate future expansion and stay in compliance for many years to come.

The Challenge

The Challenge The Solution

The Solution