Multi-Staged Combustion or Selective Catalytic Reduction?

Comments Off on Multi-Staged Combustion or Selective Catalytic Reduction?The Challenge

Many industrial furnaces operate in oxygen depleted conditions, emitting high levels of ammonia, NOx, and other nitrogen-bearing compounds. This presents a significant challenge for manufacturers striving to meet air quality regulations and limit carbon output.

Emission streams that contain nitrogen bearing hazardous air pollutants (HAPs) cannot be thermally treated in a traditional oxidizer system without forming additional NOx, making adherence to an air permit difficult or impossible. In such cases, a secondary abatement device, downstream of the thermal oxidizer is required for additional NOx reduction.

Historically, the industry has relied on Selective Catalytic Reduction (SCR) systems to achieve this. The add-on technology injects ammonia or urea into the process stream before passing it through a specialized catalyst that converts the NOx into nitrogen gas (N2) and water vapor. However, this approach comes with significant operational burdens:

- The need for ammonia or urea storage, pumps, and customized control systems to maintain injection rates.

- High operating costs due to chemical consumption, catalyst maintenance, and periodic replacement.

- Fresh air must be added to dilute the inert process streams to safe levels, increasing the treatment volume and leading to condensation issues.

- Additional winterization equipment to prevent freezing in cold water climates.

It essentially requires a small chemical operation to remove the NOx and the staff to support it.

The Solution

Over the past four decades, Anguil has provided thousands of thermal and catalytic oxidizers around the world, many of which incorporated SCR technology. Recognizing the inefficiencies, engineers at Anguil came up with a better solution. The objective was to maintain very high levels of HAP removal, eliminate the catalyst and associated maintenance, prevent the need to dilute the stream making it safer to operate, and eliminate the use of add-in chemicals.

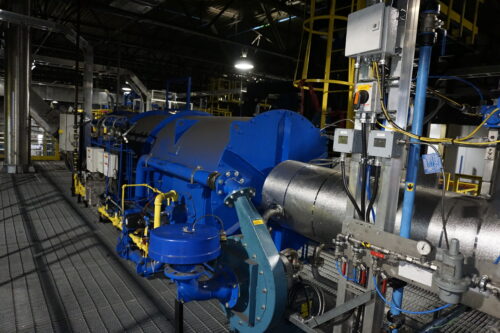

This solution was a Multi-Staged Direct Fired Thermal Oxidizer (MS-DFTO) – a groundbreaking approach that compartmentalizes the oxidation process across multiple temperature-controlled stages with varying oxygen levels, to dramatically reduce the formation of greenhouse gases.

In the MS-DFTO the nitrogen bearing HAPs are introduced into the first stage of the thermal oxidizer, the reducing zone, that operates at elevated temperatures, but without oxygen. This serves to disassociate the HAPs while not forming NOx from any nitrogen bearing compounds in the absence of oxygen. Special operational sequences ensure starved oxygen is maintained in the first stage. The high temperature, oxygen depleted gas leaving this first stage is then rapidly cooled in a second stage to near the oxidation temperature. At this cooler temperature, the gases are reintroduced to air in the third chamber where the complete combustion of compounds occurs. Design considerations are made to ensure that the temperature after oxidation does not escalate to where thermal NOx could be formed, generally above 1,800°F (982°C).

Specialized refractory insulation and highly automated controls for the various stages of the Anguil MS-DFTO minimize auxiliary natural gas consumption. Properly staging the operating conditions and temperature profile throughout the MS-DFTO will result in destruction rates of the hazardous compounds and volatile organic compounds with minimal NOx formation in a single system.

In select applications, a fourth stage of the MS-DFTO has been added to provide Selective Non-Catalytic Reduction (SNCR) as a safety factor to ensure even fewer NOx emissions. Experience has shown that these fourth SNCR stages are not necessary and rarely used even when supplied as the NOx emissions have always met permit requirements without the need for this polisher.

The Result

This staged combustor from Anguil is reshaping how industries approach greenhouse gas abatement from process furnaces. On this application, the Anguil MS-DFTO was treating 5,000 SCFM (8,025 Nm3/hr) of process air in a single abatement device with well over 99% HAP destruction and NOX emissions that were a small fraction of the allowable permit value. The equipment does not require chemical injections or active catalyst maintenance, meaning a heavily reduced operational cost relative to an SCR. Inert process streams can remain inert, meaning a safer system can be supplied that does not require upstream dilution. Treating a fraction of the air also means the upstream process ducting can be smaller, saving cost all around.

Industrial facilities continue implementing Environmental, Social, and Governance (ESG) strategies to comply with regulations, improve sustainability, and meet stakeholder expectations. This ESG initiative met those objectives and reduced equipment cost, footprint, and maintenance costs, while eliminating the carbon footprint from past chemical purchases.

Meeting the Challenge of EV Battery Recycling: An Innovative Solution

Comments Off on Meeting the Challenge of EV Battery Recycling: An Innovative SolutionThe Challenge

As the lithium-ion battery industry grows rapidly, old technology is being replaced with new. Furthermore, the lithium-ion batteries powering electric vehicles (EV’s) will not last forever. Due to degradation, the typical lifespan of an EV car battery is 10-20 years or between 100,000 and 200,000 miles. So, what happens to these batteries when they’ve reached the end of their life?

EV Battery Recycling is a growing market in the US, especially as more batteries will reach the end of life in the coming years. 11.3 Gigawatt hours (GWh) of EV batteries reached the end of life in 2022, with that number projected to rise to 138 GWh in 2030. With the current shortage of domestically supplied battery critical materials, recycling is even more important to provide additional supply sources. One US-based battery recycler is looking to build new facilities and expand their current ones but needed the expertise of Anguil Environmental Systems to ensure a sustainable process.

This company recycles household, industrial, and EV batteries, which all have similar recycling processes. First the batteries are disassembled into smaller units, which are then mechanically separated to recover components. Afterwards, hydrometallurgical treatment recovers the metals and plastics of lithium batteries to be reused in new products. Several steps of this process produce exhausts that need to be treated.

Anguil’s engineers were brought in to design a unique system for the customer that complied with local emission regulations. Their current VOC concentrations were up to 25% LEL (Lower Explosive Limit), but a destruction rate of at least 98% was required. The combination of a saturated process stream with incoming particulate meant that special design considerations needed to be made. These will ensure a long equipment life span and minimize system downtime.

The Solution

The Solution

These unique challenges lead Anguil’s team to select a Model 300 Regenerative Thermal Oxidizer (RTO). Due to the high moisture content in the customer’s airflow several parts of the system were constructed of stainless steel to provide resistance to corrosion including the process fan, diverter valve assembly, media support section and exhaust stack. An internal coating was also applied to the oxidizer chamber to provide additional protection.

To allow for processing of the spikes in VOC concentrations, a hot bypass duct system was included to bypass chamber gases directly to the exhaust stack, preventing an over-temperature condition from developing within the RTO. Prior to reaching the RTO, the process exhaust will pass through a filter in the upstream ductwork to remove any particulate.

The main process fan was sized to ensure enough inlet suction was available to overcome the planned upstream filtration and ductwork pressure losses. A local control panel near the RTO was to be included within a dedicated prefabricated room to provide protection against weather for personnel when using the panel HMI.

The Result

The RTO was chosen for this application, as it was the most cost-effective solution over direct-fired oxidizer systems and catalytic oxidizer systems. A direct-fired oxidizer would have consumed a high amount of supplemental fuel due to the high flow volume and lower VOC concentrations. A catalytic system was ruled out because of the higher initial cost due to the amount of catalyst required and the cost of periodic catalyst replacement.

As the world transitions to electric vehicles, there is an increasingly crucial need for efficient and sustainable battery recycling. The growing number of end-of-life batteries presents a unique opportunity and challenge for this industry, and Anguil Environmental Systems is ready to step in to address this challenge, providing tailored solutions to ensure a safe and environmentally responsible recycling process. By designing state-of-the-art pollution control systems, Anguil helps our clients meet stringent emission regulations while optimizing the recycling process. Our innovative solutions not only address the immediate needs of the industry but are also paving the way for a more sustainable future, where valuable resources can be recovered and reused, contributing to a circular economy.

Silicon Powder Revolution: Powering the Future of Energy Storage

Comments Off on Silicon Powder Revolution: Powering the Future of Energy StorageThe Challenge

In the ever-evolving landscape of energy storage technology, the demand for efficient and sustainable solutions has intensified, prompting a significant shift in the materials utilized for lithium-ion batteries. Anode active materials (AAM) are generally made from carbon-based materials like graphite, silicon, or a combination of the two, with graphite having been the most used anode material due to its high electrical conductivity, low cost, and stable structure. However, silicon carbon-based powder offers 10 times higher capacity and up to 50% more energy density than graphite, a critical solution in this transition from lithium-ion batteries, and a sign that lithium-silicon batteries are the future of energy storage technology.

The Solution

This was a challenging design due to the nature of the process. An inert process stream at a high temperature would be exiting the kilns and there were safety concerns due to the explosive nature of the pollutants and silane. An important aspect of the project was that the equipment needed to handle a significant amount of inorganic particulate that would be formed during the oxidation process. Maintaining high equipment uptime is key for both companies, so on-line cleaning was required.

Anguil was able to work with and collaborate with the kiln original equipment manufacturer (OEM) to give an integrated system on the larger lines. After the pilot line was installed and achieved the guaranteed performance requirements, Anguil was chosen to design and install two larger units on full-scale production lines for the customer.

The Result

For the full-scale production lines, Anguil designed, fabricated, and installed two (2) 9,000 SCFM DFTOs with downstream fabric filter dust collectors. These designs were created to allow for a range of operating conditions to be handled. The layout was also customized to meet site installation requirements and allow for additional future lines.

The full-scale system incorporated many design enhancements compared to the pilot line to ensure equipment uptime. Anguil performed multiple Computational Fluid Dynamics (CFD) analyses on the full-scale DFTO design and collaborated with the customer to optimize the performance and design. Anguil’s ability to provide a custom solution was critical to the customer, and much time and care were utilized to optimize the design to craft a system that can be applied on all future lines. Important design changes increased residence time to meet destruction requirements. These enhancements allowed for on-line cleaning of the heavy inflow of particulate.

The AAM market is expected to continue to grow and evolve swiftly as we discover new information about energy storage technology. Pollution from the process technologies and techniques used to produce batteries can be detrimental to our air, water, and soil if the proper abatement technologies are not applied. Fortunately, Anguil Environmental Systems offers effective, proven technologies that have been applied throughout the production chain; from material mining to powder production, anode coating, battery recycling, and component manufacturing. Anguil is well-positioned to support this ever-evolving market and develop alternate-fuel oxidizer technology.

Creating Air Pollution Control Solutions for Carbon Neutral Graphite Mining

Comments Off on Creating Air Pollution Control Solutions for Carbon Neutral Graphite MiningThe Challenge

The markets for lithium-ion batteries, electric vehicles, and fuel cells are increasing exponentially, meaning the demand for graphite is higher than ever before. Lithium-ion batteries consist of four components: electrolyte, separator, cathode, and anode. Every component is essential to the battery, meaning it cannot function without one. Graphite is the single largest mineral component of the battery, making it an essential material in manufacturing lithium-ion batteries and electric vehicles that rely on batteries.

The anode stores lithium ions when the battery is being charged and then releases them, allowing currents to pass through an external circuit. Graphite powder is currently the most-used anode material due to its composition and storage capacity.

With no common alternative to graphite, graphite mining has become more essential. Mining natural graphite offers lower carbon emissions than the energy-intensive production of synthetic graphite. New companies are being formed and existing companies are ramping up production by creating new mines and production lines. However, more mining activity leads to more emissions and a greater carbon footprint for these companies.

Anguil Environmental Systems recently helped lower carbon emissions from the production of battery material with the installation of air pollution control equipment at a natural graphite mine in North America. Increased government regulation on emissions and the desire to create a sustainable product motivated this company to install a custom-designed system from Anguil.

The Solution

Increasing government regulations on emissions often drives companies to install air pollution control equipment. However, more companies are being motivated by ESGs, or Environmental, Social, Governance, which is an assessment of a company’s ability to limit its environmental and social impact. This graphite mining company is ahead of many, as they have already achieved carbon neutrality and are hoping to be Net Zero by 2030. So, when installing new production lines, it was no question that they were going to install pollution control equipment.

This specific plant produces high-quality Coated Spherical Purified Graphite (CSPG) for lithium-ion battery anodes. Due to the unique nature of their process, Anguil recommended a demonstration line, or pilot unit, to prove system effectiveness and efficiency for the specific graphite qualities at the processing plant. The emissions to be treated were from a pusher furnace/kiln that processed graphite and pitch. The furnace exhaust was inert (no oxygen) and at a high temperature, with the possibility of condensable organics. The furnace hood exhausts, which would contain oxygen and trace VOCs, also needed to be sent to the oxidizer. This meant Anguil’s engineers had to ensure good mixing of the two process streams with an additional third fresh air stream to be added to ensure the proper oxygen needed for oxidation. The equipment selected was a 500 SCFM (790 Nm3/h) Direct Fired Thermal Oxidizer (DFTO), which is capable of over 99.5% VOC destruction efficiency. The DFTO was coupled with a proprietary inlet mixer to alleviate the mixing and condensation concerns. The mixer was designed to minimize cold spots when the air streams were introduced to the process stream.

Anguil utilized CFD modeling to ensure the proposed design would have proper mixing and flow distribution to maintain emission destruction requirements and efficiency parameters.

An increased residence time in the combustion chamber was also added to meet destruction requirements. A horizontal combustion chamber allowed for the system to be installed above the furnace inside the facility. An induced draft configuration was incorporated to keep the oxidizer system operating under negative pressure for health and safety concerns. Anguil worked closely with the furnace supplier to ensure a seamless integration.

The Result

The plant runs on renewable electric hydropower, which meant the energy use of the equipment had to be minimal. The DFTO operates on propane that is used for the initial equipment startup, and to maintain a pilot flame only. The high VOC content in the process means that little to no supplement fuel is needed to keep the oxidizer at operating temperature during normal operation. This results in essentially no additional greenhouse gas emissions to reach their goal of carbon neutrality. The burner will be operating on pilot flame only during normal production and the DFTO controls allow the oxidizer to automatically adjust to changing inlet conditions to ensure the minimum amount of supplemental fuel is used. Anguil is working on a lower carbon footprint oxidizer for the future full-scale production lines that will be implemented at this site. The new design will eliminate the carbon dioxide formed from a typical gas-fired burner. Despite facing obstacles due to COVID-19, Anguil was able to install a high-quality system and offer professional support during the installation and commissioning stage. Anguil’s extensive network of service engineers was able to overcome the difficulties of travel during the COVID lockdown period.

As the company gears up to create full-scale production lines, the Anguil air pollution equipment will keep emissions below government regulations. Anguil technology can be adapted to meet customers’ energy needs and help them transition to even lower carbon footprint-oxidizers in the future.

Planning for Increased Can Capacity Pays Dividends

Comments Off on Planning for Increased Can Capacity Pays DividendsThe Challenge

A US-based can manufacturer recently upgraded their regenerative thermal oxidizer (RTO) in order to increase the maximum flow to the unit. The original oxidizer was designed and installed by Anguil back in 2015, with the intent to eventually upgrade. Anguil was able to successfully retrofit the equipment while overcoming the challenges that ensued. Through calculations and cost comparisons provided by Anguil, the customer was able to make practical, cost-effective, and environmentally friendly decisions to meet their specific needs.

“The plant had always planned to add additional lines so there was capacity built into the oxidizer and dust collector,” said Charlie Fields, an aftermarket application engineer at Anguil. The additional coating line the customer wished to add would send a total of 41,500 standard cubic feet per minute (SCFM) to the equipment, an increase of over 20,000 SCFM. Though the equipment was oversized initially to accommodate added flow, “the new production line would have exceeded the capacity of the RTO,” Fields continued.

The Solution

To solve the issue, Anguil proposed multiple options to the can manufacturer. The first option was to install an additional, smaller oxidizer to handle the additional flow. However, this would have been costly to purchase and operate, as the plant would have had two different-sized RTOs. Furthermore, there was no available space to install a second RTO. The second option was to install a new, larger oxidizer to handle the total flow. However, removing an existing, working oxidizer and decommissioning it would be very expensive, along with the cost of buying and installing a much larger oxidizer. This option would have also presented production challenges as many can making plants cannot run without abatement systems in place. After collaboration between Anguil and the can maker, they decided on a third option.

The Result

The chosen solution was to install a concentrator wheel to concentrate the cool air streams to allow for more capacity in the RTO. The selected 15,000 SCFM concentrator wheel concentrates the flow from an existing dust collector and sends 1,500 SCFM of VOC-laden air to the RTO inlet. This ensures that all the lines can be used simultaneously. “We decided to run all the cool streams through the wheel to concentrate them and provide additional capacity now and in the future,” Fields said. “All the hot sources were run directly to the RTO.” The operating costs of this RTO/concentrator system were much lower than those of the other proposed systems: small/large RTO system and 1 large RTO system.

Once the retrofit decision was made, Anguil provided a turnkey project that included design, engineering, equipment selection, fabrication, installation, and startup services. With the purchase of an Anguil installation, the can manufacturer received a field service team to provide support and get the project finished and the equipment online.

Keeping Battery Production Profitable and Green

Comments Off on Keeping Battery Production Profitable and GreenBatteries have become a key contributor in the world’s energy transition and critical in the effort to slow climate change. As a result, battery manufacturing technologies and techniques are constantly evolving as producers look to remain competitive, increase storage capacity, and improve efficiency while decreasing battery size and weight. For instance, some producers are turning to a silicone-based anode material to increase battery output and reduce cost; others are exploring mining lithium from seawater to alleviate supply issues. When combined with an unprecedented increase in demand and subsequent production increases, it is fair to say that manufacturers are in a constant state of change. And it is not slowing down: some experts estimate the lithium-ion battery market alone will expand 18% by 2030. In short, we need more energy storage, in smaller batteries, at lower costs.

Lithium-ion batteries are considered the most energy-dense and longest-lasting rechargeable batteries currently available. The process of making them varies, but in general it consists of mixing raw materials followed by a series of coating, laminating, drying, cutting, winding, welding, sealing, forming, pre-charging, and degassing before a final test. However, when battery advancements occur, many of these existing production inputs and manufacturing practices need to change quickly. This can include raw material adjustments, production equipment modifications, or a change in coating techniques, just to name a few. The pollution control technologies employed at the battery manufacturing facilities are also affected by the upstream changes but are often an afterthought by plant personnel.

One synthetic graphite anode powder manufacturer was modifying their furnaces to accommodate new products for lithium-ion battery manufacturing. Because their production facility was in a non-attainment area, per the United States Environmental Protection Agency (EPA), air quality standards required them to take special precautions. This meant a Title V permit would be required, as they have the potential to emit more than 100 tons per year (TPY) of VOCs, more than 10 TPY of any single HAP, or more than 25 TPY of any combination of HAPs.

This manufacturing plant in the United States produces high-performance anode material for lithium-ion batteries. A key component of lithium-ion batteries is the anode which stores and releases the lithium ions. Graphite is currently the most commonly used anode material. The process starts with a petroleum coke, which is formed into a synthetic graphite through graphitization. During operation, between 12 to 18 graphite furnaces, which are modular in construction and electrically heated utilizing local hydropower, are needed to meet the production demands.

This facility was no stranger to environmental stewardship. In years prior, they completed an Environmental Assessment to secure financial assistance from the Department of Energy and participate in the American Recovery and Reinvestment Act, which aims to accelerate the development and production of electric-drive vehicles systems to substantially reduce the United States’ consumption of petroleum. In fact, the site itself remains nearly 70% greenspace today.

In keeping with the company’s sustainability goals, they immediately began the search for an effective and efficient air pollution control system. As is the case with many manufacturing operations, process emissions are best destroyed using thermal and catalytic oxidation technologies where time, temperature, and turbulence convert VOCs and HAPs to heat, water vapor, and small amounts of carbon dioxide (CO2).

Widely considered the most energy-efficient oxidation technology, the Regenerative Thermal Oxidizer (RTO) uses these oxidation principles with a unique heat recovery component. Highly effective ceramic media within the oxidizer captures heat from emission combustion and reuses it to preheat incoming pollutants. The RTO also uses uniquely designed poppet valves to divert process air into and out of the oxidizer, properly balance emission loading, maintain destruction efficiency, and optimize heat recovery. Most RTOs are a two-bed design, but they can be designed in a multi-chamber configuration to accommodate larger airflows and achieve destruction efficiencies above 99.7%.

Given the emission loading and low process temperature, the company chose the RTO for its high destruction capability above 99%, and a preowned system was selected to meet their aggressive timeline for compliance. The refurbished, two-bed RTO from Anguil Environmental Systems was delivered, installed, and operational in less than ten weeks. It treats up to 5,000 standard cubic feet per minute (SCFM) of process flow containing methane, ethylene, acetylene, carbon monoxide (CO), benzene, aromatic hydrocarbons, and aliphatic organics from the electrically heated furnaces and corresponding collection hoods. Dilution air at each furnace was added to keep the overall lower explosive limit (LEL) in the duct system below 25%, per code.

Advanced programmable logic controls record vital oxidizer operating parameters for regulatory reporting and ethernet communications allow for remote diagnostics and service support. A variable frequency drive aids in minimizing operating cost by providing fan turn-down when only low airflow is required in the RTO.

Air pollution and greenhouse gas emissions from this facility remain extremely low due to the efficiency of the pollution control system and utilization of hydropower for the process furnaces. A preowned abatement system was selected to meet an aggressive timeline at this particular facility. However, battery manufacturers all over the world are employing various thermal oxidizer technologies to meet their unique process conditions. For instance, some silicone-based anode precursor manufacturers are utilizing direct-fired oxidizer technologies with downstream particulate control to handle silicon dioxide emissions and remain in compliance. Regardless of the process, oxidizer selection is application specific and should be based on emission constituents, process parameters, efficiency needs and regulatory requirements.

Odor Elimination: Rendering

Comments Off on Odor Elimination: RenderingSummary

In the Rendering Industry, odor control equipment has been in use since the early 1970’s about the same time Anguil was formed and started serving clients

As technologies evolved, fire tube boilers that utilized the waste heat of the afterburners were added to produce steam for the steam intensive plant process. The use of the waste heat boilers were the first step in heat recovery of the afterburner. The addition of the waste heat boiler to an afterburner would typically make the overall system efficiency of the two components in the high 70% to low 80% range. However, the overall system efficiency was only this high if the total production of steam from the waste heat boiler was constantly used. Intermittent use of the steam production severely lowered the overall system efficiency and increased the operating cost.

Other applications of different technologies included the use of Thermal Recuperative Oxidizers, which utilize a shell and tube stainless steel heat exchanger. The Thermal Recuperative Oxidizers were not used with waste heat boilers due to their lower outlet exhaust temperatures, but still utilized Economizer units for pre-heat of make-up feed water. Typical heat recovery performance of a shell and tube heat exchanger was around 60 – 70%. The lower efficiency of the shell and tube type heat exchanger vs. a waste heat boiler still averaged to a lower annual operating cost on applications were large boilers were already existing, and steam generated by a waste heat boiler could not be utilized on a continuous basis.

The Challenge

Rising energy costs and the social pressures for improved Environmental Social Governance (ESG) around one of the oldest recycling industries, Rendering, has led to the need for implementation of better environmental controls. With residential areas encroaching on Rendering plants, odor control of storage, loading, grinding, and transport areas has become important. The larger air flows associated with controlling these areas make the use of higher efficiency technologies a must in order to conserve energy and meet today’s carbon reduction goals.

The Solution

Regenerative Thermal Oxidizers (RTOs) are becoming more commonplace to solve these challenges, but the importance of an experienced team to supply this

The Result

With the multi-stage solution, the initial Venturi Scrubber uses a centrifugal action to ready the gas stream before entering the first-stage Scrubber that treats the ammonia. Leaving the top of the initial packed tower into the bottom of the Hydrogen Sulfide second-stage section, the waste gas is further prepared for final treatment of Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs). A three-canister RTO provides a means to eliminate a short duration “puff” of untreated odors from the RTO during valve cycling. With such high intensity odors in a Rendering application, it is vital to remove greater than 99% of any entering waste components. Leaving the exhaust stack of the RTO, final regulated emission levels are met while minimizing CO2 production with the highly energy efficient RTO technology.

Project Highlights

- Stainless steel material is used to maximize equipment life when exposed to incoming acidic gas streams

- Specially designed ceramic media heat recovery beds in the RTO to better resist particulate plugging

- Properly sized burner and combustion chambers for maximum performance and flexibility for fluctuating operations

- Proven controlled bake-out program to clean RTO ceramic media to maintain optimal performance

No Half-baked Idea

Comments Off on No Half-baked IdeaThe Challenge

Ready-to-eat meals, freshly baked goods, and essential groceries draw loyal customers to a chain of convenience stores; they just also happen to sell gasoline. The chain’s nutritious food is locally sourced, processed, and packaged for distribution to almost 1,000 stores in the United States. This company is uniquely positioned as vertically integrated, whereas much of the supply chain is owned by a single corporation serving a common market and customer segment.

One such vertical operation is a commercial bakery that supplies the company stores with fresh bread, bagels, buns, doughnuts, muffins, and snacks. It is a state-of-the-art facility focused not only on quality, but operational energy efficiency and a low carbon footprint. When the company decided to increase capacity, they took a wholistic approach to the design and layout. New bread and bun ovens were purchased along with proofers which are large enclosures kept at elevated temperatures to help dough rise. Most commercial bakery ovens and the corresponding proofers rely heavily on natural gas or electric elements to generate heat for baking the products.

While working with local regulators to satisfy air pollution control requirements for the new lines, company engineers explored the utilization of waste heat from pollution control systems. Oven exhaust contains Volatile Organic Compounds (VOCs) like ethanol, as well as odors that must be treated to comply with national emission standards.

Like many other industries, food processors often find that the best available control technologies for emission and odor abatement are thermal and catalytic oxidizers. Oxidation systems use time, temperature, and turbulence to break down pollutants into Carbon Dioxide (CO2), heat, and water vapor. This bakery was particularly focused on minimizing the CO2 output from the planned oxidizer installation by utilizing the heat from combustion. It would not only save operating costs, but also keep with the company’s commitment to do right by customers and the community.

The Solution

Anguil Environmental Systems was one of the first air pollution control system suppliers in the early 1990s to design and install oxidizers that met regulations limiting bakery oven emissions and odors. Three decades later, Anguil remains a leading supplier of both thermal and catalytic oxidizers to the baking industry. Regenerative Thermal Oxidizers, or RTOs, have been increasingly used on commercial ovens for their energy-efficiency operation. RTOs are typically 95% thermally efficient whereas catalytic oxidizers range from 60-80%. However, catalytic oxidizers are still widely applied at bakeries due to their lightweight construction which makes a rooftop installation more feasible, putting them near the ovens while eliminating costly duct runs.

This bakery was like many others in that regard; a roof installation made catalytic oxidation the most logical equipment selection. Two Anguil Model 50 (5,000 SCFM capacity) catalytic oxidizers would be installed, one for each oven, on dedicated roof platforms. During operation, ethanol-laden oven gases are pushed into a stainless-steel, shell-and-tube heat exchanger inside the oxidizers via a system fan. The contaminated airstream is progressively heated while traveling through the heat exchanger towards the combustion chamber. The cleanable, heat exchanger allows for self-sustaining operation with no auxiliary fuel usage at Lower Explosive Limits (LEL) levels of 8-12%. At the burner, the process gas is raised to the catalyst operating temperature. As the heated gas passes through the catalyst, an exothermic (heat releasing) reaction takes place as the pollutants are destroyed. The hot, purified air then passes through the opposite side of the internal heat exchanger and transfers thermal energy to preheat the incoming air.

This environmentally conscious bakery was interested in further reducing operating costs and energy consumption. Therefore, Anguil recommended and designed a secondary heat recovery system to capture additional waste heat from the two oxidizer stacks. Finned tube heat recovery coils with propylene glycol-heated fluid were installed to recover over 2.5 MMBtu/hr from the oxidizers and provide a heat source for the proofers.

The Result

The Anguil oxidizers achieve over 98% destruction efficiency of the ethanol emissions while reducing the carbon footprint of the bakery’s operations. The systems incorporate a self-cleaning ceramic filter, which prevents grease from plugging or fouling the catalyst. The Anguil design also ensured that the abatement devices would have no back pressure in the ductwork which could impact oven performance or product quality.

Concentrated on Maximum Savings

Comments Off on Concentrated on Maximum SavingsThe Challenge

A family-owned manufacturer of metal wall and roofing systems in the Midwest was looking to expand their production capabilities while taking advantage of local utility rebate programs. Their existing operation contained three painting booths venting directly to atmosphere. As a part of the expansion, they planned to install two new paint booths, which would require them to install pollution abatement equipment.

Their application presented the following design challenges for the required emission control solution:

- The five paint booths represented a very large process stream containing volatile organic compounds (VOCs) including toluene, xylene, and

ethylbenzene.

- The solution needed to process up to 90,000 SCFM of VOC-laden air with a minimum of 95% overall destruction efficiency.

- Space was also a major concern, as the equipment needed to fit in a tight space.

- They wanted to maximize energy rebates through their local utility provider, who offered prescriptive measures for the installation of pollution control equipment.

They solicited proposals from several air pollution control equipment suppliers including Anguil, another Midwestern family-owned business.

The Solution

With such a large airflow from five paint booths, Anguil engineers quickly identified the emission concentrator system as the most cost-effective choice, proposing a 90,000 SCFM Rotary Zeolite Emission Concentrator Wheel combined with a 7,500 SCFM Regenerative Thermal Oxidizer (RTO).

Even though RTOs are extremely efficient and effective destruction devices, they rely on a steady stream of process emissions to fuel combustion of incoming contaminants. When coupled with a concentrator, the oxidizer consistently receives highly concentrated streams in a much smaller volume.

The selection of concentrator is easy to justify at this flowrate when compared to a standalone 90,000 SCFM RTO with similar footprint. While the capital cost of a concentrator and oxidizer combination is typically more expensive than the RTO without concentration, the proposed system would use dramatically less energy, which would reduce operating costs and greenhouse gas emissions. The reduction in natural gas and electricity usage would also make the manufacturer eligible for energy rebates in their state.

Their local utility company offers rebate program for customers that implement energy efficiency measures. Their current program has prescriptive measures for the installation of gas fired equipment like thermal and catalytic oxidizers. Under this program, the customer was eligible for a $37,500 rebate ($5.00/cfm for 2 shift operation x 7500 SCFM RTO).

Anguil’s local sales representative approached the utility company engineers with the possibility of doing a custom energy analysis since the concentrator system was even more efficient than a standard RTO. Anguil showed the energy consumption of the concentrator system and modeled it against a 90,000 SCFM RTO. This showed that the concentrator system would use 771,450 kWh/ year ($0.05/kWH incentive) and 51,393.82 MCF of natural gas/year ($3.50/MCF incentive). This calculated to a $218,000 rebate.

The utility company engineers brought the project to an external consulting company that provides oversight and regulatory compliance for the energy providers and their rebate programs. The consulting company agreed that the baseline should be a recuperative oxidizer, a less thermally efficient style of thermal oxidizer. This brought the energy savings up to 689,788 kWh electric and 209,094 MCF in natural gas savings for a total energy incentive of $766,319.00! However, there is a $300,000 cap per customer for natural gas payouts.

The Result

- With persistence and a strategic focus on maximizing the energy rebate program, Anguil was able to secure the project and increase the customer’s total project rebate from an initial $37,500 to $300,000 – that’s an additional $262,500 savings!

- The utility company determined to pay approximately half of the incentive for the program year 2020 and the balance in 2021 to better accommodate

their savings goal and this also removed the payout cap so that the customer received the full amount through both program years.

- Since this was the customer’s first experience with emission control equipment, Anguil provided 10 days of start-up assistance and staff classroom training to ensure familiarity with their new state-of-the-art pollution control system.

Anguil has built upwards of 60 emission concentrator installations in the past five years and is well-regarded as an industry leader with this technology. Anguil’s extensive experience with emission concentrators and successful advocacy for a significant custom energy savings program gave the customer confidence in their selection for the project. In addition, Anguil’s similarity to the customer’s Midwestern, family-run business assured that they would be taken care of and would enjoy accessible communication and project transparency.

Getting What You Pay For

Comments Off on Getting What You Pay ForThe Challenge

Background

For any production facility, up-time is paramount. Machines churning and grinding equals profit, and the sound of silence is typically less desirable. For processes that generate dangerous Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs), uptime can be limited by both control of the emissions and safety considerations for your employees.

A tape manufacturer faced such a problem. They required emission control of solvent VOCs from their tape making process. They also wanted to provide a Permanent Total Enclosure (PTE) around their equipment to protect the health and safety of their facility, their employees and maintain a nuisance, odor-free environment.

As experts in the tape industry, they rightly reached out to a small, local engineering firm to design the PTE and size the VOC abatement device. Further, sensitive to their business needs, they approved the lowest cost solution using minimal ductwork and the purchase of a used oxidizer.

However, the decision to entrust their production uptime, worker safety and EPA compliance to an inexperienced consultant

resulted in undersized and malfunctioning equipment, which proved to be disastrous. It is never a best practice to let cost

be the only driver when selecting a technology which may impact production.

A Costly Low-Cost Decision

After having the PTE constructed and the used thermal oxidizer installed, the manufacturer ramped up production and rapidly became aware that the system was not working as sold. The number of air exchanges in the room was inadequate, requiring the employees to labor in gas masks. Moreover, though the used thermal oxidizer suffered from frequent shutdowns, the manufacturer would not support the equipment. More importantly, even when operating, the air pollution control (APC) device could not meet the Destruction Removal Efficiency (DRE) permit requirements, resulting in intermittent production uptime and ultimately a total facility shutdown coupled with the largest non-compliance fine ever levied by the state.

The Solution

A Need For Trusted Expertise

To resolve the situation, the manufacturer brought a more established and experienced consulting firm on board, who immediately realized the capture and abatement system was woefully undersized. The Engineering, Procurement, and Construction (EPC) firm, after putting together new design specifications, reached out to Anguil to assess the abatement device. Anguil visited the site, spoke with the manufacturer concerning their project needs and determined that a Model 50 Regenerative Thermal Oxidizer (RTO) was the ideal solution.

In addition, in the interim prior to the new equipment install, Anguil was asked to try and get the used thermal oxidizer operational. However, it was found the fuel train did not contain the proper valves to control the burner. A plastic bottle cap had been installed in one pressure regulator in an effort to provide enough supplemental fuel. In addition, the wiring for the process damper had never been completed, rendering it inoperable. This last situation is a significant and potentially explosive safety concern.

Despite these challenges, Anguil was able to get the used competitor’s unit operating safely and sufficiently to meet most of their current tape orders. However, the manufacturer had to temporarily relocate production to their overseas facility to meet domestic demand during reconstruction of the PTE, ductwork and installation of the new

Anguil RTO, causing significant business implications including temporary assignment of domestic personnel overseas, increased shipping costs, uncertain lead times as well as all the headaches and hassles coming with coordination of the effort.

The Result

In order to meet the deadline established by the regulatory body to bring the facility back into compliance, Anguil was able to adjust their manufacturing schedule to complete the RTO with sufficient time to perform a full shop test prior to shipping. The unit was shipped, installed and brought up to temperature in a few hours during fresh air commissioning. As soon as process air was sent to the RTO, the Anguil unit met DRE expectations from day one, allowing the facility to ramp up production and provide the desired level of worker safety. Further, because the oxidizer was properly sized (with room for expansion), the manufacturer was able to keep production within normal operating hours and eliminate overtime costs.

If you have a critical production process where every minute of downtime costs you money, don’t use cost as the only decision making criteria. Rather, select a system which meets your production needs, has demonstrated reliability and long-term support from the supplier. If you value uptime, call Anguil today for your VOC and HAP emissions control needs. Sleep well at night knowing that your Anguil air pollution control device will keep you up and running.

The Solution

The Solution

ethylbenzene.

ethylbenzene. their savings goal and this also removed the payout cap so that the customer received the full amount through both program years.

their savings goal and this also removed the payout cap so that the customer received the full amount through both program years.