How to Select the Right Pollution Control Technologies

Leave a CommentAir pollution can cause both long- and short-

The Power of Many – Expanding Possibilities of Remote Connection

Leave a CommentEstablishing a Remote Connection to your oxidizer is one of the most critical service enhancements you can make.

Manufacturers understand that establishing a remote connection with pollution control systems and process equipment is essential for business continuity. For Anguil clients with remote connection capability, it is both a lifeline during system upsets as well as a “force-multiplier,” akin to getting the experience and knowledge of several engineers on site for the price of one.

How is Remote Connection Typically Used?

Anguil generally uses remote assistance in our Field Service and Engineering departments to connect with equipment controls and make program changes or

We can accomplish even more equipment troubleshooting if the customer has an employee we can direct on what to physically check. In these cases, we can solve problems very fast, saving a potentially costly service visit or solving an equipment emergency when time cannot wait for the arrival of our service personnel.

Remote Connection in Uncertain Times

While remote connection has been a standard inclusion with Anguil equipment for many years, it gained elevated significance during global pandemic uncertainty when travel and many businesses were shut down. While Anguil remained open as an essential business, remote connection enabled us to stay connected to our customers and even support them in new ways, including “site” supervision.

For almost every aftermarket project requiring equipment work, Anguil sends a Field Service Engineer (FSE) to site for project supervision. However, during the COVID-19 global pandemic, Anguil was unable to go to a customer’s site due to COVID-19 safety restrictions at the plant. The project was a complex internal heat exchanger replacement, which required the removal of a large portion of ductwork attached to the system, electrical, and structural steel. This undertaking normally would have required an FSE onsite for up to a month.

The pandemic restrictions certainly presented a challenge to our aftermarket team, but at Anguil, we do whatever it takes to deliver for our customers.

Remote Connection Saves the Day in a New Way

Fortunately, the customer had remote connection established with Anguil. Our Aftermarket team decided to leverage this capability in a new way: remote installation supervision. With the customer onboard, our team strategized on the best execution strategy. A technical and mechanical package was put together

for the contractor to follow and conversations during the installation were on an as required basis. Most importantly, the remote installation approach offered additional flexibility with staffing: instead of assigning an FSE for project supervision, the Aftermarket team assigned the Project Engineer.

There were multiple benefits to this approach as the Project Engineer has much more intimate knowledge on the work being done. He completed many Solidworks models and drawings to guide the customer on how to remove and replace the heat exchanger. The Anguil Engineer was also able to monitor their

progress remotely at various points with a check in video call and resolve technical issues with the customer at their pace. At the same time, sending the Project Engineer to site to supervise would not be ideal for Anguil or our other Aftermarket customers as he could not keep up on his other projects while on site.

Remote installation supervision also softened the blow of other project complications. The customer faced many personnel and weather issues during installation. COVID-19 shut the plant down in the middle of the project for two weeks. A snowstorm shut the plant down for a couple days. If Anguil had an FSE onsite during this time, they would have been stuck in a hotel for that amount of time.

Across the board, leveraging remote connection was a win-win for everyone. Due to the nature of this project and the savings incurred during remote assistance, Anguil was able to issue a credit to the customer worth over $12,000! The heat exchanger installation was successful and the customer was very pleased.

Interested in Remote Connection for Your Oxidizer System?

Remote connection capability is not just for Anguil systems! With a simple evaluation, Anguil can determine what needs to be done to get your oxidizer connected to our team of experts. Once online access is established, we can troubleshoot existing issues and help prevent future malfunctions. Get in Touch with Anguil’s Aftermarket team to learn more about adding remote connection capabilities.

How Do Regenerative Thermal Oxidizers Work

Leave a CommentEffective air pollution control is important in modern industrial facilities where the goals of ensuring regulatory compliance, minimizing environmental impacts, and maintaining a healthy bottom line, are all closely interlinked.

Staying Ahead of Evolving EtO Regulations

Leave a Comment EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

Are you ready for the increased compliance challenges?

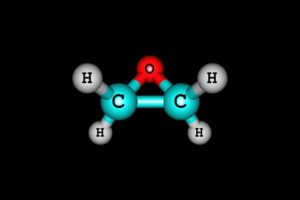

Why is everyone talking about ethylene oxide (EtO)? According to recent scientific studies, EtO is a more dangerous carcinogen than previously thought. Results from the latest National Air Toxics Assessment (NATA) have made EtO an increased focus of concern for the EPA and state regulators. For sterilization companies, this understandably makes you concerned about the safety of your employees and community, as well as your reputation.

In many cases, the traditional abatement technologies such as wet scrubbers and dry sorbents cannot meet the new EtO destruction requirements.

How does your abatement strategy measure up? How do you ensure that your abatement technology is up-to-date and meeting compliance requirements? With so much to lose, why take the risk with an unproven supplier?

A Proven EtO Abatement Equipment Design

Catalytic Oxidizers are one of the most widely accepted control technologies available to control VOC emissions from the EtO sterilization processes.

Anguil systems ensure zero leakage of EtO from the oxidizer and safe operation by integrating the peak shaver, a packed tower counter-flow water scrubber that absorbs ethylene oxide gas into the water by ensuring a high contact area between the gas and the water, preventing unsafe, high concentration conditions.

Sterilizers cannot afford to take the risk on an unproven company. We are proud of our reputation in the industry and our solutions that help ensure safer communities and sterilization operations. Learn more about our sterilization solutions here.

ANGUIL SYSTEM DESIGN FEATURES

- FLEXIBILITY: Base Metal Catalyst offers a large operational temperature window for flow and concentration variations

- COMPLIANCE: Horizontal Catalyst Tray Configuration avoids catalyst bed bypassing per NESHAP requirements

- PERFORMANCE: Leak-and-Dye Tested Shell & Tube Heat Exchanger guarantees 0% leakage of VOC-laden air into clean airstream, reduces operational costs

- SAFETY: Induced Draft Fan functions as a failsafe to prevent leakage into work environment

- DURABILITY: 304L SS Construction With Outer Aluminized Steel Frame increases equipment life, provides low-cost maintenance

- EASE OF USE: PLC With Human Machine Interface and Remote Connectivity System troubleshooting, alerts operator of equipment shutdowns

- ON SCHEDULE: Pre-Assembled, Wired, and Tested Prior to Shipment, can be installed within tight time restrictions due to high production levels

- EVEN, SAFE VOC LOADINGS: Integrated Peak Shaver evens out fluctuations in contaminant levels to a steady state, preventing unsafe, high concentration conditions

Anguil Announces Multi-million Dollar Order for EtO Sterilization Plant

Starting 2021 strong, Anguil announced a multi-million-dollar order for a 15,000 SCFM Catalytic Oxidizer with a Peak Shaver for a new ethylene oxide (EtO) sterilization plant. Anguil’s diversity of experience and wide breadth of technology offerings make us the popular industry choice for the nuanced and varied needs of the pharmaceutical industry where compliance is critical.

Learn more about our solutions for the pharmaceutical industry.

Have an Existing EtO Abator?

If you already have a pollution abatement system on your EtO process, Anguil’s suite of Aftermarket Services can ensure your equipment is optimized for

General Services

- 24/7 Emergency Service

- Routine or Troubleshooting Visit

- Operator Training

- Wastewater Treatment System Maintenance

Retrofits & Upgrades

- Increased Air or Water Flow Capacity

- Improved Destruction Efficiency

- Controls Enhancements

Preventive Maintenance

- Preventive Maintenance Evaluations

- Maintenance Contracts

- Predicative Maintenance Monitoring

Spare Parts

- Individual Spare Parts

- Recommended Spare Parts Packages

- Catalyst & Media

Explore Anguil’s Aftermarket Solutions.

Anguil’s engineers will diligently analyze your challenges and requirements to recommend a comprehensive, turn-key compliance solution. Our suite of quality engineered, air pollution control technologies will efficiently solve your pollution control challenges no matter the complexity. Contact Us to get started with your application.

Webinar: Empowering Environmental Technologies with the IIoT

Leave a CommentWebinar: Empowering Environmental Technologies with the Industrial Internet of Things (IIoT)

When: Wednesday December 2, 2020 / 1:00 PM – 2:00 PM CDT (2pm ET / 11AM PT)

Presented by Environmental Energy + Leader, Anguil Environmental is partnering with Siemens to discuss exciting developments in the world of technology and environmental equipment: Empowering Environmental Technologies with the IIoT.

What is the Industrial Internet of Things (IIoT)?

Anguil’s control systems already provide the safest, most efficient, and highly reliable operation while integrating smoothly into existing plant operations. Anguil is now trailblazing the technological advancement of environmental equipment with the Industrial Internet of Things (IIoT) to improve safety, reliability, and maintenance efforts.

What will you learn in this webinar?

- How can you be sure your environmental technologies are in compliance?

- What is the risk of not leveraging sensors and smart devices in decision making?

Manufacturing facilities are increasingly being designed with sensing devices that employ a central control system to remotely monitor and adjust equipment within the plant and beyond. The transparency provided via the IIoT (Industrial Internet of Things) allows companies to analyze and predict machine behavior to optimize production and processes remotely. However, there are costs, time considerations, and potential pitfalls in system selection and implementation. Plant managers, engineers, and production personnel must carefully consider safety, security, and usability of each remotely monitored device. Compliance adds another layer of complexity when talking about IIoT for environmental technologies.

This webinar will examine, in detail, all the benefits and potential hurdles that industrial facilities should evaluate when implementing remote monitoring on environmental technologies.

REGISTER HERE

4 Qualities to Look for in Your Next Environmental Partner

Leave a CommentNot all environmental technology providers are created equal. How do you ensure you make the smartest choice in such a significant relationship? Start by assessing these four qualities and asking the following questions to any potential environmental technology partner.

1. Engineering Experience and Expertise

Questions to Ask:

- What is the depth of your engineers’ experience?

- How many successful installations do you have in my industry?

- Who will my project manager be, and can I meet them?

2. Quality Design and Manufacturing for System Reliability

Your selected environmental technology partner should have a proven process in place for design and manufacturing processes to ensure

Questions to Ask:

- How is your fabrication process managed?

- What kind of Quality Assurance program is in place?

- What technology is leveraged during system design?

3. Integrated System Controls

When evaluating a potential partner, assess their in-house controls engineering capabilities and success record with integrating multiple equipment packages and process lines. Controls designs should be remotely accessible, resilient to downtime, account for safety and

Questions to Ask:

- How do your controls ensure safe, efficient, and reliable operation?

- What is your experience integrating abatement equipment and process lines?

- What remote connection capabilities are in place?

4. Robust Aftermarket Services Department for All Makes, Models & Manufacturers

A reputable partner should have an accessible aftermarket and service department to maximize system value through preventive and

Questions to Ask:

- Do you have a dedicated Aftermarket department?

- Do you offer 24/7 service support?

- Who will be servicing my equipment? Where are they based?

Anguil’s legacy of broad Industry Experience means our engineering experts are not pigeon-holed to a limited product portfolio to solve every application. Learn more about our System Design & Engineering capabilities and Contact Us to get started on a custom solutions specific to your application.

3 High Payback Oxidizer Retrofits for Lean Budgets

Leave a Comment2020 has been the year many manufacturers have had to pivot into to the unknown. Your pollution control equipment must be considered as you make key business decisions. Whatever your new business landscape, Anguil is ready to assess your current equipment, production requirements, and capacities to develop a strategy that meets your emerging business needs.

Have you had to make any of these business decisions in 2020?

- Adding new process line(s) for expanded or new product offerings

- Consolidating production plants or building new facilities

- Speeding up process lines

- Changed process inputs

In the face of uncertainty and rapid change, strategic investment in your existing pollution control systems can keep you in compliance and offer opportunities for rapid return on investment (ROI). Instead of a new capital equipment purchase, consider retrofitting your existing equipment to fit tight timelines and lean budgets.

Here are three high payback equipment retrofits to consider.

Increase Capacity to Accommodate Production Changes

Add more flow to your existing oxidizer.

Anguil makes it easy to reimagine the possibilities of your pollution abatement equipment. If you have had to expand or consolidate production lines, you can retrofit your existing equipment to treat additional flow.

How to Evaluate Capacity Changes

Is the new flow over capacity of existing unit?

When evaluating capacity modifications, start by determining your current state and comparing it with the future.

- Confirm existing flow, VOC loading, and temperature to oxidizer

- Confirm new flow, VOC loading, and temperature to oxidizer

Can modifications be made to the existing unit to increase capacity?

Most of the time, the answer is yes. Review the VOC loading and confirm it does not exceed capacity of the unit type. Anguil’s engineering experts can help you confirm your capacity modification possibilities.

What components need to be upgraded to increase RTO capacity?

Once your capacity parameters are determined, several components need to be evaluated to accommodate the flow expansion.

- Upsize the Burner: Review burner system, fuel train, SFI

- Change Media Design: Review media bed design – size, depth, type of media, velocity, TER, and pressure drop, residence time

- Upsize Fan: Review fan/VFD sizing – flow, temp and pressure rating

- Add an Emission Concentrator: Reduce the flow to your oxidizer by concentrating large flows of low concentration air upstream of the inlet

Reduce Downtime with Controls Upgrades + Strategic Spares Management

Prepare for the unexpected with modern controls and critical spares

Like an insurance policy, the savviest oxidizer operators invest great care in preventive safeguards for resiliency in the face of unexpected downtime. Two high impact, low effort investments you can make to reduce downtime are oxidizer controls upgrades and strategically stocking your spare parts inventory.

Controls Upgrades

Because your oxidizer controls will generally function without incident even with older software and hardware, you may not consider them an upgrade or replacement priority. That is, until you experience a lengthy downtime due to a PLC crash or not having spares for an obsolete system.

Anguil has extensive experience consulting with operators on their oxidizer controls needs and developing custom solutions to prevent unplanned downtime, safety and compliance risks, and obsolete part headaches.

Are you ordering replacement control panel parts from Ebay? Or struggling to find support for your obsolete control components?

While obsolete parts may function, they expose you to many risks ranging from lengthy downtime to lack of service support. Because

Answer: Anguil Aftermarket can help identify which components are slated to be discontinued by completing a Controls Review of your current installed components and make Controls Upgrade recommendations

Is your PLC or HMI exhibiting signs of vulnerability, such as program loss or failure?

A failed display can leave you blind when it comes to operating your oxidizer system safely. If this happens at an inopportune moment, you want to be prepared to download your HMI program to a replacement display from your spare parts inventory.

Answer: Anguil Aftermarket can perform PLC Upgrades, even if source code is unavailable. Our electrical and field service engineers will specify, supply, and install replacement hardware and supply and commission new software.

Are your oxidizer controls upholding your safety commitment?

Even if your system is using aging or obsolete components without issue, your system may not be meeting modern safety standards.

Answer: Anguil Aftermarket can review your program logic, make Operational Efficiency and Safety Improvements, and develop a custom solution.

Do you wish you had clearer insight into the workings of your oxidizer’s PLC? What if your oxidizer’s controls could be e

Hardware improvements such as a Human Machine Interface (HMI) Upgrade can provide better system control and visibility on machine operation and troubleshooting via improved graphics and diagnostics.

Answer: Anguil Aftermarket employs a user-friendly 10” HMI option that provides easy operation with a graphical overview with process values, loop bar graphs, trends, and I/O and purge interlock status. Additional upgrades such as Digital Chart Recorders and Remote Ethernet Access can unlock the full potential of modern oxidizer control technology.

Stocking Your Spare Parts Inventory

Why does my oxidizer spare parts program deserve significant attention?

- Uptime – The downtime associated with a system upset can be dramatically reduced if the right parts are immediately available on site.

- Compliance – Stocking an appropriate level of spare parts for your oxidizer system may be required by your envir

onmental permit.

- Preparedness – Making the decision to have a well-stocked spare parts inventory could be the difference between having the needed component available in your stockroom to get your system quickly back online versus lengthy downtime, lost production revenue, and plant headache.

- Mission – Stocking an appropriate level of spare parts for your system is a vital step in a long-term commitment of environmental compliance.

How Does Anguil Determine my Recommended Spare Parts List?

Using your system process and instrumentation diagram (P&ID) and bill of materials (BOM), Anguil’s Aftermarket Experts can design a custom-tailored recommended Critical Spare Parts Package for you. Yes, we can do this for any oxidizer system regardless of manufacturer! Plus, we can supply parts for your ancillary equipment including scrubbers, concentrator wheels, and dust collectors. We tag each system component as falling into one of four categories: CRITICAL, RECOMMENDED, CONVENIENCE, and WHEN NEEDED.

| Level | Description | Examples |

| Convenience | Consumables not critical to system operation | Filter elements, door gasket |

| Critical | High-use and high-wear parts that are vital to system operation, parts that may have a long lead-time | Actuators, poppet valve components, thermocouples, flow sensors, and spark igniters |

| Recommended | These items are not typically known to fail; however, they cannot safely be bypassed if they do | Air proving switches, PLC components, and fuel train components |

| When Needed | Parts that are unlikely to fail or not generally critical to system operation | Burners, gauges, and flex joints |

What is a Critical Spare Parts Package?

A critical spare parts package bundles the most critical spare components for your system at a discounted price.

Why should I consider a Critical Spare Parts Package?

This convenient package takes the guesswork out of ordering spare parts and saves you money. In addition to meeting compliance requirements and strengthening your downtime firewall, we discount this package over the cost of ordering individual parts.

Why order spare parts through Anguil?

Anguil can simplify your parts procurement process. We know your system, so let us quickly get you the parts you need. If we don’t know your system, our engineering experts can quickly assess your system and determine your parts needs. Anguil has an expansive network of vendor relationships and enjoys priority service and advantageous pricing that we pass on to you.

Increase Thermal Energy Recovery (TER) for High Impact ROI

Improving TER with a media upgrade

Considering some enhancements to your RTO? Your RTO’s media is a key target area for high return on investment (ROI). Many operators consider media replacements primarily out of necessity due to plugging, but a lot of potential upside may be available by focusing on your media’s TER performance. Consider this:

- Up until recently, most RTOs were designed with 95% Thermal Energy Recovery (TER%) or less.

- Rule of Thumb for a self-check: If the average RTO outlet temperature is more than 100°F higher than the RTO inlet temperature, your actual TER% is probably less than 95%.

- Even a small increase in TER% can have a dramatic effect on RTO fuel usage. In some cases, a bump in TER% could eliminate RTO fuel use entirely.

- Advances in ceramic media have allowed Anguil to improve TER% in RTOs by only replacing a portion of the existing ceramic media beds, improving payback periods.

- Anguil has performed this retrofit on numerous RTOs, regardless of original manufacturer, and we offer free Savings Cost Analysis making it easy to get started.

How to Evaluate a Media Design Change

What is my current media design?

Start by determining your current state and comparing it with available possibilities. When evaluating your current media bed design, take note of the following:

- Type of media

- Bed dimensions

- Available space

What is my current media performance?

Next, determine your current process conditions to calculate your media’s current performance.

- Airflow

- Inlet temp

- VOC loading

- Combustion air from burner

- Current fan sizing and speed

What are my new design possibilities?

Look at different media suppliers and what designs are available. Important parameters to keep in mind

- Pressure drop across media beds – will it impact fan speed and possibly sizing?

- Total flow that needs to be treated – will it impact pressure drop and velocity through media?

How much savings can I expect?

The cost of your media retrofit versus your projected fuel savings will determine your ROI. For a free assessment and consultation, complete our Savings Cost Analysis. Upon submittal, an Anguil Aftermarket expert will contact you for a follow-up consultation.

As a custom solutions provider, Anguil’s team of experienced engineers will partner with you to understand your system, regardless of make, model, configuration, or manufacturer, tailoring your retrofit project to maximize system performance. Contact us to get started on your high impact retrofit project.

Addressing India’s Air Pollution Control Needs

Leave a CommentIn response to increased demand for its environmental technologies and services, Anguil Environmental Systems Inc. (Anguil) is

Anguil has been serving the global air pollution control market since 1978. With well-established partners already in place and several successful installations throughout India, company executives felt the time was right. “Forming a subsidiary of the United States parent has always been part of the company’s overall international strategy” said Chris Anguil, President of Anguil Environmental. “After successfully penetrating the European and Asian markets, we knew India was a priority given the growing demand for pollution control solutions.”

Having an established company in the local market allows Anguil technologies to be manufactured utilizing local resources while avoiding substantial international freight costs and duties. Customers can expect a responsive, single source provider for their specific pollution control needs. With a dedicated local team of technical sales, engineering, and service resources at the ground level, the company seeks to serve the nation with the best technology at affordable price.

Make sure to visit our company directory to contact our team in India or see a list of all Anguil locations.

Company Commitment During COVID-19

Leave a Comment

As the world continues to grapple with this pandemic, many federal and state agencies are imposing shelter in place restrictions to prevent the spread of Coronavirus. We understand that many of our customers are considered essential businesses in critical infrastructure industries such as Chemical, Defense, Industrial, Energy, and Transportation, and therefore cannot cease operations.

Our number one priority will remain the health and well-being of our team, while doing whatever possible to service our customers, their facilities and production. We are dedicated to remaining flexible in our approach and adjusting accordingly to keep them operational.

- Our entire service team and support staff remains healthy and is setup online, ready to assist you via remote connection or teleconferencing. For customers requiring onsite services, we are investigating each situation on a case-by-case basis so please contact our service department.

- As a provider to critical business sectors we will continue to operate all of our fabrication facilities including those locations where the population has been placed under a ‘stay at home’ order. Anguil fabrication facilities will remain open as long as possible for any emergency fabrication needs while trying to maintain production schedules.

- We have implemented a work from home policy for all non-essential employees in Accounting, Administration, Purchasing, Sales and Marketing. All individuals in these departments can be reached via phone or email.

- Our purchasing department is maintaining constant contact with our major supply chain partners to ensure the continued flow of products and services.

For 40 years and counting, Anguil has taken on complex environmental challenges and stood strong for our customer. That will not change in the face of these unprecedented times.

Should you have any questions, please call the corporate office (800-488-0230). This is a very fluid situation so please revisit this page for future updates.

Chris Anguil, President-Anguil Environmental Systems

Federal Environmental Advisory Committee Appoints Kevin Summ

Leave a CommentAnguil Environmental is very proud to announce that our Director of Marketing, Kevin Summ, was recently selected by the Secretary of Commerce to serve on the Environmental Technologies Trade Advisory Committee (ETTAC) for a second two-year term. Under the guidance of the United States Department of Commerce, Kevin and his fellow committee members will advise government officials on environmental technologies, trends, policies and markets to improve our nations’ reputation as an international leader.

“Being one of only forty people appointed to ETTAC speaks to Kevin’s experience with the promotion of sound environmental technologies and his dedication to protecting our environment.” said Chris Anguil, President of Anguil Environmental Systems. “As a company, we are happy to sponsor Kevin’s involvement in ETTAC as their mission coincides with Anguil’s pledge to provide environmental and energy solutions that ensure cleaner air and water for future generations.”

More information on committee members and the 2018-2020 and 2020-2022 charters can be found on the International Trade Administration website: https://www.export.gov/ettac

The ETTAC welcomes comments and suggestions from the public. If you wish to make a comment for consideration by the Committee, or for information about previous ETTAC charters, please contact Victoria Yue at victoria.yue@trade.gov.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

EtO is everywhere – in the news, on the minds of the community, and at the forefront of regulators attention.

onmental permit.

onmental permit.